**Vertical milling machines** are a cornerstone in industrial fabrication and machining. This article will delve into what these powerful machines are used for, how they contribute to various industries, and the tremendous advantages they offer.

Introduction to Vertical Milling Machines

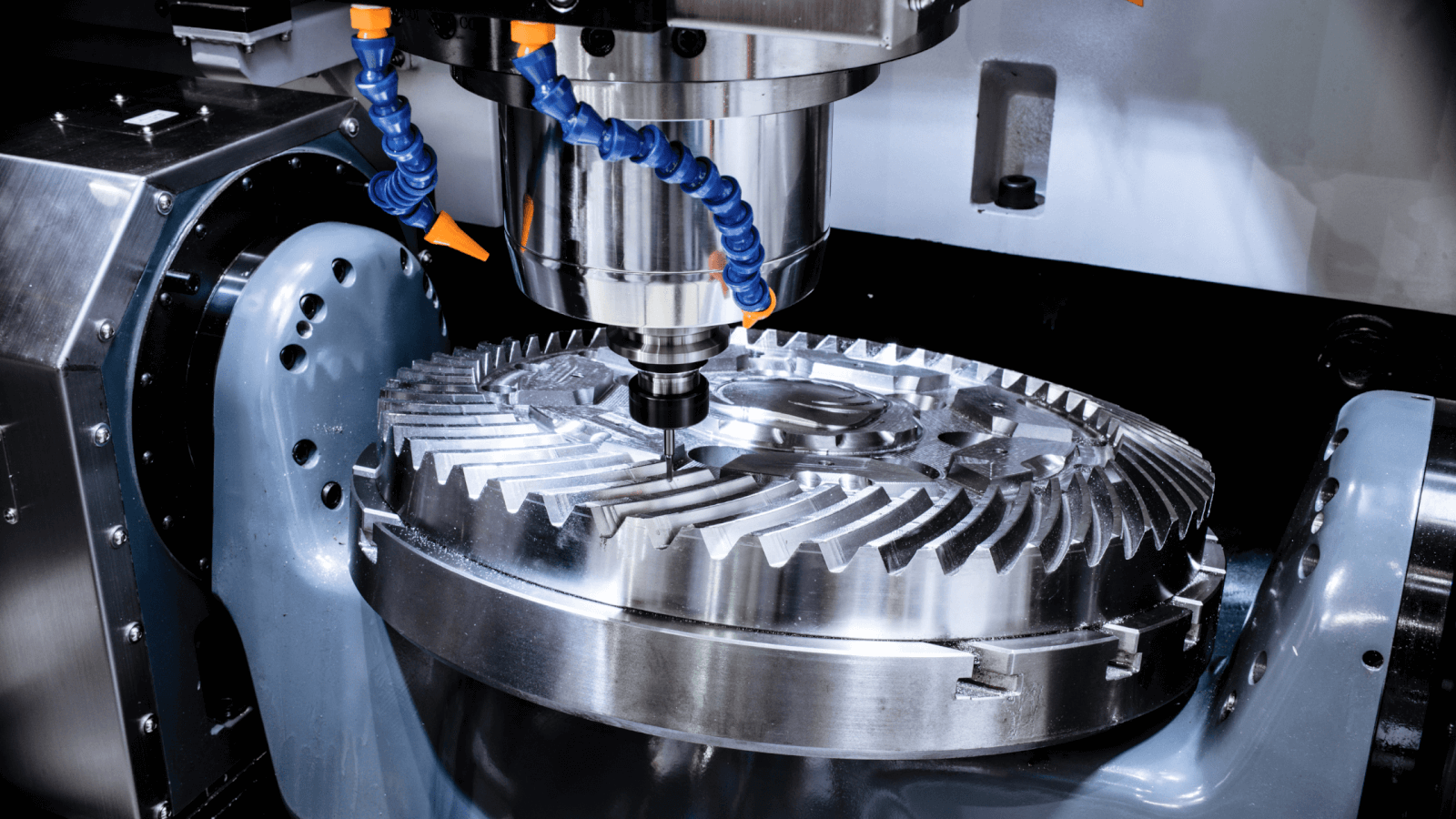

A vertical milling machine is a versatile tool for precision machining that involves the use of rotating cutters to remove material. These machines stand out due to their vertical orientation, meaning the spindle holding the cutting tool is oriented vertically.

Key Components of Vertical Milling Machines

Spindle

The spindle, an integral part of a vertical milling machine, is where the cutting tool is mounted. The spindle’s position allows for a variety of cutting operations.

