The realm of measurement tools has seen tremendous technological evolution over the years, and one such innovation is the non contact tachometer. This device serves a crucial role in many industrial applications, primarily used to measure the rotational speed of an object without direct contact. In this article, we will dive deeply into the intricacies of how to use a non contact tachometer and understand its significance. The initial setup and operation techniques will be discussed, ensuring you can utilize this technology effectively in your quality assurance processes.

What is a Non Contact Tachometer?

A non contact tachometer is a device that measures the rotational speed of an object without requiring physical contact. It operates using laser or optical methods to detect the motion of rotating components such as motors, gears, or fans. The absence of physical contact reduces wear and tear, making it ideal for delicate or high-speed applications.

Types of Non Contact Tachometers

- Laser Tachometers

- Optical Tachometers

- Infrared Tachometers

Importance of Non Contact Tachometers in Industry

In the industrial environment, maintaining accurate rotational speeds is paramount for the longevity and efficiency of machinery. Non contact tachometers provide a precise measurement method, reducing the risk of machinery damage due to contact-based methods. They are critical in various industries such as manufacturing, automotive, and aerospace.

Applications in Quality Assurance

Quality assurance professionals rely heavily on accurate measurement tools. Utilizing a non contact tachometer in QA processes ensures that rotational speeds are within specified tolerances, which is crucial for the reliability and performance of different mechanical systems.

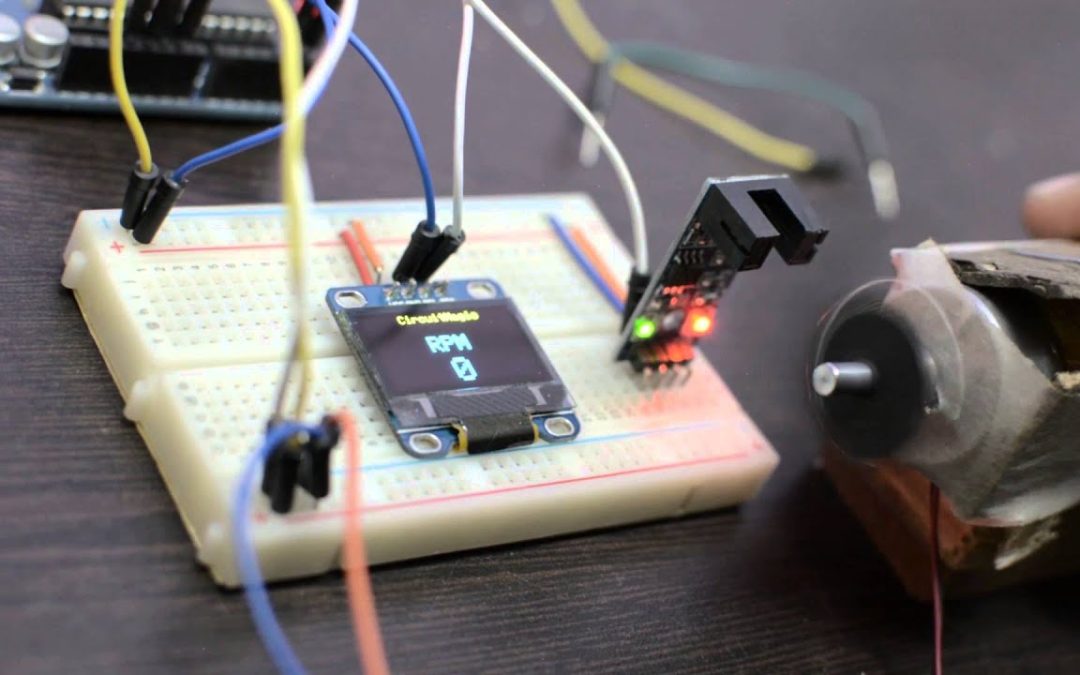

Setting Up a Non Contact Tachometer

The initial setup of a non contact tachometer involves several steps:

- Read the manufacturers manual thoroughly.

- Ensure the device is calibrated according to the specifications.

- Install the reflective tape on the rotating object, if required.

- Power up the tachometer and set the appropriate measurement parameters.

Calibration Process

Calibration is critical for obtaining accurate measurements. Follow these steps for proper calibration:

- Place the tachometer at a specific distance from the rotating object.

- Use a reference speed to adjust the devices readings.

- Regularly verify calibration to maintain accuracy.

Operating a Non Contact Tachometer

Operating a non contact tachometer involves a few simple steps:

- Aim the tachometer at the rotating object.

- Ensure the laser or sensor aligns with the reflective surface.

- Record the rotational speed displayed on the device.

Best Practices for Accurate Measurement

- Keep the device stable during measurements.

- Avoid external light interference.

- Maintain a consistent distance from the rotating object.

