Lathes are fundamental tools in the world of manufacturing and machining. In this comprehensive guide, we will delve into the intricacies of what are lathes and their tremendous impact on various industries. The evolution of technology has transformed lathes into essential, powerful machines that play a critical role in shaping our modern world.

Understanding the Basics: What are Lathes?

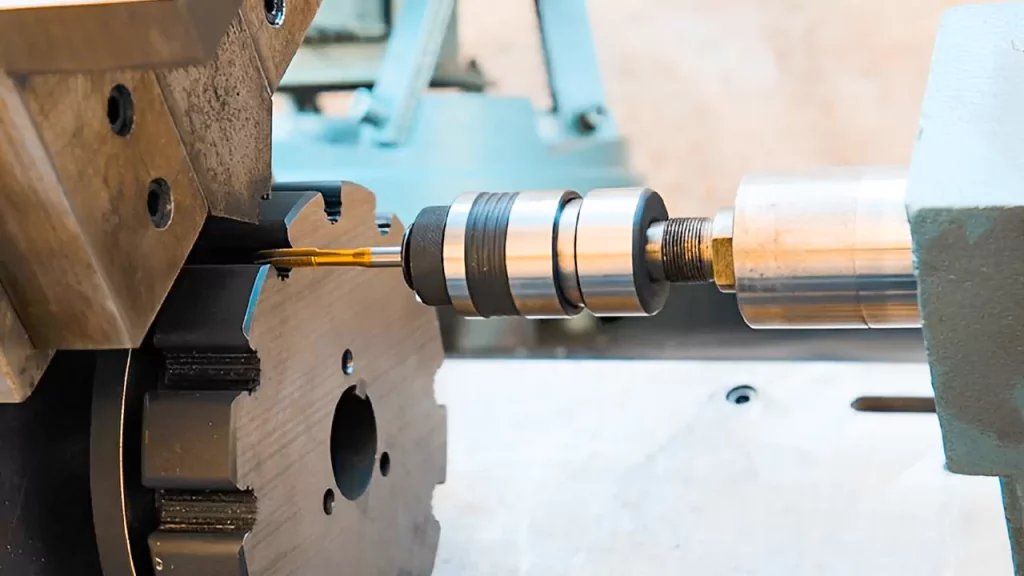

A lathe is a machine tool that is used to shape pieces of material by rotating them around a stationary cutting tool. This process, known as turning, is fundamental in the manufacturing of metal, wood, and plastic products. Lathes are incredibly versatile and are used in a wide range of industries, from automotive manufacturing to woodworking.

The Early History of Lathes

The history of lathes dates back thousands of years. The first known use of lathes was by ancient Egyptians in 1300 BC. These early lathes were simple devices that required manual turning. Fast forward to the Industrial Revolution, and lathes became more complex and efficient, thanks to the introduction of steam power.

The Evolution of Lathes in Modern Times

With the advent of electricity and computerized controls, lathes have undergone a tremendous transformation. Today’s lathes are highly automated and capable of precision work that was unimaginable just a few decades ago. The integration of modern technology has enabled higher productivity and accuracy in machining processes.

Types of Lathes

CNC Lathes

Computer Numerical Control (CNC) lathes are programmed using a computer and can perform highly intricate and precise operations. These lathes have revolutionized manufacturing by enabling consistent, high-quality production runs.

Engine Lathes

Engine lathes are the most common type of lathe and are used for a wide variety of machining tasks. They are versatile machines that can perform tasks such as turning, threading, and drilling.

Turret Lathes

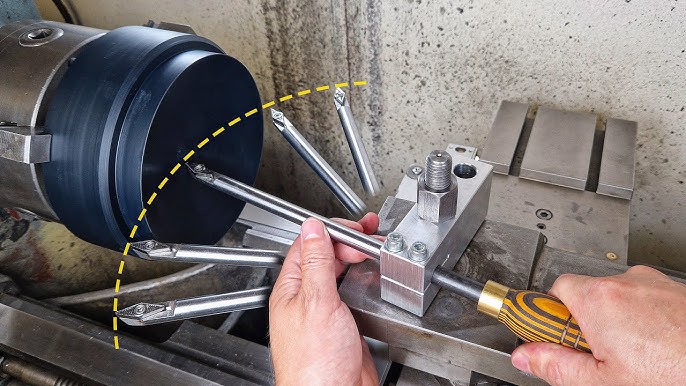

Turret lathes feature a turret that can hold multiple cutting tools, allowing for quick changes between operations. This makes them ideal for high-volume production runs.

Special Purpose Lathes

Special purpose lathes are designed for specific applications, such as glassworking or metal spinning. These lathes are highly specialized and are tailored to meet the unique requirements of their respective industries.

Key Components of a Lathe

Understanding the key components of a lathe is essential for grasping its functionality. These components include:

Bed

The bed is the foundation of a lathe, providing support and stability for the other components. It is made from cast iron to absorb vibrations and maintain precision.

