The question of ‘which is the most basic of the manual lathes?’ is often asked by many, especially those new to the world of machining. Understanding the fundamental equipment is crucial for both beginners and seasoned professionals. Manual lathes are essential machines in the manufacturing and tooling industry.

In this article, we aim to provide a deep understanding of the most basic manual lathe, its functionality, and why mastering it is important. Let’s dive into this tremendous technology and see why the basic manual lathe is so important.

Introduction to Manual Lathes

For starters, a manual lathe is a type of lathe that is operated by hand rather than controlled by computer software. It is favored in various industries for its simplicity and control.

Historical Overview

The manual lathe has been around for centuries. Originating in ancient Egypt, it has evolved significantly but remains an essential piece of equipment. It’s big in its impact and utility.

Parts of a Manual Lathe

Understanding the parts of a manual lathe is crucial for anyone looking to use one effectively. Here are the main components:

Bed

The bed is the base of the lathe, providing rigidity and alignment for other parts.

Headstock

The headstock houses the spindle and other driving mechanisms.

Tailstock

The tailstock is used for support, especially when working on longer workpieces.

Carriage

The carriage moves the cutting tool in both the longitudinal and transverse directions.

Types of Manual Lathes

There are various types of manual lathes, including:

Engine Lathe

The most basic and versatile type of manual lathe.

Turret Lathe

Ideal for repetitive production of duplicate parts.

Toolroom Lathe

Used for precision work and high tolerance applications.

Which is the Most Basic of the Manual Lathes?

The Engine Lathe is often considered the most fundamental and basic type of manual lathe. It is the go-to machine for general-purpose work.

Why the Engine Lathe is Fundamental

The engine lathe’s simplicity makes it an excellent starting point for anyone new to machining. It’s straightforward design and versatility make it a staple in many workshops.

Applications of the Engine Lathe

Engine lathes are used in various industries, including automotive, aerospace, and general manufacturing. They are perfect for tasks such as turning, threading, and facing.

Operating a Basic Manual Lathe

Operating a manual lathe requires skill and attention to detail. Here are some basic steps:

Setting Up the Machine

Ensure that the lathe is properly set up and aligned before starting work.

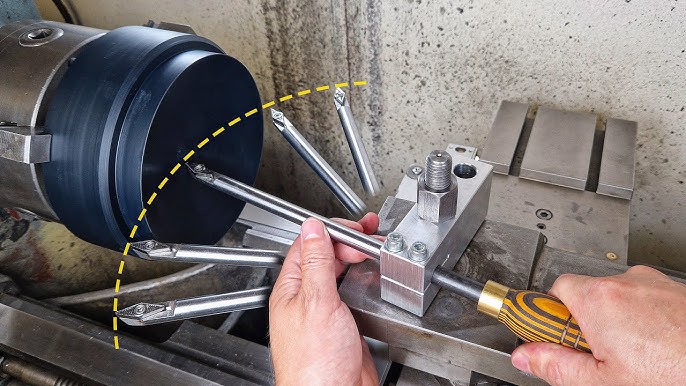

Selecting the Cutting Tool

Choose the appropriate cutting tool for the material and the task.

Setting the Speed

Set the spindle speed according to the material being machined.

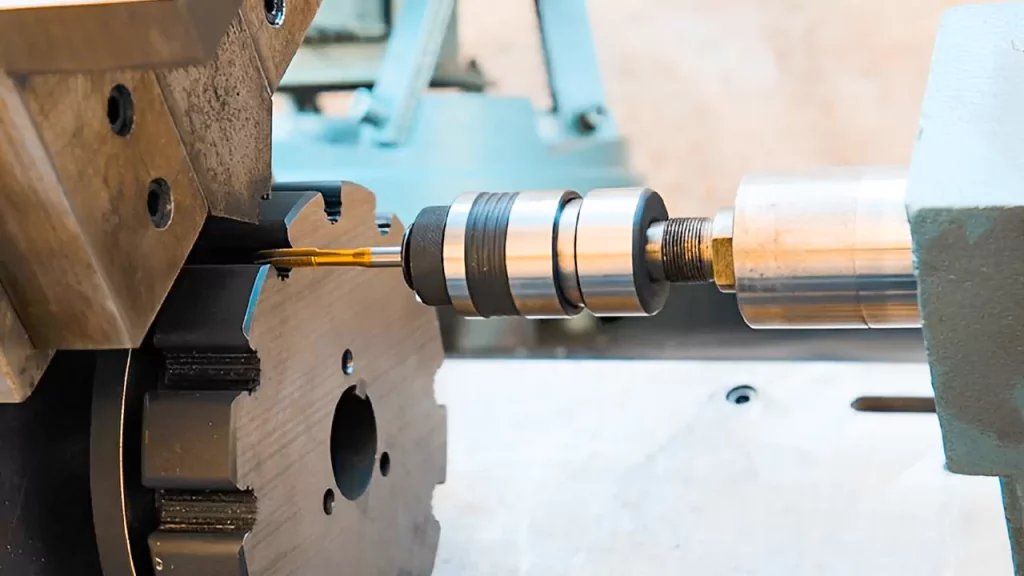

Making the Cut

Carefully engage the cutting tool with the workpiece to make the cut.

Safety Precautions

When operating a manual lathe, safety is paramount. Always wear protective gear and ensure the machine is properly maintained.

Modern Upgrades

While the basic engine lathe remains largely unchanged, modern versions come with various upgrades such as digital readouts and enhanced precision features.

Choosing the Right Manual Lathe

Consider factors such as the type of work, budget, and space when choosing a manual lathe.

Conclusion

Understanding which is the most basic of the manual lathes is crucial for anyone entering the world of machining. The engine lathe’s simplicity and versatility make it an excellent choice for both beginners and experienced professionals. By mastering this fundamental machine, you lay a strong foundation for future machining endeavors. For further reading on advanced lathes, you can refer to this Wikipedia article.

FAQs

What is a manual lathe?

A manual lathe is a machine tool used for shaping metal or wood, operated by hand.

Which manual lathe is best for beginners?

The engine lathe is often recommended for beginners due to its simplicity and versatility.

What safety precautions should I take?

Always wear protective gear, ensure the machine is properly maintained, and follow operating guidelines.