If you’ve been wondering where Precision Matthews lathes are made, you’re not alone. This question comes up frequently, especially among Industry QA Professionals who value high-quality machining tools. Precision Matthews has become synonymous with tremendous technology and a relentless focus on quality.

What Sets Precision Matthews Apart?

Before diving into the specifics of where these lathes are manufactured, it’s important to understand what makes them stand out. Precision Matthews is delighted to offer top-notch lathes known for their exceptional precision and durability. These qualities are highly sought after in various industries, such as automotive, aerospace, and manufacturing.

The History and Evolution

Founded with a mission to provide high-quality machining tools, Precision Matthews has a rich history. From small beginnings, the company has grown to become a major player in the market, thanks to its commitment to using cutting-edge technology.

Why Quality Matters

For Industry QA Professionals, the quality of machining tools is non-negotiable. Poor-quality tools can lead to inaccuracies, inefficiencies, and increased costs. This is where Precision Matthews excels, offering approved and reliable lathes that meet the high standards required in professional settings.

Manufacturing Locations

So, where are Precision Matthews lathes made? The answer lies in a combination of global collaboration and stringent quality control. The company sources parts from specialized manufacturers worldwide but assembles and tests them mainly in the United States. This ensures a high standard of quality assurance.

Global Sourcing

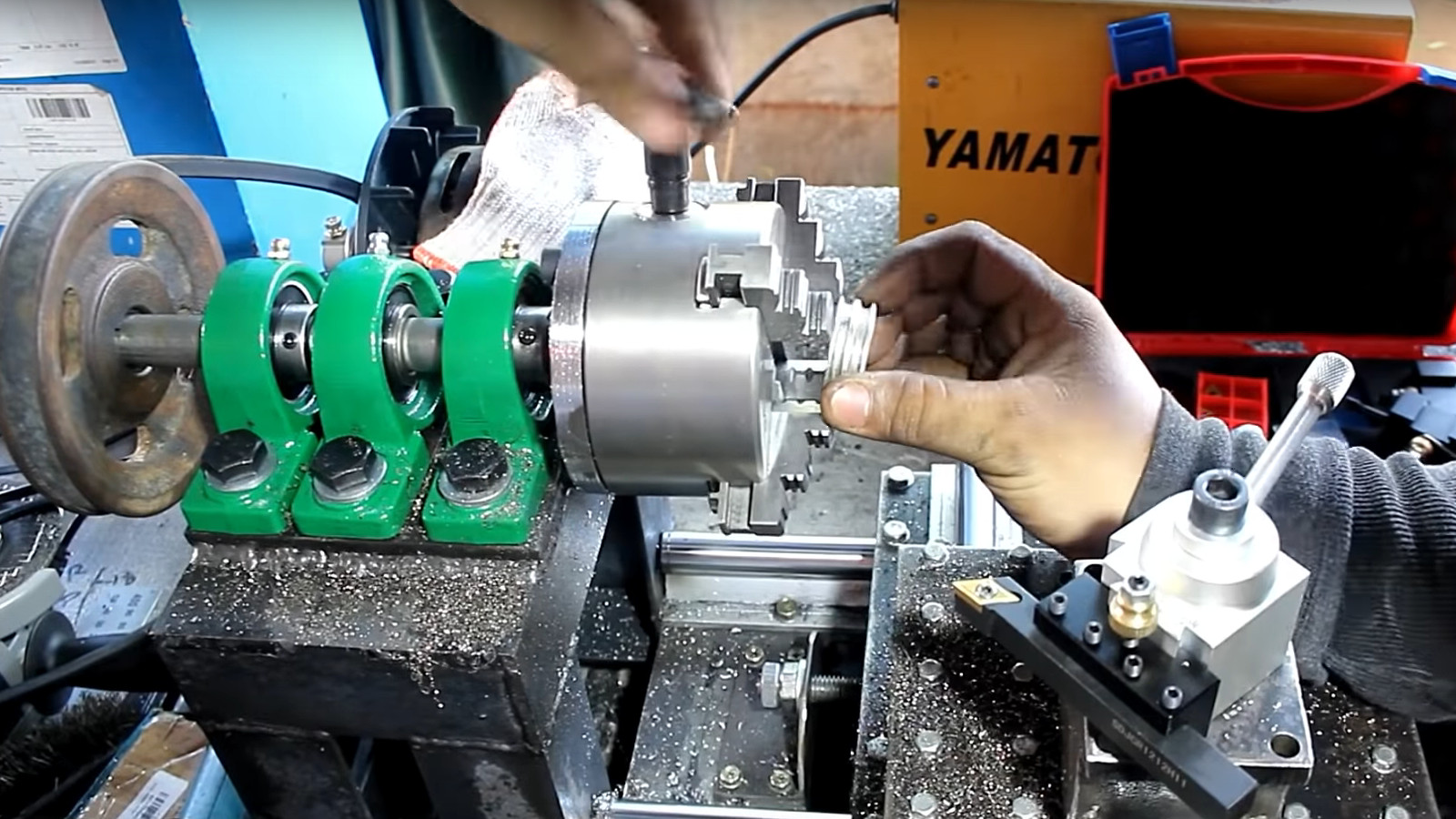

Precision Matthews is known for sourcing the best components globally. From precision bearings to high-grade steel, every part is chosen for its quality and durability. The company works closely with global partners to ensure that every component meets its strict criteria.

Assembly and Testing in the USA

While the components may come from various parts of the world, the assembly and testing processes are primarily conducted in the United States. This allows Precision Matthews to maintain complete control over the quality and performance of their lathes.

Quality Assurance in Manufacturing

Quality assurance is a cornerstone of Precision Matthews’ manufacturing process. Every lathe undergoes rigorous testing to ensure it meets the highest standards. From initial assembly to final inspection, no detail is overlooked.

The Role of Technology

Modern technology plays a significant role in enhancing quality assurance. Precision Matthews employs the latest in automation and robotics to ensure precision in every step of the manufacturing process. This not only increases efficiency but also reduces the margin for error.

Industry Approvals

Precision Matthews lathes are approved by various industry bodies, adding an extra layer of trust and reliability. These approvals are a testament to the company’s commitment to quality and excellence.

Customer Feedback and Reviews

One of the best ways to gauge the quality of a product is through customer feedback. Precision Matthews has received terrific reviews from industry professionals and hobbyists alike. Customers consistently highlight the lathes’ durability, precision, and ease of use.

Case Studies

