The use of technology in aviation has always been a subject of great interest, especially when it comes to engine performance. One of the essential components recognized in this field is the tachometer. Particularly on an axial-compressor turbine engine, the tachometer serves a critical role. But what exactly is its purpose?

An axial-compressor turbine engine is a crucial piece of aviation technology, and its performance is closely monitored by industry QA professionals and engineers. The tachometer, often referred to simply as the ‘tach,’ is the instrument responsible for measuring the rotational speed of the engine’s compressor.

Understanding the Axial-Compression Turbine Engine

Before diving deep into the role of the tachometer, it’s essential to understand what an axial-compressor turbine engine is. This type of engine is commonly used in aircraft, primarily because of its efficiency and power.

An axial-compressor turbine engine works by initially compressing air as it passes through multiple stages of rotating and stationary blades. The compressed air is then mixed with fuel and ignited in the combustion chamber, producing a high-speed stream of gases that spin the turbine. The turbine, in turn, drives the compressor and generates thrust for the aircraft.

The Tachometer: Measuring Rotational Speed

The primary purpose of the tachometer in this context is to measure the speed at which the engine’s compressor is rotating. Why is this important? Because the speed of the compressor directly impacts engine performance, fuel efficiency, and overall safety.

Engine Performance

Monitoring the rotational speed with a tachometer allows pilots and engineers to ensure that the engine is running within its optimal parameters. If the engine rotates too slowly, it may not generate enough thrust, while an excessively high speed could induce overheating or mechanical failure.

Fuel Efficiency

An accurately functioning tachometer enables fine-tuning of the engine to achieve optimal fuel efficiency. When the compressor operates at its ideal speed, fuel consumption is minimized, which is crucial for both cost-effectiveness and environmental sustainability.

Safety

Safety is paramount in aviation, and the tachometer plays a significant role in ensuring that. By consistently monitoring engine speed, risks of mechanical issues, such as compressor stalls or turbine failure, can be detected early and mitigated.

Different Types of Tachometers

There are various types of tachometers used in axial-compressor turbine engines, each with its unique features and benefits. Here is an overview:

Mechanical Tachometers

Mechanical models operate through a direct connection to the engine. They use gears and springs to measure rotational speed, offering the advantage of simplicity and reliability. However, they may not be as precise as electronic options.

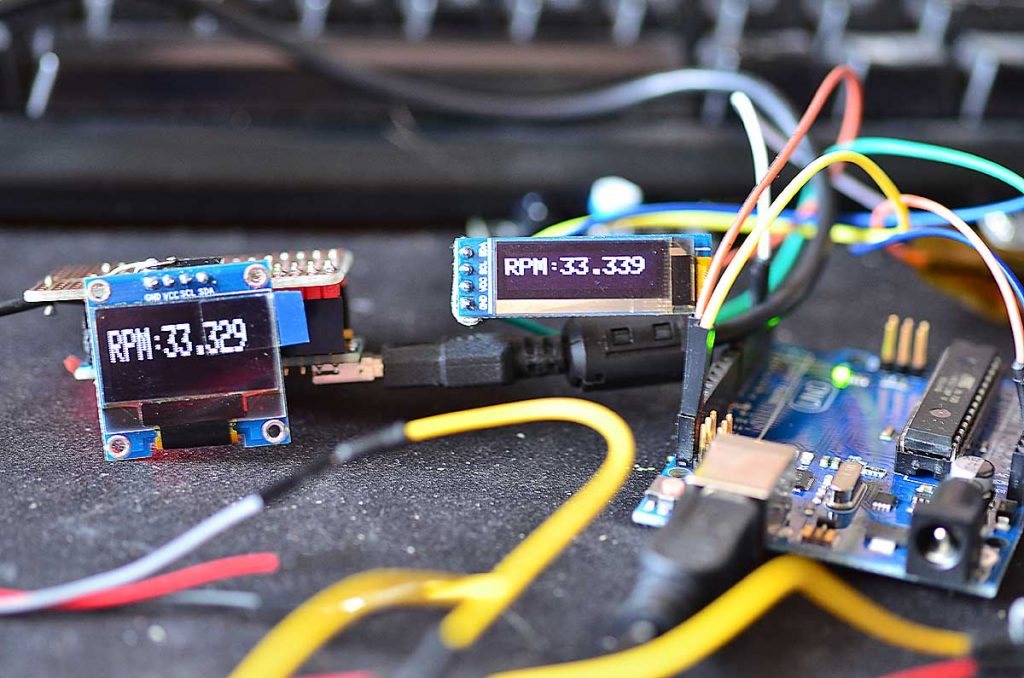

Electronic Tachometers

Electronic tachometers use sensors and electronic circuits to measure rotational speed. They offer higher precision and can be integrated with digital displays and monitoring systems, which makes them a preferred choice in modern aircraft.

Contact and Non-Contact Tachometers

Contact tachometers require physical contact with the rotating part of the engine, which might not be feasible in all situations. Conversely, non-contact versions use optical methods or magnetic fields to measure speed, providing a versatile and often safer alternative.

Applications Beyond Aviation

While tachometers are vital in axial-compressor turbine engines within the aviation sector, their applications extend beyond. They are also used in automotive engineering, marine propulsion systems, and various industrial machinery. In each domain, their purpose remains the samemeasuring and monitoring rotational speed to ensure optimal performance.

Historical Perspective of Tachometers

The history of the tachometer dates back to early steam engines, where measuring rotational speed was crucial for maintaining engine efficiency and safety. With advancements in technology, the function of tachometers has been enhanced, transforming from simple mechanical instruments to sophisticated electronic devices.

The Future of Tachometers in Axial-Compressor Engines

The future holds promising developments for tachometers. Innovations such as smart tachometers integrated with AI and IoT can provide real-time analytics and predictive maintenance, making them an indispensable part of modern aviation.

Furthermore, advancements in material science and electronics will likely yield tachometers that are more durable, lightweight, and precise, thereby enhancing the overall efficiency and reliability of axial-compressor turbine engines.

Conclusion

Understanding what is the primary purpose of the tachometer on an axial-compressor turbine engine is fundamental for industry QA professionals, engineers, and aviation enthusiasts. The tachometer serves as a critical instrument for measuring engine speed, ensuring optimal performance, fuel efficiency, and safety.

Its applications extend beyond aviation, contributing to various fields, and its technology continues to evolve, promising even greater utility and innovation in the future.

FAQ

1. Why is the tachometer important in turbine engines?

The tachometer is crucial for measuring rotational speed, ensuring that the engine operates within optimal parameters for performance, fuel efficiency, and safety.

2. What are the different types of tachometers used in turbine engines?

Common types include mechanical, electronic, contact, and non-contact tachometers, each offering unique advantages and features.

3. How does a tachometer improve fuel efficiency?

By monitoring the engine’s rotational speed, a tachometer enables fine-tuning for optimal fuel usage, minimizing consumption, and ensuring cost-effectiveness.

For more information, you can visit this external link.