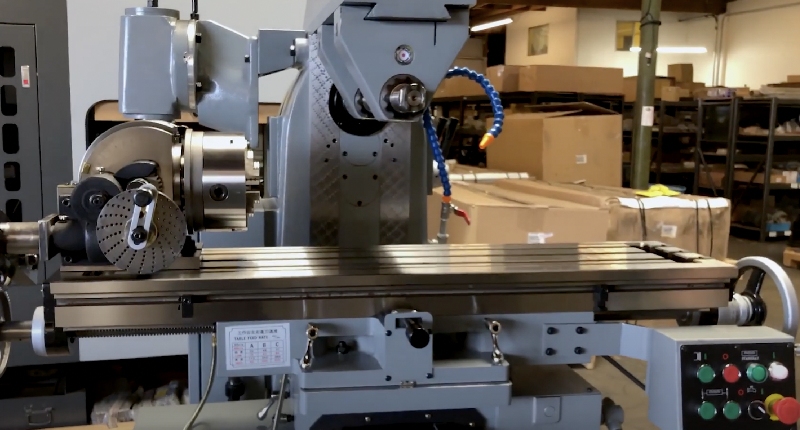

The world of machining tools is vast and complex, encompassing an array of equipment designed to shape and customize various materials. One of the most significant tools in this domain is the knee milling machine. In this article, we’ll explore what a knee milling machine is, its features, and its tremendous applications across different industries.

What is a Knee Milling Machine?

A knee milling machine is a type of machine tool used to precisely cut and shape materials, typically metals and plastics. The unique aspect of this machine is its knee, a vertically adjustable platform that supports the worktable. The knee can be lowered or raised to adjust the depth of the cut, making it highly versatile for various machining tasks.

Components and Structure

The Base

The base of a knee milling machine provides the needed stability. It’s typically made from cast iron, ensuring the machine is sturdy and durable.

The Column

The column is a vertical component that supports the spindle, motor, and other parts. It’s also usually made from cast iron for strength and durability.

The Knee

The knee is the defining feature of this machine, supporting the worktable and the saddle. It can be moved vertically, allowing for precise adjustments during milling operations.

The Worktable

The worktable is where the material to be milled is placed. It can move horizontally in the X and Y axes, making it easy to position the material accurately.

The Spindle

The spindle holds the cutting tool and rotates at various speeds. It can move vertically in the Z axis, allowing for different types of cuts.

Types of Knee Milling Machines

Vertical Knee Milling Machines

In a vertical knee milling machine, the spindle is oriented vertically. This type is commonly used for various precision machining tasks.

Horizontal Knee Milling Machines

In a horizontal knee milling machine, the spindle is oriented horizontally. These machines are generally used for heavy-duty tasks that require extensive material removal.

Applications of Knee Milling Machines

Knee milling machines are used in a wide array of industries, from automotive to aerospace, due to their precision and versatility. They are invaluable for creating intricate parts and components.

