The pursuit of high-quality industrial equipment often leads to the question, ‘Where are Bolton lathes made?’ For industry QA professionals, this is a vital question that ensures their machinery meets rigorous standards. In this article, we will delve deep into the origins, production processes, and the unique aspects of Bolton lathes.

Bolton Tools have established a significant reputation in the industrial equipment market. Their lathes are sought after for their superior quality, precision, and durability. But where exactly are these products manufactured?

The History of Bolton Lathes

Origins and Early Development

Bolton Tools was founded in 1999 and has grown into one of the foremost suppliers of industrial tools and equipment. From the beginning, they focused on importing high-quality machine tools and developing a name synonymous with reliability and precision in the industrial sector.

Brand Evolution

Through years of hard work and diligence, Bolton Tools have refined their processes and expanded their product line. They have continuously adapted to technological advancements, finding ways to improve their machinery’s efficiency and accuracy.

‘Why Quality Matters in Production Locations’

Global Manufacturing Standards

Understanding ‘where Bolton lathes are made’ involves comprehending the global manufacturing standards and quality controls in place. Since introducing ISO certification, Bolton Tools have aligned their production processes with international quality benchmarks.

Material Selection

The meticulous selection of materials is fundamental to the durability and performance of Bolton lathes. They employ high-quality steel sourced globally to ensure every lathe stands up to industrial demands.

The Main Manufacturing Base of Bolton Lathes

Bolton Lathes Production in China

While Bolton Tools is headquartered in the United States, most of their lathe production occurs in China. The country offers a blend of advanced manufacturing capabilities and cost efficiencies, enabling Bolton Tools to provide high-quality products at competitive prices.

Quality Control in Chinese Manufacturing

Chinese manufacturing plants adhere to strict quality control measures. The factories Bolton Tools partner with are regularly audited to ensure they meet international production standards, ensuring an exceptional end product for customers worldwide.

