The aviation industry is a marvel of modern technology, innovation, and precision. One instrument crucial to aircraft performance is the tachometer. So, what is a tachometer in aviation? The tachometer, a vital instrument found in virtually every aircraft, measures the rotational speed of the engine’s crankshaft. This instrument is essential for pilots to ensure the aircraft engine operates efficiently and safely.

The importance of tachometers in aviation cannot be overstated. From commercial airliners to private jets, knowing the engines speed in real-time helps pilots make informed decisions, ensuring the safety of all passengers onboard. Let’s delve into the fascinating world of aviation tachometers.

The Evolution of the Tachometer

Tachometers have come a long way since their inception. Initially used in industrial applications, their significance in aviation became apparent as aircraft engines evolved in complexity. Early models were mechanical, using a spinning magnet and a coil to generate a readable output. Over the years, we have transitioned to digital tachometers, providing more precise readings and enriched functionalities.

Types of Tachometers in Aviation

Mechanical Tachometers

Mechanical tachometers were among the first instruments used to measure rotational speed. These devices typically include a rotating magnet mechanism that generates a current. The intensity of the current correlates to the engine’s RPM (revolutions per minute), providing pilots with an analog reading.

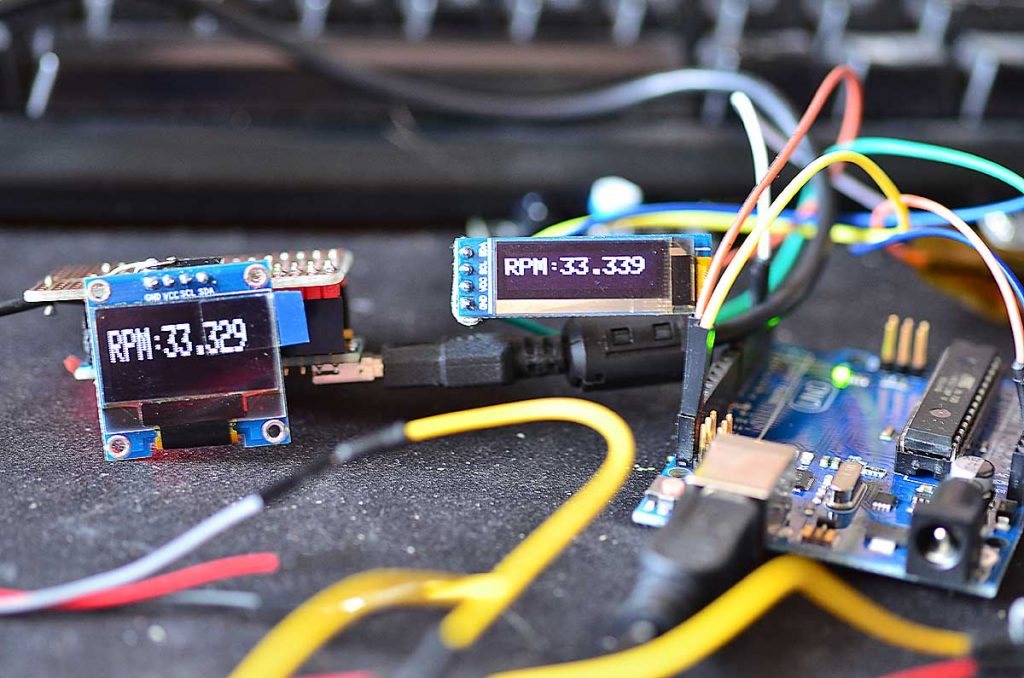

Digital Tachometers

Digital tachometers are the modern counterparts to mechanical systems. They use electronic methods to gauge engine speed and relay the information on a digital display. The accuracy and reliability of digital tachometers have made them the preferred choice in contemporary aviation.

Contact Tachometers

Contact tachometers require physical contact with the rotating component to measure its speed accurately. These are often used in engine testing and maintenance rather than in live-flight applications.

Non-contact Tachometers

Non-contact tachometers use laser or infrared technology to measure rotational speed from a distance. These devices are incredibly accurate and useful in modern aircraft maintenance procedures.