Several case studies demonstrate the effectiveness of Precision Matthews lathes in real-world applications. For example, a leading aerospace manufacturer reported increased productivity and reduced downtime after switching to Precision Matthews lathes.

Testimonials

Here are some testimonials from satisfied customers:

- ‘These lathes have transformed our production line. The precision is unparalleled.’

- ‘We’ve seen a significant reduction in waste and rework since using Precision Matthews.’

Comparing Precision Matthews with Competitors

When it comes to choosing a lathe, many professionals compare Precision Matthews with other brands. So, how do they stack up? In terms of quality, performance, and price, Precision Matthews often comes out on top.

Quality

The quality of Precision Matthews lathes is often cited as a key differentiator. The combination of global sourcing and USA-based assembly ensures a high standard that is hard to beat.

Performance

In terms of performance, Precision Matthews lathes are known for their reliability and precision. Many users report fewer issues and higher accuracy compared to other brands.

Price

While Precision Matthews lathes may come at a premium, the investment is often justified by the long-term savings in reduced maintenance and increased efficiency.

Maintenance and Support

One of the standout features of Precision Matthews is its superb customer support. The company offers comprehensive maintenance services to ensure your lathe remains in top condition.

Preventive Maintenance

Regular maintenance is crucial for the longevity of any machine. Precision Matthews offers preventive maintenance packages that help you avoid costly breakdowns.

Technical Support

Should you encounter any issues, Precision Matthews’ technical support team is readily available to assist. Their experts can guide you through troubleshooting steps or arrange for repairs if needed.

Future Developments

Looking to the future, Precision Matthews is committed to continuous improvement. The company is investing heavily in R&D to bring even more advanced features to their lathes.

Upcoming Innovations

Some of the upcoming innovations include more automation features and enhanced precision controls. These developments aim to keep Precision Matthews at the forefront of the industry.

Environmental Responsibility

In addition to technological advancements, Precision Matthews is also focusing on sustainability. The company is committed to reducing its environmental impact through various initiatives.

Conclusion

In conclusion, where Precision Matthews lathes are made is a testament to the company’s commitment to quality and excellence. From global sourcing of high-quality components to USA-based assembly and testing, every step is meticulously executed to ensure the best possible product.

For more information about lathe machines, you can visit this detailed guide.

FAQs

Are Precision Matthews lathes reliable?

Yes, they are highly reliable and have received terrific reviews for their durability and precision.

Where are the components sourced from?

The components are sourced globally but assembled and tested in the USA to ensure high quality.

What industries use Precision Matthews lathes?

They are used in various industries, including automotive, aerospace, and manufacturing.

For more insights, check out this page on basic lathes.

For related topics, explore our articles on manufacturing inspection and paint and coating application inspection.