Checking engine RPM without a tachometer can be crucial for various applications. Whether you’re a car enthusiast, an industrial worker, or someone interested in engine maintenance, knowing your engine’s RPM can be very beneficial. In this article, we will explore several reliable and accurate ways to measure the RPM of an engine without using a tachometer.

Introduction

Revolutions Per Minute (RPM) is a key metric for understanding the performance of an engine. RPM indicates how many times the engines crankshaft makes one full rotation every minute, which can give you insights into the engine’s health and performance.

Typically, a tachometer is used to measure RPM. However, what if you don’t have a tachometer? What if you can’t use one for some reason? This comprehensive guide will help you out.

Why Knowing Your Engine’s RPM Matters

Engine Performance

Understanding the RPM of your engine allows you to gauge its performance. High RPMs can indicate that the engine is working hard, whereas low RPMs might suggest it’s idle or not performing correctly.

Maintenance Predictions

Regularly monitoring the RPM can provide key insights into when your engine might require maintenance. Changes in the RPM during specific tasks can signal issues that need immediate attention.

Safety Measures

Checking RPM can be pivotal in ensuring the safety of the vehicle or machinery. High RPMs over a prolonged period can be harmful and potentially dangerous.

Methods to Check RPM Without a Tachometer

Using Sound and Frequency

One of the simplest methods to estimate engine RPM without a tachometer is by using sound and frequency.

Materials Needed:

- Smartphone or frequency analyzer

- Calculator

Step-by-Step Guide

- Start the engine and let it idle.

- Use a frequency analyzer app on your smartphone to measure the engine’s sound frequency.

- Most engines have a specific number of cylinders and firing order. Use these values to convert the frequency measured to RPM using a formula.

Using a Timing Light

Another reliable traditional method is using a timing light.

Materials Needed:

- Timing light

- Calculator or RPM conversion chart

- Engine’s service manual

Step-by-Step Guide

- Connect the timing light to the engine as per the manual’s instructions.

- Start the engine and point the timing light at the engines harmonic balancer or any other marked surfaces.

- Count the flashes and use the RPM conversion chart or a simple calculation to determine the RPM.

Using a Multimeter

A digital multimeter that has an RPM function can be highly effective for this purpose.

Materials Needed:

- Digital multimeter with RPM function

- Engine’s service manual

Step-by-Step Guide

- Start the engine and let it idle.

- Set the multimeter to the RPM setting.

- Attach the test leads to the engine as specified in the service manual.

- Read the RPM directly on the multimeter’s display.

Using an Oscilloscope

An oscilloscope is another intricate but accurate tool for this task.

Materials Needed:

- Oscilloscope

- Engines service manual

Step-by-Step Guide

- Connect the oscilloscope to the engines ignition system.

- Start the engine and let it idle.

- The oscilloscope will display waveform and from there, RPM can be calculated.