How Does a Tachometer Work?

A standard tachometer system comprises a sensor, a signal processor, and a display unit. The sensor detects the rotational speed of the engine’s crankshaft. This information is relayed to the signal processor, which converts the analog signal to a digital format for the display unit.

The Sensor

The sensor is responsible for detecting the motion and speed of the engines rotating elements. Different types of sensors are used based on the specific application, including magnetic, inductive, and optical sensors.

Signal Processing

The detected signal is processed and converted from an analog format to a digital signal. This conversion is crucial for providing an accurate readout on the display unit.

Display Unit

The processed data is displayed on a screen, providing real-time information about the engine’s RPM. Modern systems often include additional functionalities, such as data logging and trend analysis.

Importance of Accuracy in Aviation Tachometers

In aviation, even minor inaccuracies can have significant consequences. Considerations around the accuracy of a tachometer include:

- Engine performance monitoring

- Fuel efficiency

- Safety of flight operations

- Predictive maintenance

Ensuring these instruments are calibrated and maintained regularly is essential for safe and efficient flight operations.

Aviation Standards and Regulations

The aviation industry is tightly regulated, and tachometers must adhere to stringent standards. Regulatory bodies like the Federal Aviation Administration (FAA) enforce guidelines to ensure these instruments meet the required benchmarks for accuracy and reliability.

Maintenance and Calibration

Routine Checks

Regular maintenance checks are crucial for keeping tachometers in optimal working condition. These checks involve verifying the instrument’s accuracy and calibrating it as needed.

Calibrating a Tachometer

Calibration involves adjusting the tachometer to reflect the accurate rotational speed of an engine. This process may require specialized tools and expertise, ensuring the device remains compliant with aviation standards.

Common Issues with Tachometers

Inaccurate Readings

Inaccurate readings can arise from various issues, including sensor malfunctions or signal processing errors. Regular maintenance can mitigate these risks.

Display Failures

Digital displays can sometimes fail, making it crucial to have backup systems in place. Many modern aircraft incorporate redundant systems to ensure continuous monitoring.

Future of Tachometer Technology in Aviation

With the advent of advanced technologies, the future of tachometers in aviation looks promising. Innovations in sensor technology, data analytics, and real-time monitoring are likely to drive the next-generation tachometers. These advancements will further enhance the safety and efficiency of flight operations.

Why Pilots Trust Tachometers

Pilots rely on tachometers to make critical decisions regarding engine performance. The accuracy and reliability of these instruments are paramount for safe and efficient flight operations.

Enhancing Pilot Training

Incorporating advanced tachometer systems in pilot training programs can significantly enhance the quality of training. These systems provide real-time feedback, allowing trainee pilots to gain a better understanding of engine dynamics.

Advanced Tachometric Solutions in Aviation

Modern tachometric solutions offer a range of functionalities, including:

- Real-time data logging

- Trend analysis

- Predictive maintenance

- Enhanced sensor accuracy

Integrating with Other Systems

Advanced tachometers can be integrated with other onboard systems, such as fuel management and flight control systems, offering a holistic approach to aircraft monitoring and performance optimization.

Three Interesting Facts About Tachometers in Aviation

- The first mechanical tachometers were adapted from industrial machinery applications and were used in the early 20th century airplanes.

- Modern digital tachometers can store data from multiple flights, enabling detailed performance analysis.

- Some advanced tachometers can alert pilots of potential engine issues before they become critical, enhancing flight safety.

External Resources

For more detailed insights into the function and types of tachometers, you can visit this tachometer overview.

Internal Resources

FAQ Section

What does a tachometer measure in an airplane?

A tachometer measures the engine’s rotational speed, specifically the RPM (revolutions per minute) of the crankshaft. This measurement helps pilots monitor engine performance in real-time.

Why is a tachometer important in aviation?

A tachometer provides critical information about the engine’s operational status, enabling pilots to make informed decisions about flight performance and safety.

How often should tachometers in aircraft be calibrated?

Tachometers should be calibrated according to the manufacturer’s recommendations and regulatory guidelines, typically during routine maintenance checks.