In the industrial world, one machine stands out for both its utility and potential hazards: the lathe. This machinery, central to many manufacturing processes, poses significant risks if not operated with utmost caution. Understanding why are lathes so dangerous is crucial for any industry professional committed to upholding safety standards.

The Multifaceted Role of Lathes in Industry

Essential Functions

Lathes are vital in shaping materials. Their primary function involves rotating a workpiece against various tools to achieve desired shapes and sizes. They are pivotal in manufacturing components for automotive, aerospace, and numerous other industries.

Diverse Applications

The versatility of lathes cannot be overstated. From metalworking to woodworking, these machines are integral to creating precise, high-quality products. This widespread applicability underscores their importance and necessitates an understanding of their risks.

Inherent Dangers of Lathe Machines

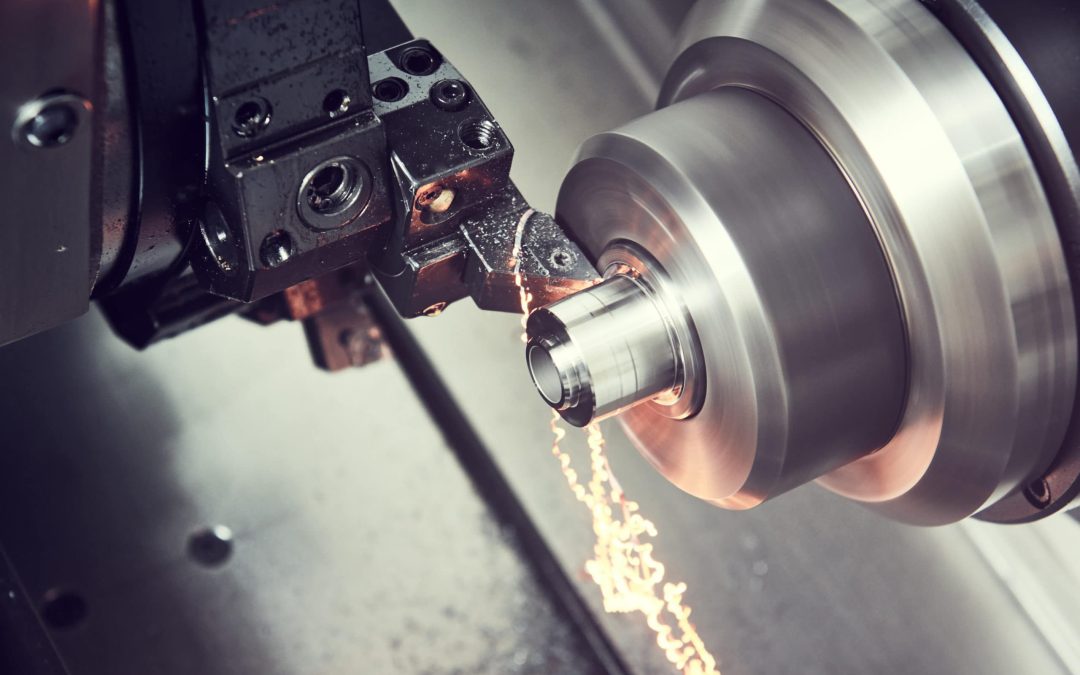

High-speed Rotations

One of the primary reasons why are lathes so dangerous lies in their high-speed operation. The rotational speeds can reach thousands of RPMs, making even minor errors potentially catastrophic.

Sharp Cutting Tools

Lathes employ extremely sharp tools to cut and shape materials. These tools, if mishandled, can cause severe injuries, underscoring the need for stringent safety protocols.

Common Accidents and Their Causes

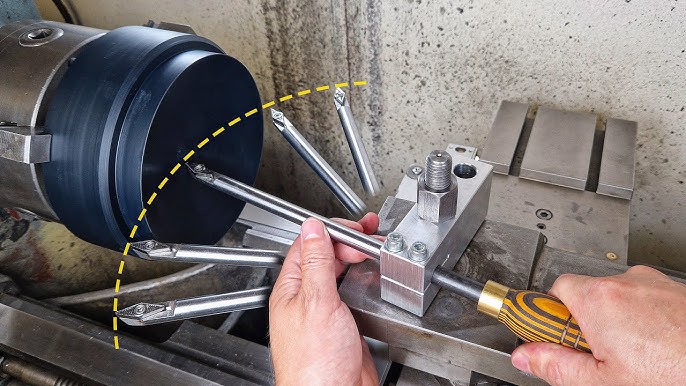

Entanglement Incidents

Clothing, hair, or even fingers can become entangled in the rotating parts of a lathe. Such incidents often result from inadequate safety measures or lapses in attention.

Tool Malfunctions

Improper maintenance or the use of defective tools can lead to malfunctions. When a cutting tool breaks or malfunctions, the resulting projectiles can cause serious harm.

Preventive Measures and Best Practices

Proper Training

Ensuring that operators are well-trained is a fundamental preventive measure. Comprehensive training programs equip individuals with the knowledge to handle lathes safely and effectively.

Regular Maintenance

Routine inspection and maintenance of lathe machines are necessary to identify and rectify potential hazards. Regular upkeep helps prevent mechanical failures that could lead to accidents.

Technological Advancements in Lathe Safety

Safety Features

Modern lathes come equipped with various safety features, including automatic shut-off mechanisms, protective shields, and emergency stop buttons, which significantly reduce the risk of accidents.

Innovative Monitoring Systems

Advanced monitoring systems are now available to oversee lathe operations in real-time, detecting anomalies before they escalate into dangerous situations.

Case Studies Highlighting Lathe Dangers

Industrial Accidents

Numerous case studies document severe accidents involving lathes. These real-world examples illustrate the importance of adhering to safety protocols and regulations.

Lessons Learned

Analyzing past incidents provides valuable lessons that can be applied to enhance safety measures and prevent future accidents.

The Role of Regulations and Standards

Compliance Requirements

Occupational safety regulations mandate specific measures to ensure the safe operation of lathe machines. Compliance with these standards is non-negotiable for maintaining workplace safety.

Continuous Improvement

Industry standards and regulations are continually evolving to incorporate new safety technologies and practices. Staying updated and compliant is critical for all industry professionals.

FAQs

Why are high-speed rotations in lathes dangerous?

High-speed rotations can cause minor errors to become catastrophic, making it essential to handle these machines with care and precision.

What safety features are common in modern lathes?

Modern lathes include safety features such as automatic shut-off mechanisms, protective shields, and emergency stop buttons.

How does regular maintenance contribute to lathe safety?

Regular maintenance helps identify potential hazards, ensuring that the machine operates safely and efficiently.

For more details on the proper use and safety measures of lathes, you can visit this resource.

Also, ensure you check out related articles from our site: event detection, paint inspection, and genetic analysis.