Tachometers are essential devices in various industries. They help in the measurement and monitoring of rotational speeds, which is vital for maintaining optimal performance and avoiding malfunctions.

This article explores the importance and functionality of tachometers in detail, offering insights for both beginners and seasoned professionals.

Introduction to Tachometers

Tachometers are instruments used to measure the rotational speed of an object, often expressed in revolutions per minute (RPM). These devices are crucial in applications ranging from automotive to industrial machinery.

Types of Tachometers

Mechanical Tachometers

Mechanical tachometers use physical mechanisms to measure rotational speed. They are often considered more reliable in harsh conditions.

Digital Tachometers

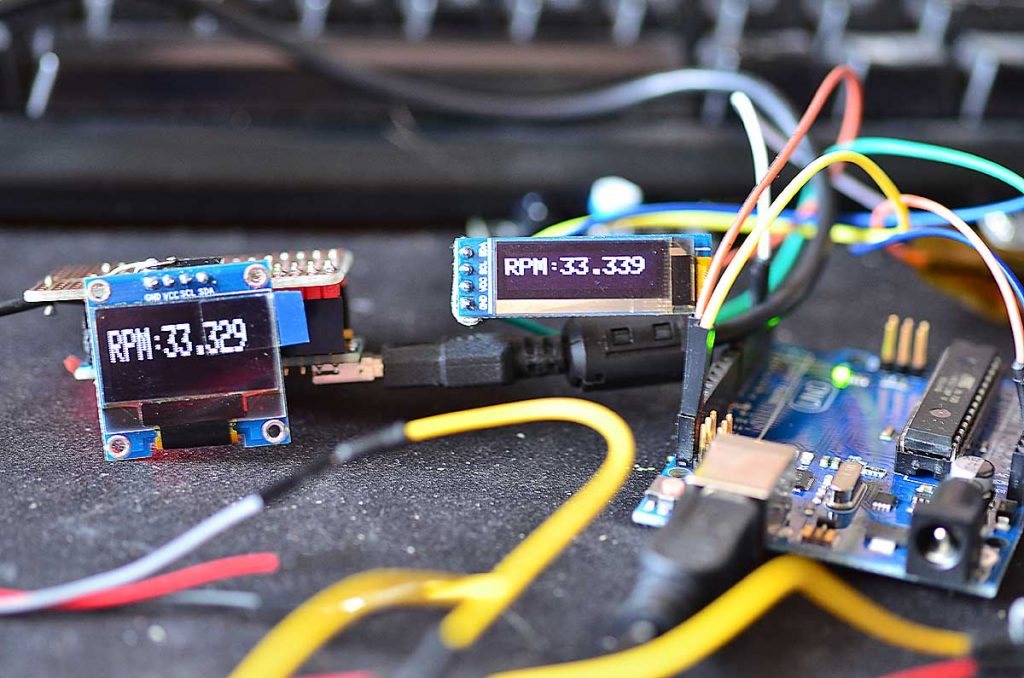

Digital tachometers provide more precise readings and often come with additional features like memory storage and data logging.

Primary Function

The primary function of a tachometer is to measure the rotational speed of a shaft or disk. This measurement helps in monitoring the performance and health of the machinery.

Applications in Various Industries

Automotive Industry

In the automotive industry, vehicles use tachometers to monitor engine speed, ensuring optimal performance and fuel efficiency.

Manufacturing

Industrial machines use tachometers to monitor the speed of rotating parts, especially critical in precision machining and assembly lines.

How Does a Tachometer Work?

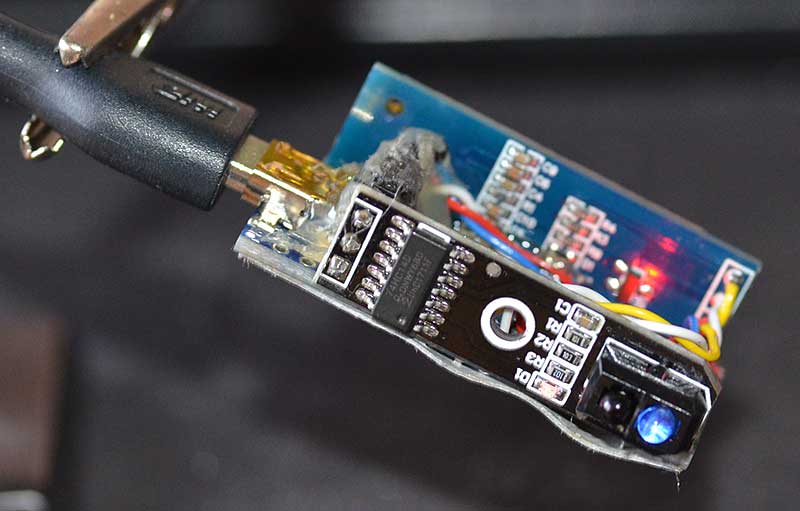

A tachometer typically consists of a sensor and a display unit. The sensor detects the rotation, while the display shows the RPM value.

Benefits of Using a Tachometer

Using a tachometer helps improve efficiency and prolong the lifespan of machinery by ensuring they operate within safe speed ranges.

Choosing the Right Tachometer

When choosing a tachometer, consider factors like the type of machinery, operational conditions, and accuracy requirements.

Installation and Maintenance

Proper installation and regular maintenance are crucial for the accurate functioning of a tachometer.

Key Technological Advancements

Modern tachometers come with advanced features like wireless connectivity and real-time data analysis.

Role in Quality Assurance

Tachometers play a significant role in quality assurance by ensuring machinery operates within the specified speed ranges, reducing the risk of defects.

Common Issues and Troubleshooting

Common issues with tachometers include sensor malfunctions and inaccurate readings. Regular calibration and maintenance can help mitigate these problems.

Case Studies

Numerous industries have successfully implemented tachometers, resulting in improved operational efficiency and reduced downtime.

Future Trends

The future of tachometers looks promising with the integration of IoT and AI for more intelligent monitoring solutions.

Conclusion

Understanding what a tachometer measures and its importance can significantly benefit professionals in various fields, from automotive to industrial manufacturing.

FAQs

What is a tachometer used for?

A tachometer is used to measure the rotational speed of an object, usually in RPM.

Can I use a tachometer on any machine?

Yes, but you must choose the right type of tachometer compatible with your machine’s specifications.

How often should I calibrate my tachometer?

Frequency of calibration depends on usage, but it’s generally recommended to calibrate once a year.