Worktable

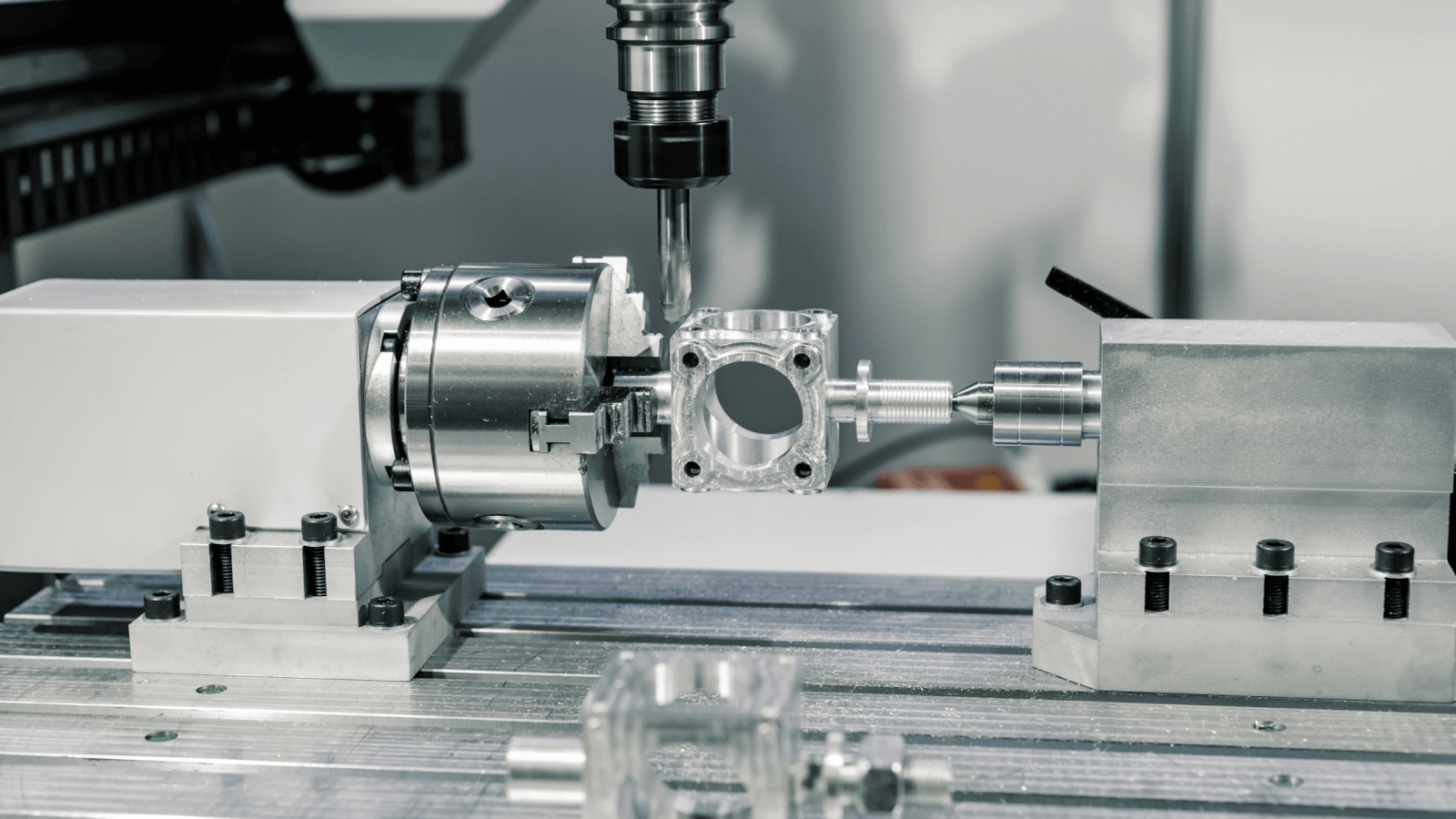

The worktable is where the workpiece is secured. It moves along the X and Y axes to allow precise positioning.

How Do Vertical Milling Machines Work?

