Have you ever wondered how do lathes work? This remarkable piece of technology has transformed industries, driving precision and efficiency to new heights. In today’s article, we will delve deep into the inner workings of lathes and uncover their tremendous impact on modern manufacturing.

Lathe machines have a rich history and are hailed as one of the oldest and most essential tools in the realm of machining. From woodturning to metalworking, lathes play a crucial role in shaping materials into intricate designs with unparalleled accuracy.

What Is a Lathe Machine?

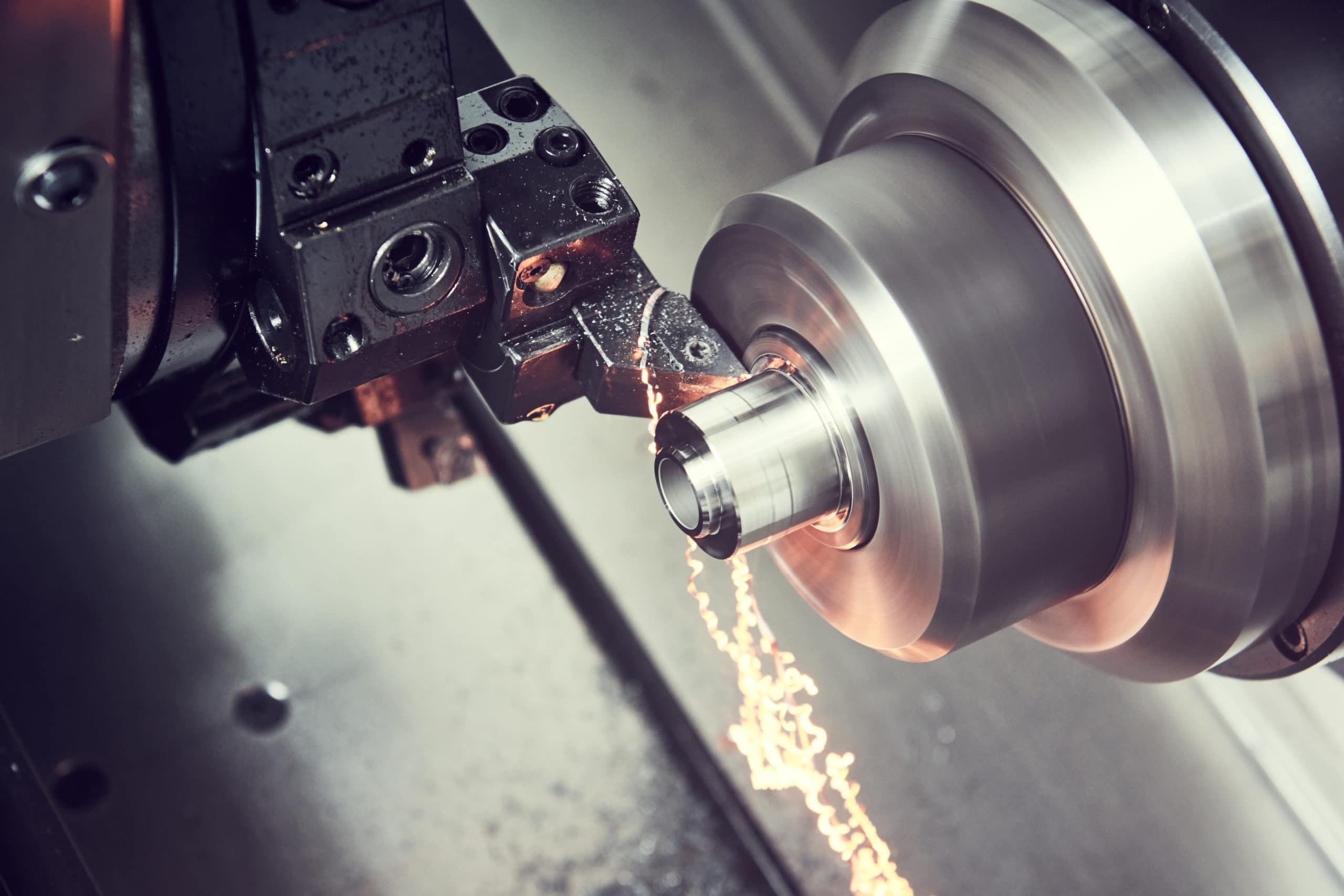

A lathe is a versatile machine tool used primarily to shape metal, wood, and other materials. It operates by rotating the workpiece around a stationary cutting tool, allowing for precision cutting, sanding, drilling, and turning. The end product could be anything from chess pieces to engine components.

