Understanding what is a normal tachometer reading is crucial for many professionals and enthusiasts in the automotive and manufacturing industries. A tachometer is an essential instrument designed to measure the rotational speed of a shaft or disk, commonly found in vehicles, medical equipment, and industrial machines.

Introduction to Tachometers

A tachometer can be viewed as the heart monitor of any revolving part of a machine. In cars, for instance, it’s found on the dashboard and indicates the engine’s RPM (revolutions per minute). Understanding normal tachometer reading ensures that engines run efficiently and safely.

History and Evolution

The concept of measuring rotational speed dates back to the 19th century. The original mechanical tachometers evolved into digital versions found in modern vehicles today.

Mechanical Tachometers

Initially, tachometers were purely mechanical devices. They used a flexible, rotating shaft connected directly to a gauge on the dashboard.

Digital Tachometers

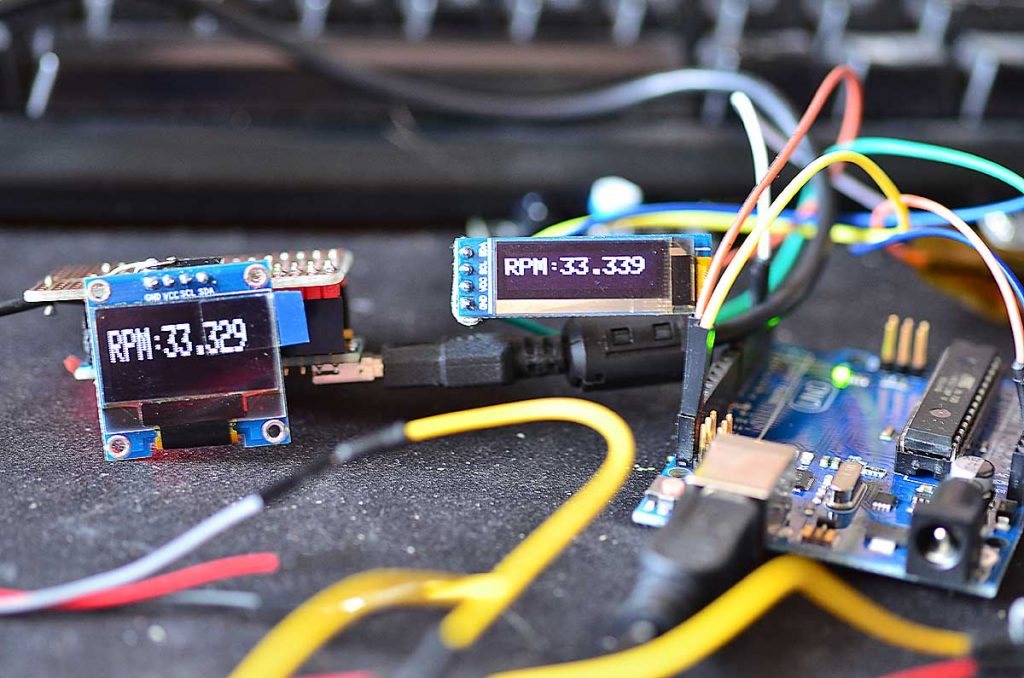

As technology advanced, digital tachometers became more prevalent. They offer greater accuracy and additional functionalities compared to their mechanical predecessors.

How Tachometers Work

Both mechanical and digital tachometers aim to measure RPM. However, their mechanisms differ.

Mechanical Mechanism

A rotating flexible shaft drives the gauge needle on the dashboard.

Electronic Mechanism

Modern digital tachometers measure rotation using sensors and display the RPM digitally. Check this resource for more information on how electronic tachometers work.

What Defines a ‘Normal’ Tachometer Reading?

A ‘normal’ tachometer reading varies depending on the type of engine and its operational context. For instance, cars generally have a normal idle speed of 600-1000 RPM.

Cars

For most cars, a normal idle speed ranges from 600 to 1000 RPM. When the car is in motion, this reading can go up to between 2500 and 3000 RPM for highway driving.

Industrial Machines

Industrial equipment may have a different set of RPM standards. Normal readings can vary widely based on the application.

Aviation

Aircraft engines have their own set of standards. Depending on the phase of flight, the engine RPM can range significantly.

Importance of Monitoring Tachometer Readings

Regularly monitoring tachometer readings ensures the health and efficiency of engines. Abnormal readings can indicate various issues like misfires or engine overloading.

Early Detection of Issues

Monitoring RPM can help detect engine problems early, allowing for timely maintenance.

Fuel Efficiency

Keeping an eye on RPM ensures optimal fuel consumption, which is vital for both cost-saving and environmental reasons.

Maintaining Your Tachometer

Regular maintenance is critical for ensuring accurate tachometer readings. Calibration and sensor checks are necessary steps.

Calibration

Regularly calibrate your tachometer to ensure its accuracy.

Sensor Maintenance

Check and clean tachometer sensors to avoid erroneous readings. Explore more about maintenance techniques.

Types of Tachometers

There are various types of tachometers, each suited for specific applications: mechanical, digital, and contact/non-contact tachometers.

Contact Tachometers

These measure the RPM by physically touching the rotating part.

Non-contact Tachometers

Use a laser or other sensor to measure the rotational speed without direct contact.

Digital Tachometers

Both contact and non-contact versions offer digital readings.

Applications Across Different Industries

Tachometers are used across various sectors.

Automotive Industry

Essential for monitoring engine RPM.

Medical Field

Used in equipment where precision is crucial.

Industrial Applications

Vital for machinery to function correctly.

Conclusion

Understanding what is a normal tachometer reading is crucial for various fields. Accurate tachometer readings ensure engine health, fuel efficiency, and safe operation. For more information, check this Wikipedia article.

FAQs

What is a normal tachometer reading for my car?

Typically, normal idle speed ranges from 600 to 1000 RPM.

How often should I calibrate my tachometer?

It’s best to calibrate your tachometer annually or according to manufacturer guidelines.

Can I use a digital tachometer for industrial applications?

Yes, digital tachometers are commonly used in various industrial settings for their accuracy.

Explore more about tachometer readings and their applications across different industries.