In the vast world of manufacturing, machining plays a crucial role. One of the most important machines in this domain is the turret milling machine. Understanding what is a turret milling machine can provide insights into its tremendous applications and technology. This article will delve deep into the workings, benefits, and applications of turret milling machines, offering a comprehensive view for industry QA professionals.

What is a Turret Milling Machine?

Definition

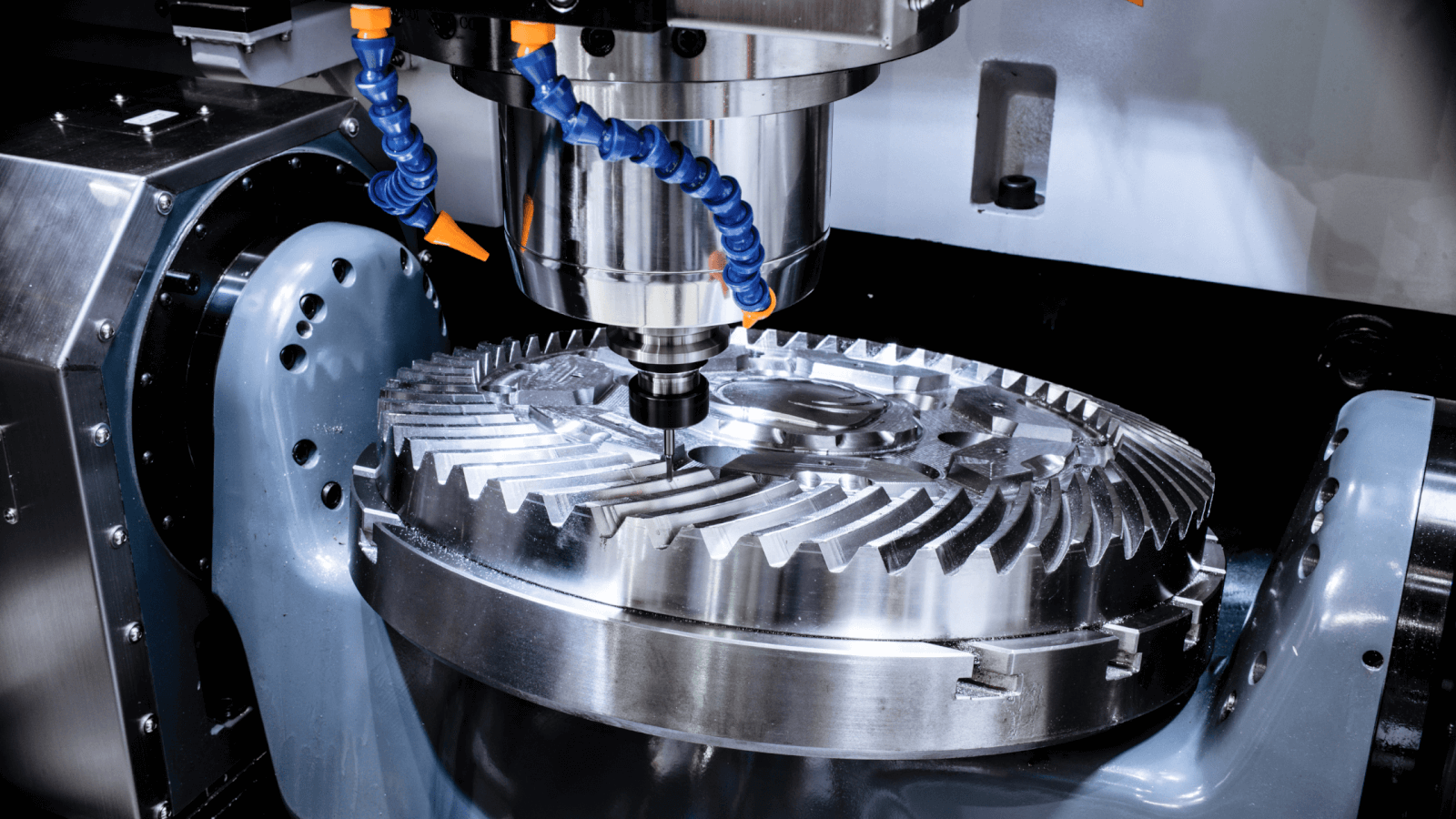

A turret milling machine is a type of vertical milling machine where the spindle remains stationary during the machining process. Unlike other milling machines, the spindle in turret milling machines can be aligned to various positions, allowing for more versatile machining operations.

