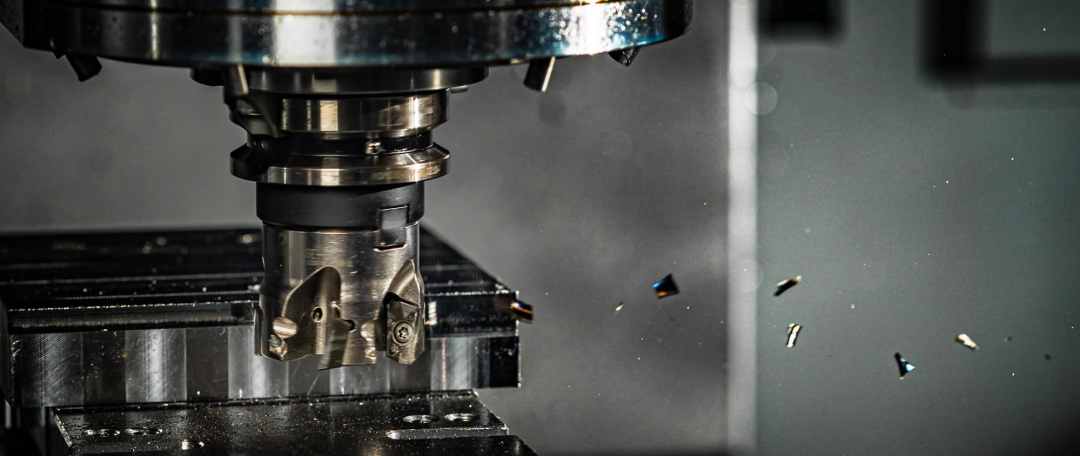

In modern manufacturing, the relevance of a Digital Readout system (DRO) cannot be overstated, especially when attached to a milling machine. For industry QA professionals and manufacturing enthusiasts alike, understanding what is a DRO on a milling machine and its great benefits is crucial. As technology advances, the adoption of DROs on milling machines has become notably significant in achieving high precision and efficiency.

This article explores all aspects of a DRO in detail, shedding light on the technology behind it, its applications, and how it enhances the milling process in various industries.

What is a DRO on a Milling Machine?

