A question frequently asked in various manufacturing sectors is: what is a milling machine used for? A milling machine is a versatile tool that finds multiple uses across various industries. From crafting intricate components to large machinery parts, milling machines have proved their tremendous value over the years.

Understanding Milling Machines

Milling machines are designed to carve, drill, and shape solid materials like metal, wood, and plastic. But why are these machines so special and what makes them such an essential tool in modern industries?

Types of Milling Machines

Let’s explore the different types of milling machines:

- Vertical Milling Machines: These machines have a vertically oriented spindle, which holds the cutting tool and moves up and down.

- Horizontal Milling Machines: In these machines, the spindle is horizontally oriented, which allows for horizontal cuts.

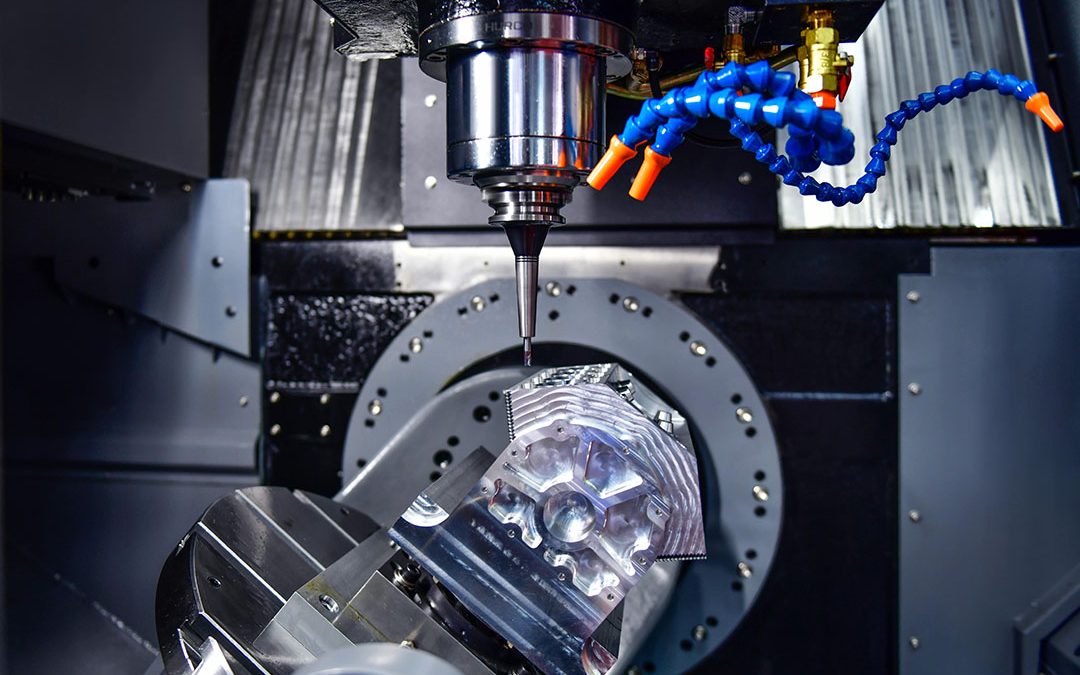

- CNC Milling Machines: These are computer-controlled milling machines that bring a significant level of precision and automation to the milling process.

Main Uses of Milling Machines

Milling machines are used in a variety of industries for numerous applications. Here are some of the primary uses:

Manufacturing of Parts

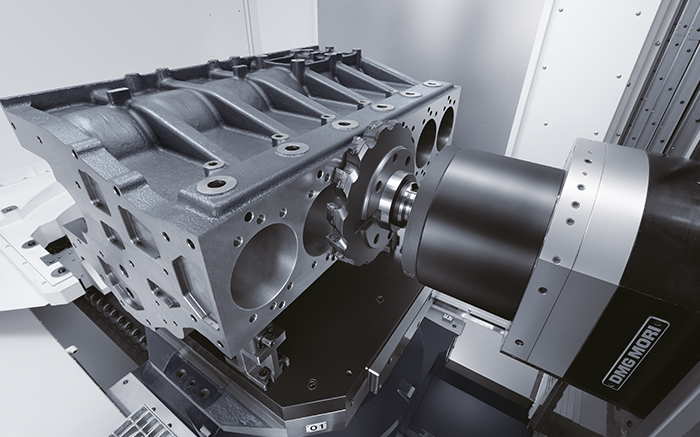

One of the fundamental uses of milling machines is in the manufacturing of parts. Whether it’s for automotive, aerospace, or electronic components, these machines provide the precision and capabilities needed to produce intricate designs.

Prototyping

Milling machines are also used for prototyping. Engineers and designers use them to create prototypes of new products quickly, which helps in evaluating and testing designs before mass production.

Key Components of a Milling Machine

Milling machines consist of several essential components:

- Spindle: Holds the cutting tool and rotates it.

- Table: Supports the workpiece that needs to be milled.

- Knee: This component supports the table and allows vertical movement.

- Overarm/Arbor Support: Provides support for the cutting tool during operations.

Advantages of Using Milling Machines

Milling machines offer a range of benefits:

Precision and Accuracy

These machines provide high precision and accuracy, which are crucial for producing parts that meet strict tolerances and specifications.

Versatility

The versatility of milling machines enables them to perform various operations, such as drilling, cutting, and shaping, all with a single machine.

Efficiency

Milling machines enhance efficiency by automating tasks which would otherwise be performed manually. This boosts productivity and reduces production times significantly.

Applications in Various Industries

Milling machines are utilized in numerous industries:

Automotive Industry

In the automotive industry, milling machines are used to manufacture engine components, gearboxes, and other critical parts.

Aerospace Industry

High precision is crucial in the aerospace industry. Milling machines are used to create complex parts for aircraft and spacecraft.

Electronics Industry

In the electronics industry, these machines produce precise components for various devices, such as circuit boards and connectors.

Challenges and Solutions

Operating milling machines can come with challenges, including ensuring high precision and tool wear. However, many of these challenges can be mitigated through regular maintenance and using high-quality cutting tools.

Future of Milling Machine Technology

Milling machine technology is constantly evolving. Innovations like AI integration and advanced CNC systems promise to make these machines even more efficient and reliable in the future.

Conclusion

In conclusion, milling machines play a crucial role in modern manufacturing by offering versatility, precision, and efficiency. Their applications across various industries make them indispensable tools for creating high-quality products.

FAQs

What industries use milling machines?

Milling machines are used in industries like automotive, aerospace, and electronics, among others.

What are the main types of milling machines?

The main types are vertical, horizontal, and CNC milling machines.

What are the benefits of using a milling machine?

Milling machines offer precision, versatility, and efficiency in manufacturing processes.

For more detailed information on milling machines, you can visit this external resource.

Check out our articles on high-speed genetic analysis, semiconductor manufacturing inspection, and basic manual lathes.