In todays fast-paced industrial world, accuracy and precision are necessary. One device that has stood the test of time in ensuring this precision is the tachometer. But what is a tachometer, and how does it play such a vital role, especially for our esteemed Industry QA professionals? Let’s dive into the world of tachometers.

Introduction to Tachometers

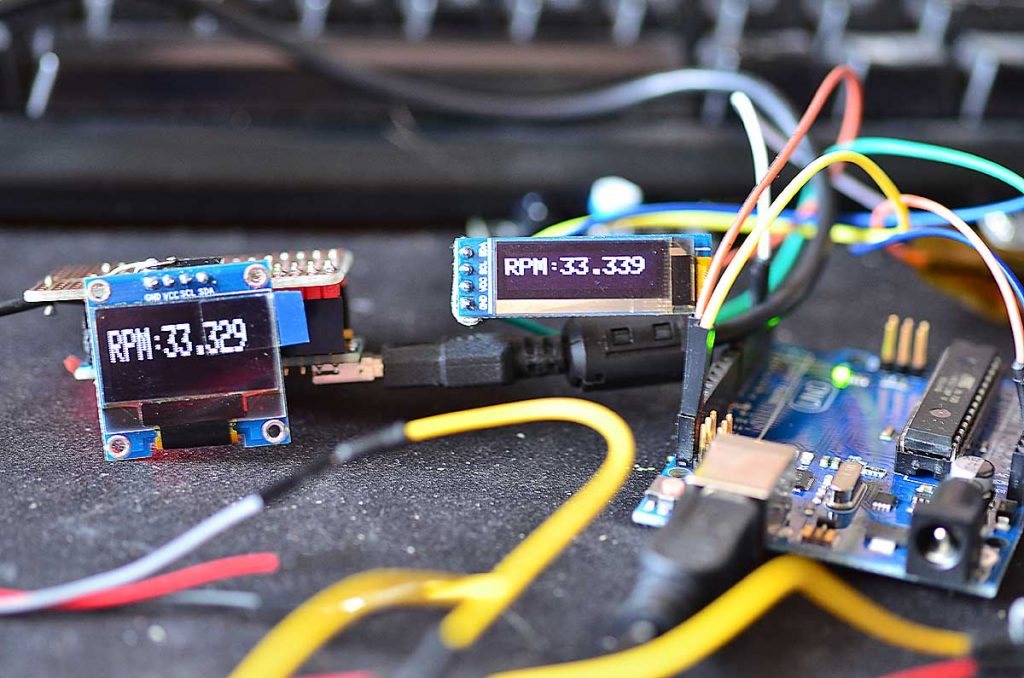

The term tachometer originates from the Greek words ‘tachos’ meaning speed and ‘metron’ meaning measure. Essentially, a tachometer is an instrument used to measure the rotation speed of a shaft or disk, expressed in revolutions per minute (RPM). This device is crucial in various applications, from automotive to industrial machinery.

The Working Principle of a Tachometer

A tachometer functions based on the principle of electromagnetism. When a rotating shaft is coupled with a magnet and coil setup, the produced electrical signal indicates the rotational speed. Modern digital tachometers employ optical sensors, detecting light pulses that generate a digital signal corresponding to the rotational speed.

Types of Tachometers

Mechanical Tachometers

Mechanical tachometers are some of the oldest types. They use a dial and needle to indicate the speed. They function based on the centrifugal force generated by the spinning motion of an internal mechanism.

Digital Tachometers

Digital tachometers are more advanced and provide precise readings using electronic signals. They often come with a digital display, making it easy to read and interpret data.

Contact and Non-contact Tachometers

Contact tachometers require physical contact with the rotating object, while non-contact tachometers use lasers or optical sensors to measure the speed without any physical interface.

Applications in Various Industries

Automotive Industry

In the automotive sector, tachometers are essential for monitoring engine performance. They help in ensuring the engine runs within the optimal RPM range, preventing over-revving and potential damage.

Manufacturing Industry

In manufacturing, tachometers are crucial for monitoring the speed of conveyor belts, rotating shafts, and other machinery, ensuring optimal production speed and avoiding breakdowns.

Medical Equipment

Tachometers also find applications in medical equipment, ensuring devices like centrifuges operate at correct speeds for accurate results.

How to Use a Tachometer

- Ensure the device is calibrated correctly.

- Place the tachometer sensor in the required position.

- Read the displayed RPM value.

Maintenance and Calibration

Like any precision instrument, regular calibration and maintenance of the tachometer are necessary. This process ensures consistent performance and accuracy.

Tachometers and Industry QA Professionals

For Industry QA professionals, the importance of a tachometer cannot be overstated. It helps in ensuring machinery and processes run at the desired speed, maintaining product quality and consistency.

Key Benefits

- Accuracy: Provides precise measurement.

- Efficiency: Ensures machinery runs within optimal parameters.

- Safety: Prevents equipment from over-revving and potential damage.

Common Issues with Tachometers

Despite their reliability, tachometers can encounter issues like:

- Signal Interference

- Calibration Errors

- Mechanical Wear and Tear

Addressing these problems promptly ensures the longevity of the device.

Future of Tachometers

With advancements in technology, tachometers are becoming more sophisticated. Integration with IoT and AI is on the horizon, offering even more precise measurements and predictive maintenance capabilities.

FAQs

1. What is the difference between a contact and non-contact tachometer?

Contact tachometers require physical contact, while non-contact tachometers use optical sensors or lasers.

2. Why is regular calibration important?

Regular calibration ensures the tachometer provides accurate and reliable readings.

3. Can tachometers be used for all types of machinery?

Yes, tachometers are versatile and can be used in various industries, including automotive, manufacturing, and medical equipment.

Conclusion

In conclusion, understanding what is a tachometer and its importance is crucial for Industry QA professionals. This device ensures accuracy, efficiency, and safety in various applications. Embracing advancements in tachometer technology will further enhance its relevance in our fast-evolving industrial landscape.

For more detailed information, visit this resource.

Don’t forget to check out our related articles here.

For more insights on using tachometers in high-speed monitoring, you may also find this article useful.