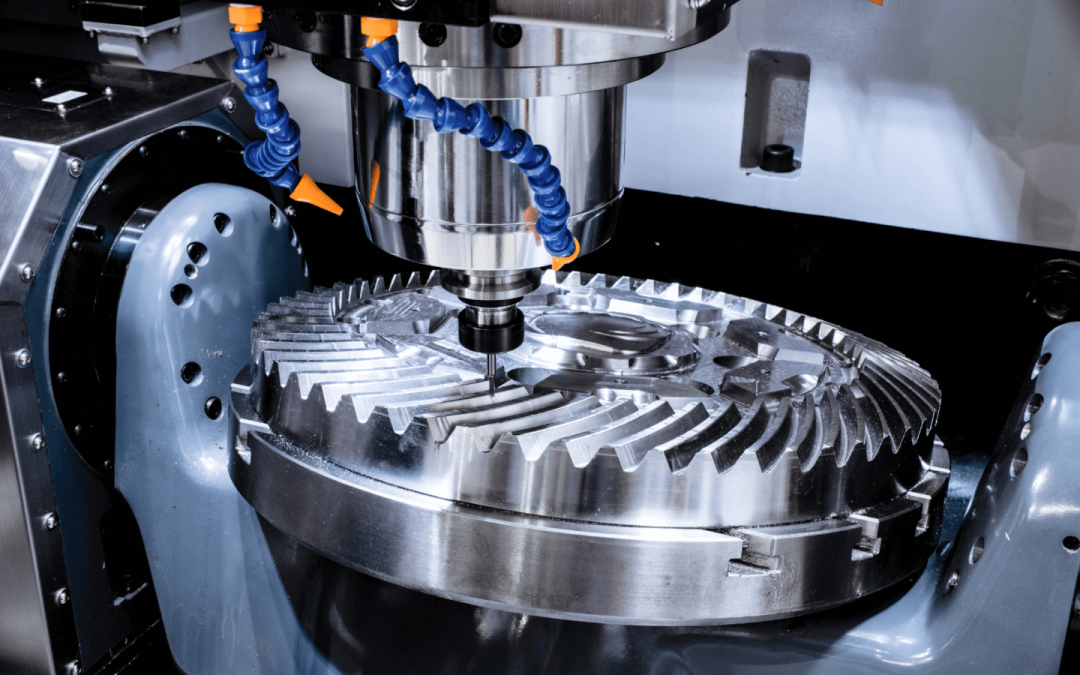

In a **vertical milling machine**, the spindle stays stationary while the worktable moves. The rotating cutting tool removes material from the workpiece, allowing for intricate shapes and precise cuts.

Uses of Vertical Milling Machines

Metal Fabrication

Vertical milling machines are extensively used in **metal fabrication** industries. They can handle tasks ranging from simple drilling to complex contouring.

Mold Making

Mold making is another significant application. The precision offered by vertical milling machines is instrumental in crafting accurate molds for various industries.

Prototype Production

**Vertical milling machines** are crucial during the prototyping phase in product development. Their accuracy and versatility make them indispensable for creating prototypes quickly and effectively.

Advantages of Using Vertical Milling Machines

There are several advantages to using **vertical milling machines**, including:

- High precision

- Versatility

- Ease of operation

- Affordable maintenance

Types of Vertical Milling Machines

Knee-Type

This is the most common type, known for its adjustable construction and flexibility for various task requirements.

Bend-Type

The bend-type vertical milling machine is biomechanical, ideal for producing parts with complex geometries.

Choosing the Right Vertical Milling Machine

When choosing a **vertical milling machine**, consider factors like machine rigidity, spindle speed, and digital readouts. These features greatly affect precision and efficiency.

Industries That Utilize Vertical Milling Machines

Several industries benefit from **vertical milling machines**, including:

- Automotive

- Aerospace

- Medical Engineering

- Electronics

Case Study: Vertical Milling Machines in Aerospace

Vertical milling machines play a crucial role in the aerospace industry, aiding in the production of precise components that adhere to stringent quality standards.

Maintaining Your Vertical Milling Machine

Maintenance is essential for the longevity and efficiency of a **vertical milling machine**. Regular checks and timely servicing ensure the machine operates smoothly.

Trends in Vertical Milling Machine Technology

Technological advancements have made **vertical milling machines** more efficient. Innovations like CNC (Computer Numerical Control) have revolutionized machining, offering greater accuracy and ease of use.

Environmental Considerations and Sustainability

The machining industry is moving towards sustainable practices. New **vertical milling machines** are designed to be energy-efficient and environmentally friendly, aligning with global sustainability goals.

Conclusion

In conclusion, **vertical milling machines** are a staple in industrial settings due to their versatility, precision, and efficiency. They have a profound impact on multiple industries, making them indispensable tools in modern manufacturing.

Internal Links

External Links

FAQs about Vertical Milling Machines

What materials can vertical milling machines work on?

Vertical milling machines are versatile and can work on a variety of materials, including metals, plastics, and wood.

How does a vertical milling machine differ from a horizontal milling machine?

The main difference is the orientation of the spindle. In vertical milling machines, the spindle is vertical, whereas, in horizontal milling machines, it is horizontal.

Are vertical milling machines suitable for heavy-duty tasks?

Yes, vertical milling machines are suitable for both light and heavy-duty tasks, making them a versatile choice for industrial applications.

For further reading on different machines, you might find this external link useful.