In the modern era of manufacturing, the term ‘CNC lathes’ has become synonymous with efficiency, precision, and technological advancement. But ‘what is CNC lathes’? In this article, we’re delighted to take you through the ins and outs of CNC lathes, exploring their tremendous potential and the reasons why they are so highly approved in the industry.

Understanding CNC Lathes

What Does CNC Stand For?

The acronym CNC stands for Computer Numerical Control. Simply put, it refers to the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands.

The Evolution of Lathes

Lathes have been around for centuries, evolving from simple hand-operated versions to the advanced CNC lathes we know today.

Why Are CNC Lathes a Big Deal?

CNC Lathes have transformed the manufacturing landscape. They offer unparalleled precision and efficiency, making them a terrific addition to any manufacturing process. You can explore more about how these machines are revolutionizing industries in this guide.

Components of CNC Lathes

Main Spindle

The spindle is one of the machine’s fundamental parts. It holds and rotates the raw material (or workpiece).

Control System

The control system is the computer interface where operators input the commands and design files.

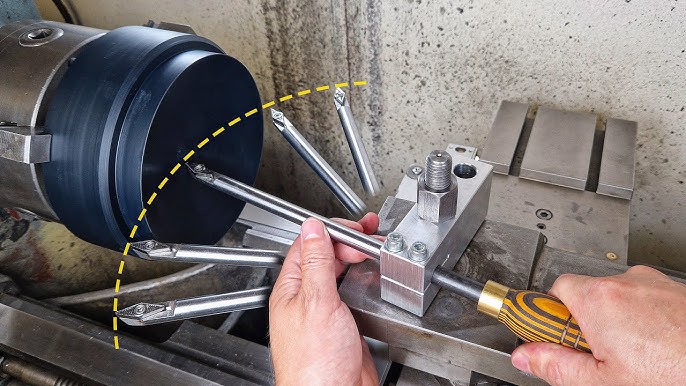

Cutting Tools

Specialized tools that do the actual cutting, shaping, boring, and threading tasks on the material.

Tremendous Technology

The technology behind CNA lathes is designed for both high-speed and high-precision tasks. Learn more about high-speed genetic analysis sequencing monitoring.

Types of CNC Lathes

Horizontal CNC Lathes

These are the most common types and are widely used in various industries.

Vertical CNC Lathes

Typically used for large, heavy workpieces.

Multi-axis CNC Lathes

Great for complex tasks as they can move in multiple axes.

How Do CNC Lathes Work?

CNC Lathes work by following a set of programmed instructions. The operator inputs these instructions into the control system, which then directs the spindle and cutting tools to perform specific tasks on the workpiece.

Applications of CNC Lathes

Automotive Industry

Used for manufacturing parts like gears, shafts, and engine components.

Aerospace Industry

Critical for producing high-precision aircraft components.

Electronics Industry

Often used in creating parts for electronic devices.

Semiconductor Industry

Explore how high-speed semiconductor manufacturing can be improved by using CNC lathes here.

Advantages of CNC Lathes

Precision

One of the key benefits of CNC lathes is their unmatched precision.

Efficiency

These machines can operate 24/7, leading to significant reductions in production time.

Cost-Effectiveness

Although the initial investment is high, the long-term savings make it worthwhile.

Challenges in Using CNC Lathes

High Initial Cost

The upfront cost can be a deterrent for small businesses.

Complexity

Requires skilled operators to manage and maintain the machines.

Future of CNC Lathes

The future of CNC lathes looks very promising with advancements in AI and machine learning.

High-Speed Innovations

Innovations like high-speed paint and coating applications are just the beginning. Discover more here.

FAQ

What materials can CNC lathes work with?

CNC lathes can work with a variety of materials including metals, plastics, and wood.

How accurate are CNC lathes?

They are extremely accurate, often within microns.

Are CNC lathes expensive to maintain?

Maintenance costs are generally low but depend on the machine’s usage and complexity.

Conclusion

To summarize, CNC lathes are a tremendous technological advancement that offers precise, efficient, and cost-effective solutions for various industries. Their potential for shaping the future of manufacturing is immense.