When it comes to precision machining, Sharp lathes stand out as a top choice for professionals and hobbyists alike. But have you ever wondered, where are sharp lathes made? In this article, we will explore the history, production processes, and the modern technology behind these incredible machines.

Introduction to Sharp Lathes

Lathes are essential tools in the machining world. They allow for precise shaping and cutting of materials, making them invaluable in various industries. From automotive to aerospace, lathes play a crucial role. Among the multitude of lathe brands, Sharp has carved a niche for itself with its high-quality and reliable machines.

The History of Sharp Lathes

The story of Sharp lathes begins with a vision of creating superior machining tools. Founded several decades ago, Sharp Industries has grown to become a globally recognized brand. The key to their success lies in their commitment to quality and innovation.

Where Are Sharp Lathes Made?

The manufacturing of Sharp lathes is a global endeavor. While the brand originated in the United States, today, Sharp lathes are manufactured in state-of-the-art facilities around the world. These locations are strategically chosen to ensure the highest standards of quality and efficiency.

Manufacturing Locations

Sharp Industries has multiple production facilities across the globe. In the United States, their primary manufacturing hub is located in Southern California. Additionally, they have facilities in Taiwan and South Korea, where advanced technology and skilled labor come together to produce top-notch lathes.

Production Process of Sharp Lathes

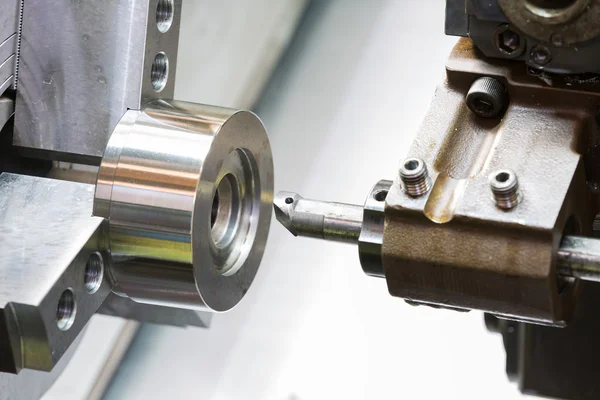

The production of Sharp lathes involves a meticulous process that combines cutting-edge technology with skilled craftsmanship. Each component is carefully crafted and assembled to ensure maximum precision and durability.

Component Sourcing

Sharp Industries sources the finest materials from around the world. This ensures that every lathe is built to withstand the rigors of heavy-duty use. Key components such as the bed, headstock, and tailstock are made from high-grade cast iron, known for its exceptional strength and stability.

Advanced Manufacturing Techniques

The manufacturing process of Sharp lathes incorporates advanced techniques such as CNC machining and robotic automation. These technologies enable precise and efficient production, resulting in lathes that deliver consistent performance.

Quality Control Standards

Quality control is a top priority for Sharp Industries. Each lathe undergoes rigorous testing and inspection to ensure it meets the highest standards. From dimensional accuracy to surface finish, every aspect of the lathe is scrutinized to guarantee top-notch performance.

Inspection and Testing

Sharp lathes undergo a series of inspections and tests during the production process. This includes dimensional checks, spindle calibration, and test cuts. These measures ensure that each lathe operates smoothly and accurately.

Technological Innovations

Sharp Industries continuously invests in research and development to stay at the forefront of technological advancements. This commitment to innovation is reflected in their latest lathe models, which feature advanced capabilities such as digital readouts, programmable logic controllers, and variable speed drives.

Digital Readouts

The incorporation of digital readouts allows for precise measurement and control, enhancing the overall accuracy of the lathe. This feature is particularly beneficial for intricate and complex machining tasks.

Programmable Logic Controllers

Programmable logic controllers (PLCs) enable automation and customization in lathe operations. With PLCs, operators can program specific tasks and sequences, improving efficiency and reducing the margin of error.

Customer Satisfaction and Support

Customer satisfaction is at the core of Sharp Industries’ philosophy. They offer comprehensive support and service to ensure that their customers get the most out of their lathes. This includes technical assistance, training programs, and a robust warranty policy.

Technical Assistance

Sharp Industries provides expert technical assistance to address any issues or concerns that customers may have. Their team of skilled technicians is always ready to help, ensuring minimal downtime and maximum productivity.

Training Programs

To help customers make the most of their Sharp lathes, the company offers extensive training programs. These programs cover everything from basic operation to advanced machining techniques, empowering users with the knowledge and skills needed for optimal performance.

The Future of Sharp Lathes

As technology continues to evolve, so too does the world of machining. Sharp Industries is committed to staying ahead of the curve by continually innovating and improving their lathe models. With a focus on sustainability and efficiency, the future of Sharp lathes looks brighter than ever.

Sustainability Initiatives

Sharp Industries is actively working towards more sustainable manufacturing practices. This includes reducing waste, conserving energy, and using eco-friendly materials. These initiatives not only benefit the environment but also contribute to the overall efficiency and quality of their lathes.

Conclusion

So, where are Sharp lathes made? The answer lies in a combination of global manufacturing prowess and unwavering commitment to quality. From their origins in the United States to their advanced facilities in Taiwan and South Korea, Sharp Industries continues to deliver exceptional lathes that meet the highest standards of performance and reliability.

For more information on lathes, you can visit this comprehensive guide.

FAQs

1. What materials are used in the production of Sharp lathes?

Sharp lathes are made from high-grade materials such as cast iron and steel to ensure durability and precision.

2. Can I get technical support for my Sharp lathe?

Yes, Sharp Industries offers expert technical assistance to help you with any issues or concerns.

3. Are there training programs available for Sharp lathe users?

Yes, Sharp Industries provides training programs to help users get the most out of their lathes.