Headstock

The headstock houses the spindle and motors that drive the rotation of the workpiece. It also contains the gear mechanisms that control the speed and torque of the spindle.

Tailstock

The tailstock is located opposite the headstock and can be moved along the bed. It provides additional support for long workpieces and can hold tools for drilling or boring operations.

Carriage

The carriage moves along the bed and holds the cutting tool. It can be moved manually or automatically, depending on the lathe’s design.

Cross Slide

The cross slide is mounted on the carriage and allows for lateral movement of the cutting tool. This enables precise control over the cutting depth and position.

Applications of Lathes in Various Industries

Automotive Industry

Lathes are used to manufacture various components of automobiles, such as engine blocks, crankshafts, and brake discs. Their precision and efficiency make them indispensable in this industry.

Woodworking

Lathes are also widely used in woodworking to create intricate designs and patterns. They are essential for producing furniture, cabinetry, and decorative items.

Metalworking

In metalworking, lathes are used to shape metal parts that are crucial for machinery, construction, and other applications. They are capable of handling a wide range of materials, including steel, aluminum, and brass.

Plastics Manufacturing

The versatility of lathes extends to plastics manufacturing, where they are used to create components for various industries, including consumer electronics, medical devices, and packaging.

Advantages of Using Lathes

The use of lathes offers numerous advantages, including:

Precision and Accuracy

Lathes enable highly precise and accurate machining, resulting in superior quality products. This is particularly important in industries where even the smallest deviations can lead to significant issues.

Versatility

Lathes can perform a wide range of operations, making them incredibly versatile tools. They can handle various materials and produce complex shapes with ease.

Efficiency

Modern lathes are highly automated, reducing the need for manual labor and increasing productivity. This efficiency translates to cost savings and faster production times.

Future Trends in Lathe Technology

The future of lathe technology is promising, with ongoing advancements in automation, materials science, and artificial intelligence. These developments are expected to further enhance the capabilities and efficiency of lathes.

Automation and Robotics

Automation and robotics are poised to play a significant role in the future of lathes. The integration of robotic arms and automated tooling systems will enable even greater precision and efficiency in machining processes.

Advanced Materials

The development of advanced materials with superior properties will open new possibilities for lathe applications. These materials will allow for the creation of stronger, lighter, and more durable components.

Artificial Intelligence

The integration of artificial intelligence in lathe technology will enable smarter, more adaptive machining processes. AI can optimize tool paths, predict maintenance needs, and improve overall machine performance.

Maintaining and Caring for Your Lathe

Proper maintenance is essential for ensuring the longevity and optimal performance of your lathe. Here are some tips for maintaining your lathe:

Regular Cleaning

Keep your lathe clean by regularly removing chips, debris, and coolant residue. This will prevent buildup that can interfere with the machine’s operation.

Lubrication

Ensure that all moving parts are properly lubricated to reduce friction and wear. Use the recommended lubricants and follow the manufacturer’s guidelines.

Inspect Components

Regularly inspect key components, such as the spindle, bearings, and gears, for signs of wear or damage. Replace any worn or damaged parts promptly to prevent further issues.

Safety Considerations When Using Lathes

Safety is paramount when operating a lathe. Here are some important safety considerations:

Wear Protective Gear

Always wear appropriate protective gear, including safety goggles, gloves, and ear protection. This will protect you from flying debris, sharp edges, and loud noises.

Follow Operating Procedures

Adhere to the manufacturer’s operating procedures and guidelines. This will ensure safe and efficient operation of the lathe.

Stay Alert

Remain alert and focused while operating the lathe. Avoid distractions and never leave the machine unattended while it is running.

FAQ

What materials can be machined on a lathe?

Lathes can machine a wide range of materials, including metals (such as steel, aluminum, and brass), wood, and plastics. The choice of material depends on the specific application and the capabilities of the lathe.

What is the difference between a CNC lathe and an engine lathe?

A CNC lathe is controlled by a computer and can perform complex operations with high precision. An engine lathe, on the other hand, is manually operated and is more versatile for general machining tasks.

How do I choose the right lathe for my needs?

Choosing the right lathe depends on various factors, such as the type of materials you will be working with, the complexity of the operations, and the volume of production. Consider your specific requirements and consult with experts if needed.

Summary

Lathes are indispensable tools in the manufacturing and machining industries. From their early history to the cutting-edge technology of modern times, lathes have continually evolved to meet the demands of various applications. Understanding the different types of lathes, their components, and their applications can help you make informed decisions and optimize your machining processes.

Further Reading

For more information on advanced lathe technology and its applications, check out the resources at Mech Mindset.

For a detailed overview of the history and functionality of lathes, visit Ercon Engineering.

Explore how our inspection technologies can enhance your lathe operations: Paint Inspection, Genetic Analysis, Semiconductor Inspection.