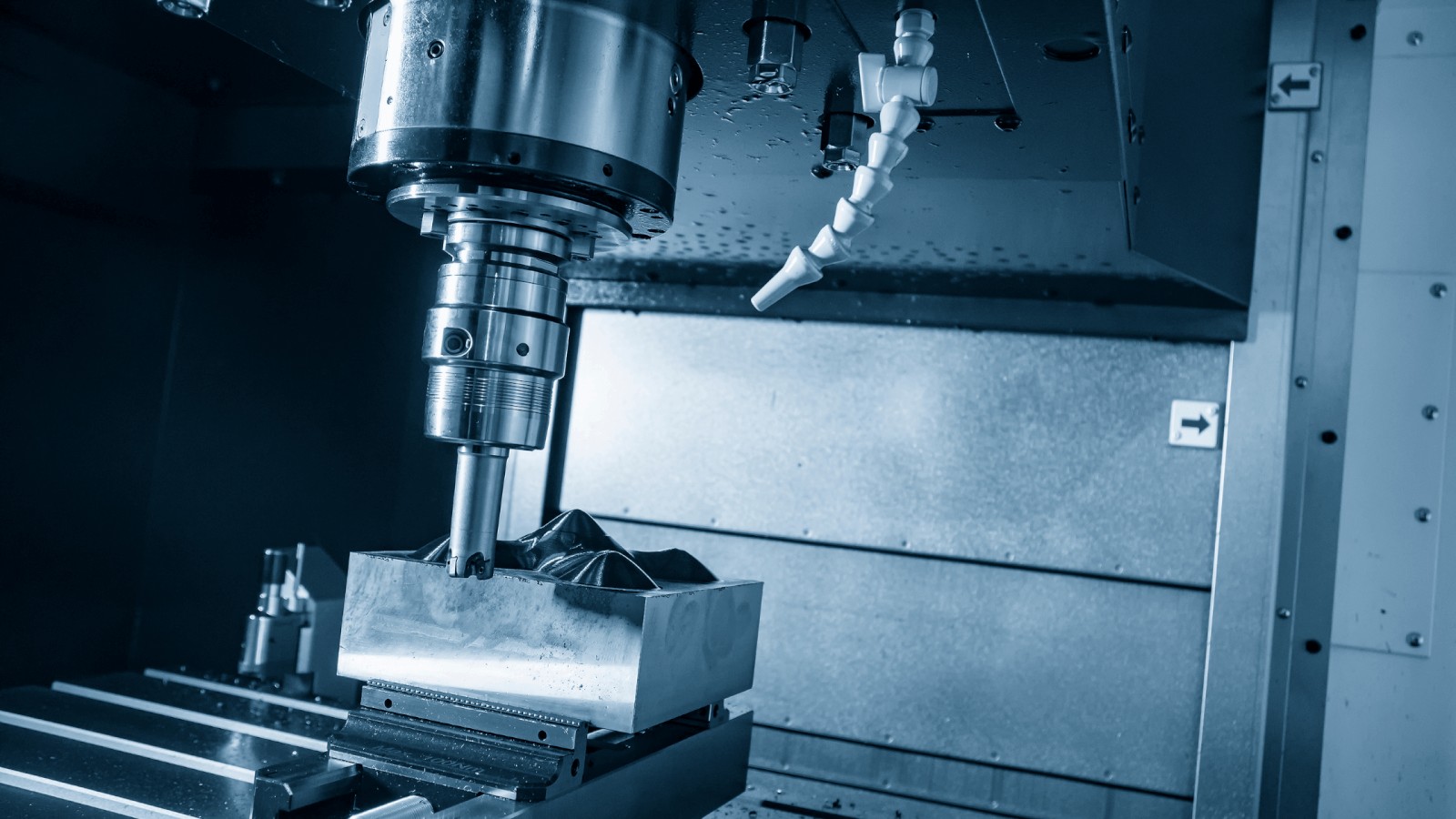

A Digital Readout system (DRO) is an essential component of modern milling machines. It provides precise and real-time readings of the position of the tool and the workpiece, ensuring high accuracy in machining processes. The DRO system consists of a display unit and linear scales mounted on the machine’s axes.

The Importance of DRO in Milling Machines

The primary function of a DRO is to enhance the precision and efficiency of the milling process. Traditional milling machines rely heavily on manual measurements, leading to potential human errors. A DRO eliminates this risk and offers a user-friendly interface for operators to work with, resulting in higher productivity and reduced waste.

Components of a DRO System

Display Unit

The display unit is the central part of the DRO system where the readings are shown. It typically includes a digital screen, functional keys, and other features to enhance usability.

Linear Scales

Linear scales are mounted on the machine’s axes and measure the position of the tool and the workpiece. These scales come in various forms, such as magnetic, glass, and optical, each with its own advantages.

How Does a DRO System Work?

The DRO system works by using the linear scales to measure the movement of the milling machine’s axes. The scales send signals to the display unit, which then translates these signals into precise numeric values that the operator can read easily.

Step-by-Step Working Mechanism

- Measurement: The linear scales measure the movement of the machine’s axes.

- Signal Transmission: The scales send electronic signals to the display unit.

- Reading Display: The display unit processes these signals and shows the exact position of the tool and the workpiece.

Applications of DRO in Milling Machines

DRO systems are widely used in various manufacturing industries due to their ability to enhance precision and efficiency. Some common applications include:

- Automotive industry for producing engine components.

- Aerospace industry for manufacturing aircraft parts.

- Electronics industry for creating precise circuit boards.

Benefits of Using a DRO System

The adoption of DRO systems in milling machines provides numerous benefits, such as:

- Higher accuracy and precision in machining.

- Reduced human errors and waste.

- Enhanced productivity and efficiency.

- User-friendly interface for operators.

Choosing the Right DRO System

When selecting a DRO system for your milling machine, it’s important to consider factors like compatibility, ease of use, and the type of linear scales used. Consulting with an expert or a trusted supplier can help you make an informed decision.

Factors to Consider

- Compatibility with your milling machine.

- Type of linear scales used (magnetic, glass, or optical).

- User interface and display features.

- Cost and warranty.

The Future of DRO Systems

As technology continues to evolve, we can expect to see further advancements in DRO systems. These advancements will likely lead to even greater precision and efficiency in milling processes, making DRO systems an indispensable tool in modern manufacturing.

Frequently Asked Questions

What is a DRO on a milling machine?

A Digital Readout system (DRO) is a crucial part of modern milling machines, providing real-time readings of the tool and workpiece positions for high precision and efficiency.

How does a DRO system enhance precision?

The DRO system eliminates manual measurement errors by providing accurate and real-time position readings, leading to higher precision in machining.

What are the components of a DRO system?

A DRO system consists of a display unit and linear scales mounted on the machine’s axes, which work together to provide precise position readings.

Conclusion

Understanding what is a DRO on a milling machine is essential for anyone involved in modern manufacturing. This technology has revolutionized the milling process, providing tremendous benefits in terms of accuracy, efficiency, and ease of use. With continuous advancements, the future of DRO systems looks promising, making them a valuable asset in the manufacturing industry.

To learn more about milling machines and their components, you can visit this detailed guide.