Common Mistakes to Avoid

While using a non contact tachometer, it’s crucial to avoid common pitfalls such as:

- Incorrect installation of the reflective tape.

- Ignoring calibration requirements.

- Measuring from an unstable platform.

Troubleshooting Tips

If you encounter issues while using a non contact tachometer, consider these troubleshooting tips:

- Check battery levels and replace them if necessary.

- Ensure the reflective tape is clean and properly attached.

- Verify that the device is correctly calibrated.

Advantages of Non Contact Tachometers

Non contact tachometers offer several advantages:

- High accuracy and precision.

- Reduced wear and tear on components.

- Minimal maintenance requirements.

Disadvantages and Limitations

Despite their benefits, non contact tachometers have some limitations:

- Need for a clear line of sight.

- Potential interference from external light sources.

- Dependence on reflective tape for accurate measurements.

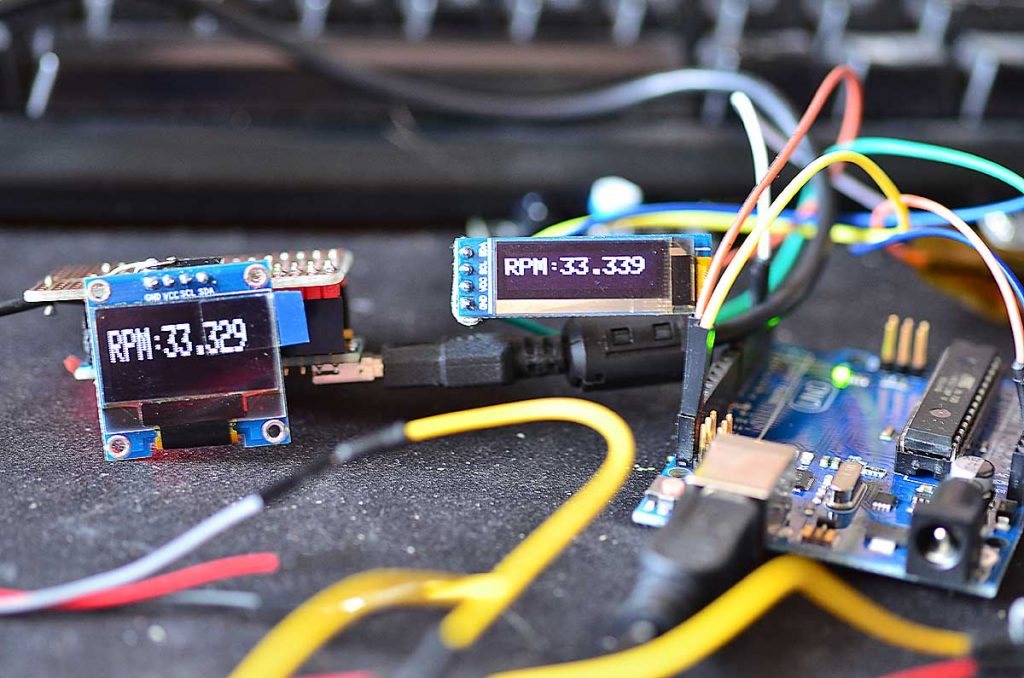

Advanced Features in Modern Non Contact Tachometers

Modern non contact tachometers come with various advanced features, such as:

- Digital displays with backlighting.

- Data logging capabilities.

- Remote monitoring options.

Comparing Non Contact and Contact Tachometers

Comparing non contact and contact tachometers can help you decide which one to use in different scenarios. Non contact tachometers are ideal for high-speed applications, while contact tachometers may be more suitable for lower speeds and direct contact scenarios.

Maintenance and Care

Proper maintenance is essential for the longevity and accuracy of your non contact tachometer. Regularly clean the sensor and ensure the device is stored in a protective case when not in use.

Choosing the Right Non Contact Tachometer

When choosing a non contact tachometer, consider factors such as measurement range, accuracy, and additional features. Reading reviews and consulting with experts can also be beneficial in making an informed decision.

Conclusion

In conclusion, understanding how to use a non contact tachometer is essential for accurate and efficient rotational speed measurements in various industrial applications. By following the guidelines and best practices discussed in this article, you can ensure optimal performance and longevity of your measurement device.

Frequently Asked Questions (FAQs)

What is a non contact tachometer used for?

A non contact tachometer is used for measuring the rotational speed of an object without physical contact, commonly used in industrial settings.

How do you calibrate a non contact tachometer?

Calibration involves adjusting the device’s readings using a reference speed and regularly verifying its accuracy.

What are the advantages of using a non contact tachometer?

The main advantages include high accuracy, reduced wear and tear, and minimal maintenance requirements.

For more detailed technical information, you can visit this Wikipedia page.

Also, explore more about high-speed inspection tools from here and understand their role in quality assurance processes.