Impact of Technological Advancements

Integration of Modern Technology

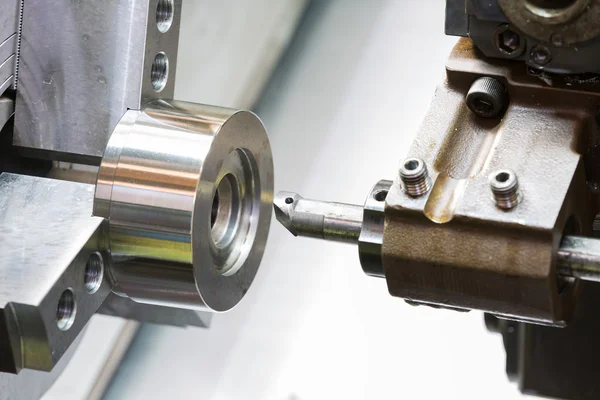

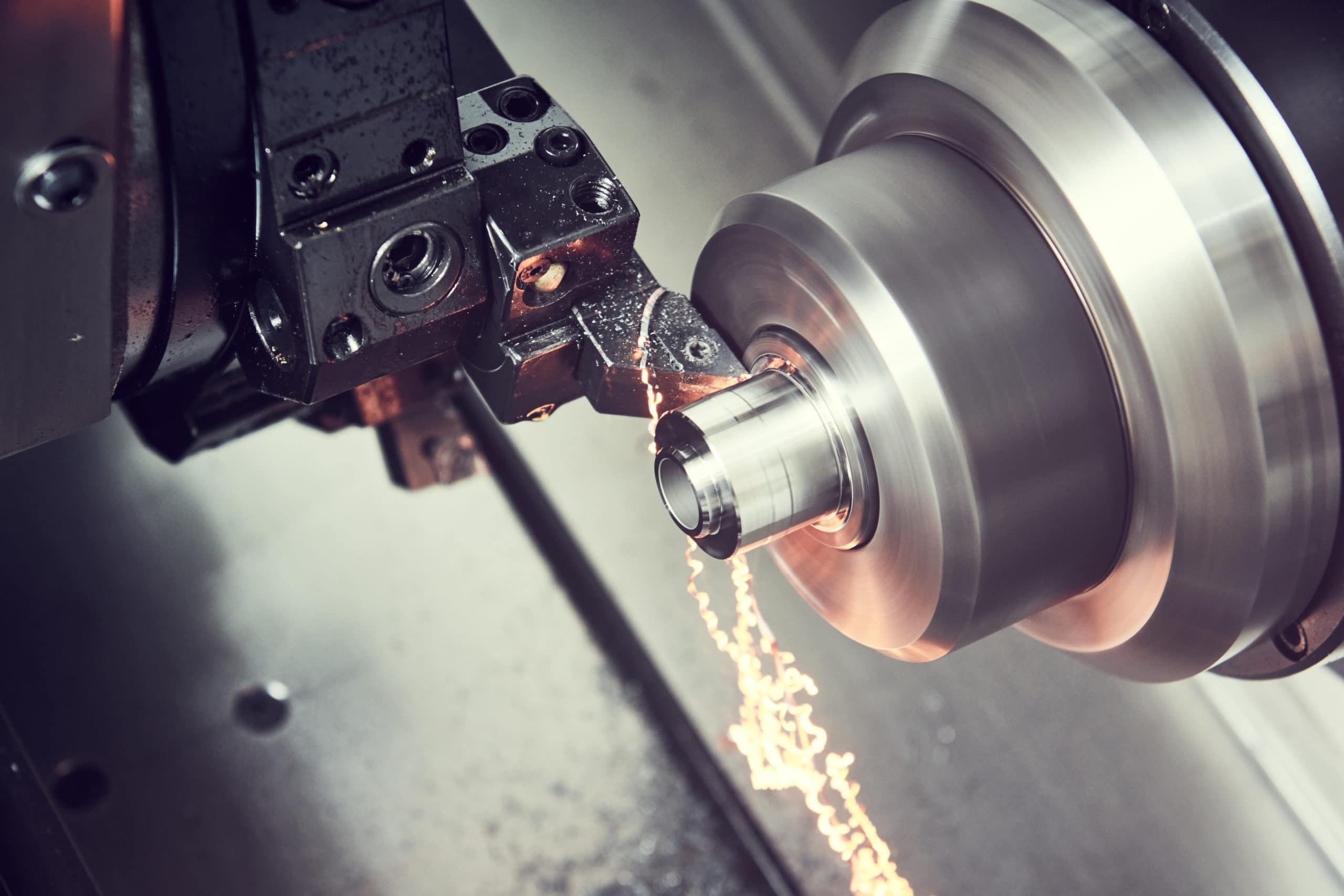

Modern technology has played a crucial role in the evolution of Bolton lathes. With advancements in automation and computer numerical control (CNC), these lathes have become more precise and user-friendly. This allows for intricate designs and applications in various industries.

Continuous Innovation

Bolton Tools isn’t just satisfied with maintaining their current standards; they are always seeking ways to innovate. They invest heavily in research and development to ensure their lathes incorporate the latest technological advancements.

The Benefits of Choosing Bolton Lathes

Durability and Reliability

One of the standout features of Bolton lathes is their durability. Made from high-quality materials and subjected to rigorous quality control processes, these lathes are built to last. They withstand the demands of various industrial applications, making them a reliable choice for professionals.

User-Friendly Design

Another benefit is the user-friendly design. Bolton lathes are crafted with the end-user in mind, ensuring they are easy to use without sacrificing functionality. This is particularly important for industry QA professionals who need to perform precision work efficiently.

Understanding the Cost-Benefit Analysis

Affordable Excellence

When considering ‘where Bolton lathes are made,’ it’s essential to perform a cost-benefit analysis. Bolton Tools have managed to strike a balance between affordability and excellence in quality. Despite being manufactured in China, the stringent quality control measures ensure that these lathes are top-notch.

Long-Term Cost Savings

While the initial investment in a Bolton lathe might be higher than other brands, the long-term cost savings are significant. The durability and minimal maintenance requirements of these lathes reduce long-term operational costs, making them a wise investment.

How Bolton Lathes Compare to Competitors

Competitive Edge

Bolton lathes boast several features that give them a competitive edge. Their blend of advanced technology, user-friendly design, and robust construction puts them ahead of many competitors in the market.

Customer Reviews

Positive feedback from customers further bolsters their reputation. Many industry professionals highlight the exceptional performance and reliability of Bolton lathes, emphasizing their value in various applications.

The Future of Bolton Lathe Production

Expansion Plans

Looking ahead, Bolton Tools has ambitious expansion plans. They aim to further enhance their manufacturing capabilities by investing in new plants and technologies. This commitment to growth ensures they remain at the forefront of the industry.

Sustainability Initiatives

Bolton Tools is also committed to sustainable manufacturing practices. They are actively working to reduce their carbon footprint by implementing eco-friendly processes and sourcing materials responsibly. This aligns with the growing demand for environmentally-conscious products in the industrial sector.

Conclusion

In conclusion, understanding ‘where Bolton lathes are made’ enhances our appreciation for the quality and precision of these remarkable machines. With a strong production base in China, stringent quality control measures, and a commitment to innovation, Bolton Tools continues to set industry standards. For industry QA professionals, investing in a Bolton lathe is not just a purchase; it’s a strategic decision ensuring top-notch performance and reliability.

FAQs

Are Bolton lathes made exclusively in China?

While most Bolton lathes are manufactured in China, Bolton Tools operates globally. They ensure that their production processes in China comply with international standards.

What makes Bolton lathes stand out from other brands?

Bolton lathes are known for their durability, precision, and user-friendly design. The integration of modern technology and rigorous quality controls also set them apart from competitors.

How does Bolton Tools ensure the quality of their lathes?

Bolton Tools implement strict quality control measures in their manufacturing processes. This includes regular audits of their production facilities and adherence to international standards.