A key feature of lathes is their ability to execute a variety of operations by altering the cutting tool and setup. This versatility makes them indispensable in industries spanning from aerospace to fine woodworking.

Components of a Lathe Machine

To understand how do lathes work, it’s essential to get familiar with their primary components, which include:

- Headstock: This houses the drive mechanism and spindle, responsible for holding and rotating the workpiece.

- Tailstock: Positioned opposite the headstock, the tailstock provides support to the workpiece during operations.

- Carriage: Moves the cutting tool along the workpiece for longitudinal cuts.

- Bed: The base of the lathe, providing support and maintaining alignment.

- Feed Mechanism: Allows automated movement of the cutting tool.

How Does a Lathe Work?

The basic principle behind a lathe machine revolves around the rotation of the workpiece. The spindle in the headstock holds and spins the material, while the cutting tool, mounted on the carriage, moves to carve out the desired shape.

This action resembles woodturning, but with far greater precision and the ability to work with various materials. The cutting tool removes small amounts of material with high accuracy, thanks to the lathe’s precise control mechanisms.

Different Types of Lathes

There are several types of lathes, each designed for specific applications:

- Engine Lathes: Traditional and versatile, suitable for general-purpose machining.

- Turret Lathes: Equipped with a turret, allowing multiple cutting operations without manual tool change.

- Tool Room Lathes: Highly precise and used for fine-tuning and complex operations.

- Automatic Lathes: Automated processes for high-volume production.

Applications of Lathe Machines

Lathes have a wide range of applications in industries such as:

- Automotive: Manufacturing of engine components.

- Aerospace: Precision machining of aircraft parts.

- Woodworking: Crafting intricate wood designs.

- Metalworking: Creating detailed metal parts for various machinery.

Importance in Modern Manufacturing

Lathes are the backbone of many manufacturing processes, contributing to the production of high-precision components that meet stringent quality standards. The ability to produce consistent and accurate parts is crucial for industries reliant on precision engineering.

Advantages of Using a Lathe

The benefits of employing a lathe machine in manufacturing are numerous:

- Precision: Lathes offer exceptional accuracy, reducing material waste and ensuring tight tolerances.

- Versatility: The ability to handle different materials and perform various operations.

- Efficiency: Automation capabilities increase production speed and reduce manual labor.

- Consistency: Ensures uniformity in mass production, with minimal risk of defects.

Challenges Faced in Lathe Machining

Despite their advantages, lathes also present challenges, such as:

- Complexity: Requires skilled operators to set up and manage the machine.

- Maintenance: Regular upkeep is needed to maintain precision.

- Safety: Operators must follow stringent safety protocols to avoid accidents.

Future of Lathe Technology

The future of lathe technology is bright with advancements in automation, AI integration, and enhanced precision capabilities. Innovations such as CNC (Computer Numerical Control) have already revolutionized lathe operations, paving the way for more sophisticated and efficient machining processes.

Conclusion: Embracing the Tremendous Impact of Lathe Machines

Understanding how do lathes work allows us to appreciate their pivotal role in modern manufacturing. These machines embody the perfect blend of art and science, shaping our world with unparalleled precision and versatility. As technology continues to evolve, the tremendous impact of lathe machines is poised to grow even further, driving industries to new heights of innovation and efficiency.

To gather more insights about lathes, you can refer to this detailed article.

Also, here are some fascinating reads to help you further understand various manufacturing and inspection methodologies: Coating Inspection, Wafer Polishing, and Genetic Analysis.

Frequently Asked Questions (FAQs)

What materials can be used on a lathe machine?

Lathe machines can work with a wide range of materials including metals, wood, plastics, and composites. Different types of lathes may be optimized for specific materials, so its important to choose the right machine for your needs.

How does a CNC lathe differ from a traditional lathe?

A CNC lathe integrates computer controls for precise, automated machining tasks. While traditional lathes require skilled operators for manual adjustments, CNC lathes offer enhanced accuracy and efficiency through computerized instructions.

What safety measures should be followed when operating a lathe?

Safety is paramount when using a lathe. Operators should wear protective gear, avoid loose clothing, and follow the machine’s safety guidelines. Regular maintenance checks and proper training are also essential to ensure safe operations.