The Role of Technology in Modern Knee Milling Machines

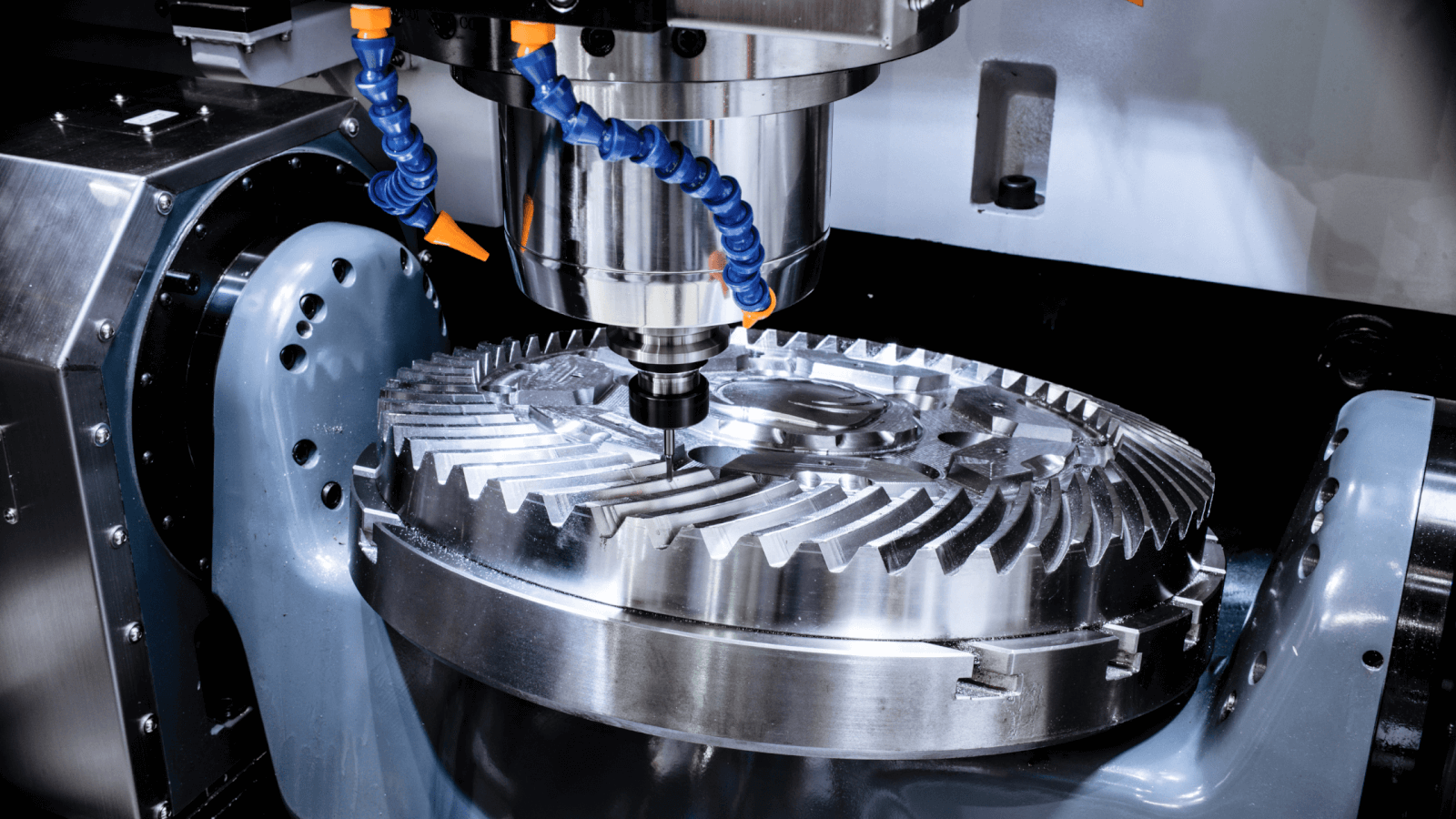

The advent of CNC (Computer Numerically Controlled) technology has revolutionized knee milling machines. CNC allows for automated control, significantly improving precision and efficiency. For more on CNC technology’s advantages over manual methods, check out this article.

Maintenance and Troubleshooting

Proper maintenance is crucial for the effective operation of knee milling machines. Regularly checking the machine parts, ensuring lubrication, and conducting timely repairs are necessary steps for maintaining optimal performance.

Buying Guide: How to Choose the Right Knee Milling Machine

Choosing the right machine requires understanding your specific needs, budget, and the materials you’ll be working with. Evaluating the machine’s power, speed, and additional features can help make an informed decision.

Safety Precautions

Working with knee milling machines involves certain risks. Always wear appropriate safety gear, follow operational guidelines, and conduct regular safety checks to avoid accidents.

Conclusion

In summary, the knee milling machine is a crucial tool in the machining industry, known for its versatility and precision. Understanding its components, types, and applications can significantly enhance your machining projects.

FAQ

What is the main difference between vertical and horizontal knee milling machines?

The main difference lies in the spindle orientation and the types of tasks they are best suited for. Vertical machines have a vertically oriented spindle, ideal for precision tasks, while horizontal machines have a horizontally oriented spindle, suited for heavy-duty tasks.

Is CNC technology applicable to knee milling machines?

Yes, CNC technology can be integrated into knee milling machines, offering automated control, enhanced precision, and efficiency.

How do you maintain a knee milling machine?

Regular maintenance involves checking and lubricating machine parts, ensuring cleanliness, and performing timely repairs to prevent breakdowns.