History of Turret Milling Machines

The invention of milling machines revolutionized the manufacturing process in the late 19th century. The turret milling machine, a more advanced version, came into existence to meet the increasing demand for precise and efficient machining. Its unique design has paved the way for numerous innovations in the field.

Components of a Turret Milling Machine

The Spindle

The spindle is the heart of the turret milling machine. It holds the cutting tool and rotates at varying speeds depending on the material being machined. The spindle’s design allows for precise and steady cutting, ensuring high-quality outputs.

The Turret

The turret is a rotating mechanism that holds multiple tools. This allows operators to switch between different tools without changing the setup, enhancing efficiency and reducing downtime.

Table

The table in a turret milling machine is where the workpiece is placed. It moves in various directions to enable precise cutting. The table’s movement is crucial for achieving the desired shape and size of the workpiece.

The Knee

The knee is a vertical positioning device that supports the table and provides stability. It can be adjusted to different heights, allowing for varied machining operations.

Other Components

Other components of a turret milling machine include the base, column, saddle, and power feed unit. Each part plays a vital role in ensuring smooth and efficient operations.

Working Principle of a Turret Milling Machine

Understanding the working principle of a turret milling machine can help professionals appreciate its efficiency and versatility. The machine operates by rotating the spindle and the attached cutting tool while the table moves. By adjusting the table’s position, the operator can achieve precise cuts on the workpiece.

Step-by-Step Process

- Setup: The workpiece is securely clamped onto the table.

- Tool Selection: Based on the desired operation, the appropriate tool is selected and fixed to the spindle.

- Spindle Rotation: The spindle is powered, causing the cutting tool to rotate.

- Table Movement: The operator adjusts the table’s position to bring the workpiece into contact with the cutting tool.

- Machining: The cutting tool removes material from the workpiece to achieve the desired shape and size.

Benefits of Using a Turret Milling Machine

Precision

Turret milling machines are renowned for their precision. The spindle’s stability and the table’s customizable movements allow for highly accurate machining, vital for industries where even the slightest deviation can lead to significant issues.

Versatility

The ability to switch between multiple tools quickly makes turret milling machines exceptionally versatile. They can perform various operations, from drilling to cutting, on different materials, making them indispensable in a modern manufacturing setup.

Cost-Effectiveness

While turret milling machines may have a higher initial cost, their efficiency and versatility lead to long-term savings. Reduced downtime, minimal errors, and the ability to handle multiple tasks make them a cost-effective choice for many industries.

Applications of Turret Milling Machines

In Automotive Industry

The automotive industry relies heavily on turret milling machines for precise component manufacturing. From engine parts to body components, these machines ensure that every piece meets stringent quality standards.

In Aerospace Industry

The aerospace industry demands the highest precision levels, and turret milling machines deliver just that. They are used to manufacture critical components like turbine blades and structural parts, ensuring safety and reliability.

In Medical Device Manufacturing

Medical devices require absolute precision. Turret milling machines are instrumental in producing medical instruments, implants, and other equipment, ensuring they meet strict industry standards.

In Metalworking Shops

Metalworking shops benefit greatly from the versatility and precision of turret milling machines. They are used for various operations like cutting, drilling, and shaping metal parts.

Maintenance of Turret Milling Machines

Regular Inspection

Regular inspection of all components ensures the machine operates smoothly. Checking for wear and tear and addressing any issues promptly can prevent major breakdowns.

Lubrication

Proper lubrication of moving parts reduces friction, ensuring smooth operation and extending the machine’s lifespan.

Calibration

Calibration of the spindle, table, and other components ensures that the machine operates at peak precision, reducing errors in the final product.

Conclusion

The turret milling machine is a marvel of modern technology, offering precision, versatility, and efficiency. Its applications span various industries, and its importance in manufacturing cannot be overstated. For more detailed insights on milling machines, visit this link. Additionally, check out internal resources on semiconductor inspection and paint and coating inspection.

Frequently Asked Questions (FAQs)

What are the main components of a turret milling machine?

The main components include the spindle, turret, table, knee, and other parts like the base and column.

How does a turret milling machine differ from other milling machines?

The primary difference is the stationary spindle and the rotating turret that allows for tool changes without altering the machine’s setup.

What industries benefit the most from turret milling machines?

Industries like automotive, aerospace, medical device manufacturing, and metalworking shops benefit significantly due to the machine’s precision and versatility.

Where can I learn more about milling machines?

For more detailed information on milling machines, visit this link.

For related applications, explore our internal resources on genetic analysis and event detection in wafer polishing.