How to bench test a tachometer is a question that often arises among industry QA professionals and hobbyists alike. Understanding the precise operation and functionality of a tachometer can save time, money, and ensure the efficiency of your measurement processes. This comprehensive guide is designed to walk you through each step of bench testing a tachometer.

What is a Tachometer?

A tachometer is a device that measures the rotation speed of a shaft or disk, as in a motor. It is an essential tool in many industries including automotive, aerospace, and manufacturing.

Why Bench Test a Tachometer?

Testing a tachometer before installation helps in identifying any defects or inaccuracies, ensuring that it functions correctly when it is in actual use. Bench testing allows you to verify the device’s accuracy, reliability, and performance.

Types of Tachometers

Analog Tachometers

Analog tachometers use a needle and dial to display measurements. They are known for their simplicity and durability.

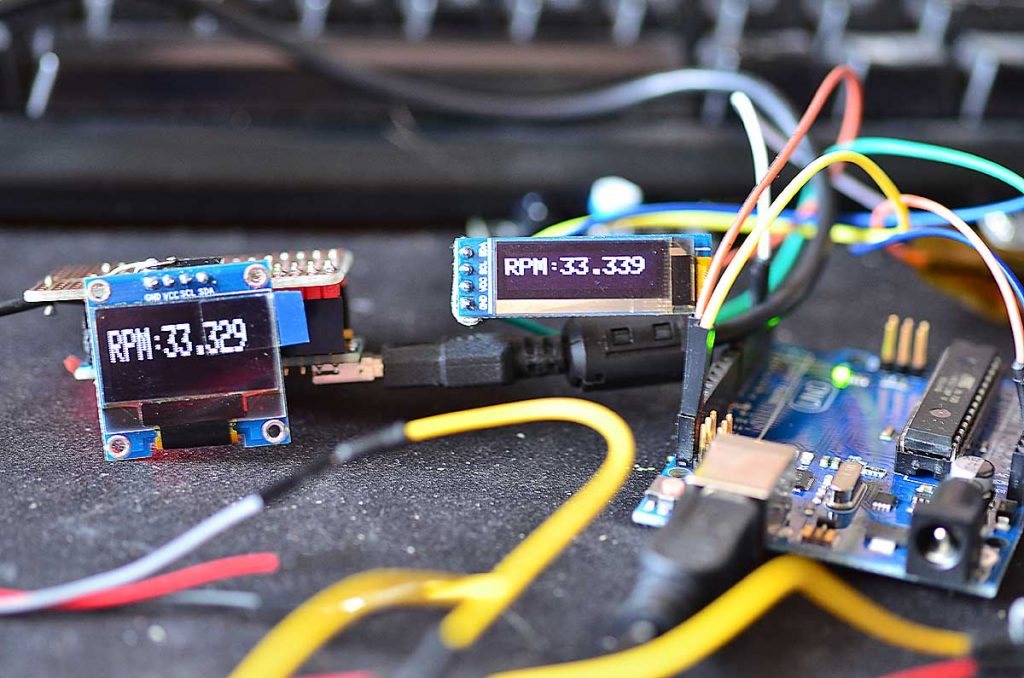

Digital Tachometers

Digital tachometers provide numerical displays, offering better accuracy and ease of readability. They often come with additional features like data logging and connectivity options.

Required Tools for Bench Testing

For bench testing a tachometer, the following tools are typically needed:

- Multimeter

- Signal generator

- Power supply

- Connecting cables

Safety Precautions

Safety should always be your first priority. Ensure that you are wearing the appropriate safety gear and that your workspace is clear of any hazards.

Setting Up the Test Bench

Before you start, make sure you have a well-organized workspace. Keep your tools and equipment within easy reach.

Connecting the Tachometer

The first step is to connect your tachometer to the signal generator and power supply. Make sure all connections are secure and correct.

Calibrating the Tachometer

Calibration is a critical step. Follow the manufacturer’s instructions to calibrate the tachometer accurately. Incorrect calibration can lead to inaccurate measurements.

Running the Test

Once everything is set up, you can start the test. Use the signal generator to simulate the rotational speed, and observe the readings on the tachometer.

Checking for Accuracy

Compare the tachometer’s readings with the signal generator’s output. Ensure that the measurements are within the acceptable range of accuracy.

Troubleshooting Common Issues

No Display

If the tachometer doesnt display any readings, check the power supply and connections.

Inaccurate Readings

If the readings are inaccurate, recalibrate the tachometer and check for any signal interference.

Maintenance Tips

Regular maintenance ensures the longevity and reliability of your tachometer. Keep it clean and check for any signs of wear and tear.

Practical Applications

Tachometers have a wide range of applications in various industries, including automotive diagnostics, manufacturing processes, and even in aviation. Understanding how to bench test a tachometer can significantly improve the operational efficiency in these fields.

Advanced Testing Techniques

For those looking to delve deeper, advanced bench testing techniques can further enhance the accuracy and reliability of a tachometer. This includes using high-precision signal generators and specialized diagnostic software.

FAQ Section

What is the purpose of bench testing a tachometer?

The purpose of bench testing a tachometer is to ensure its accuracy and reliability before it is installed in a real-world application.

Can I use a multimeter to test a tachometer?

Yes, a multimeter can be used to check the voltage and continuity of a tachometer, but a signal generator is required for a complete test.

What should I do if my tachometer shows no reading?

If your tachometer shows no reading, check the power supply and all connections. Recalibrate if necessary.

For related articles, visit stroboscopic detection and Britannica Tachometer.