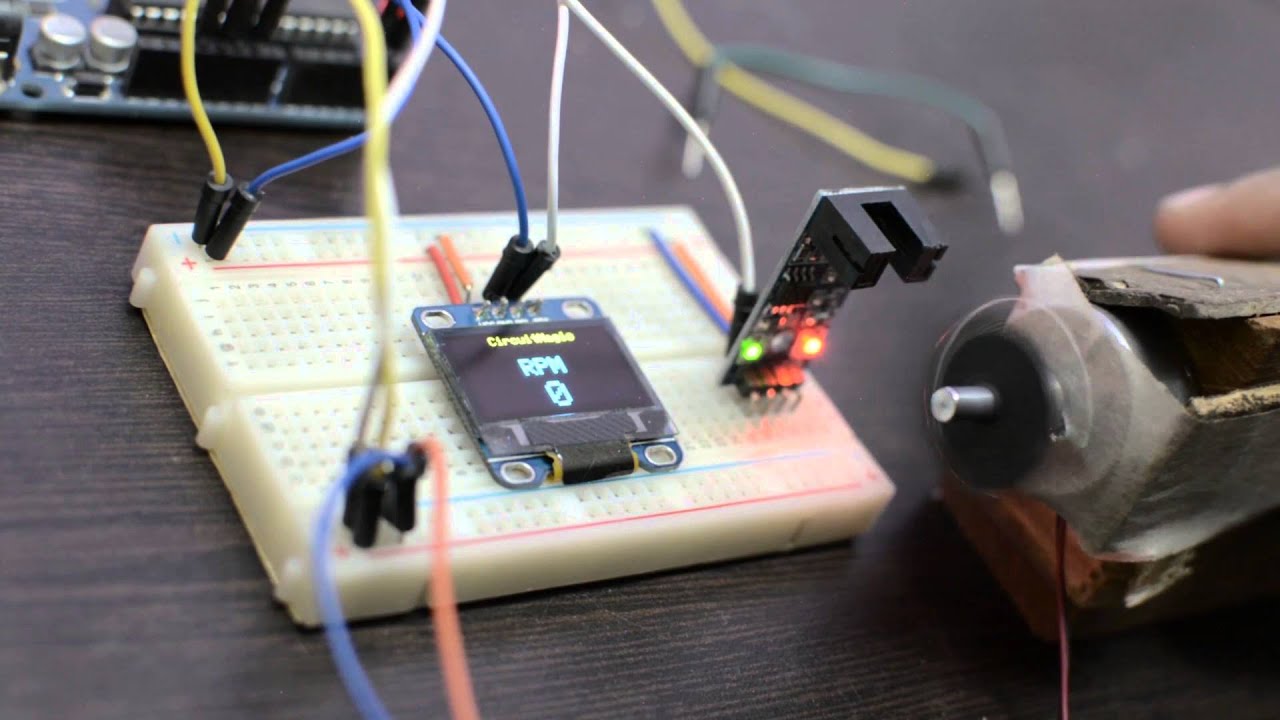

Technological Advances in RPM Measurement

Modern technology has simplified various tasks, and measuring RPM without a tachometer is no exception. This can be particularly interesting for industrial applications:

Smartphone Apps

Numerous apps can measure engine RPM by analyzing the sound frequency of the engine. These apps use your smartphones microphone to deduce the RPM.

Laser Tachometers

Laser tachometers are pocket-sized devices that can measure RPM by simply pointing the laser at a reflective surface on the engine. Refer to ScienceDirect for more details on how laser tachometers work.

Infrared Tachometers

Infrared tachometers function similarly to laser tachometers but use infrared light instead. They are particularly useful in noisy environments where sound-based methods may not be effective.

Applications in Various Fields

Monitoring RPM is not limited to the automotive industry. It finds applications in numerous fields:

Manufacturing Industries

Industries like semiconductor manufacturing and high-speed genetic analysis often require precise RPM measurements. For specific applications, refer to our article on Paint and Coating.

Scientific Research

Research areas like genetic sequencing also benefit greatly from accurate RPM measurements for monitoring equipment performance. Our detailed guide on Genetic Analysis explores this further.

Heavy Machinery

Heavy machinery in construction and farming also needs constant RPM monitoring for longevity and efficiency. Learn more about how this is applied in Semiconductor Manufacturing.

Common Mistakes and How to Avoid Them

Incorrect Attachments

One common mistake is incorrect attachment of measuring tools. Always follow the manufacturers instructions and refer to the engines service manual.

Ignoring Calibration

Ensuring that your tools are calibrated properly is crucial for accurate RPM measurements. Periodic checks and adjustments can enhance the accuracy.

Overlooking Safety

Always prioritize safety by ensuring the engine is off while attaching devices and keeping hands and tools away from moving parts during measurement.

FAQs

1. What is the most accurate method to check engine RPM without a tachometer?

The most accurate method is typically using an oscilloscope, but this also requires specialized knowledge and tools.

2. Can smartphone apps effectively measure engine RPM?

While they may not be as accurate as traditional tools, smartphone apps can provide a fairly reliable estimate of engine RPM.

3. Is it possible to measure RPM on heavy machinery without a tachometer?

Yes, methods like using a digital multimeter or timing light can be used on heavy machinery as well.

In conclusion, understanding how to check engine RPM without a tachometer can be a valuable skill for various industries and applications. By using the methods mentioned in this article, you can confidently monitor your engine’s performance.