Finding the best milling machine is essential for any industry looking to improve effectiveness and precision in their manufacturing process. Understanding the technology and types of milling machines available can save time and money, as well as produce quality products.

Understanding Milling Machines

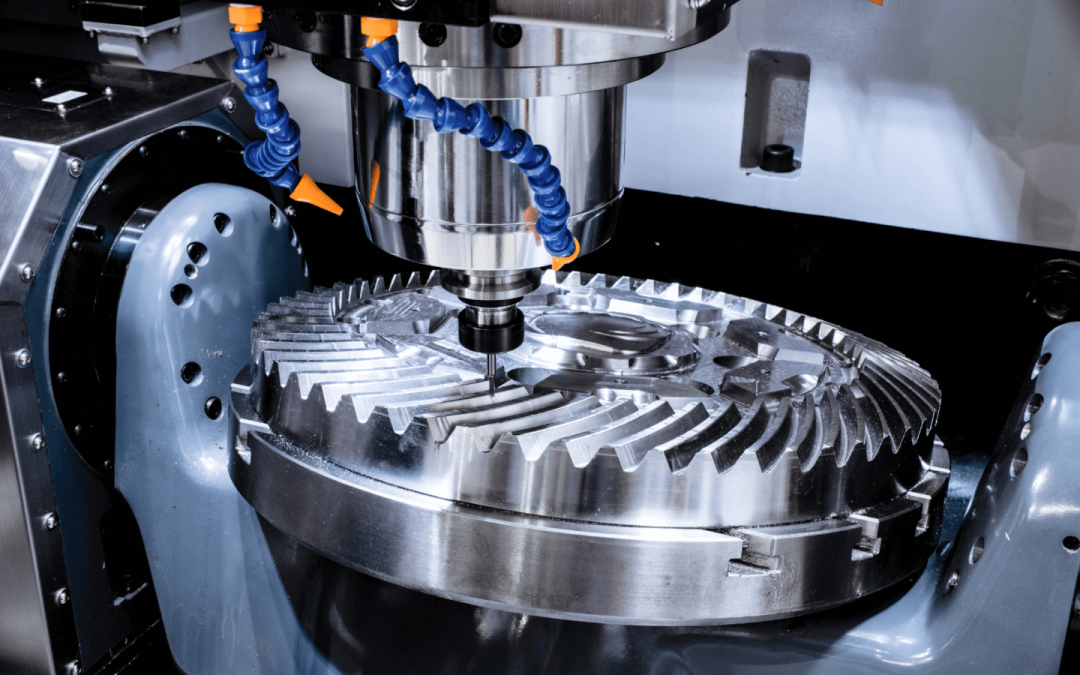

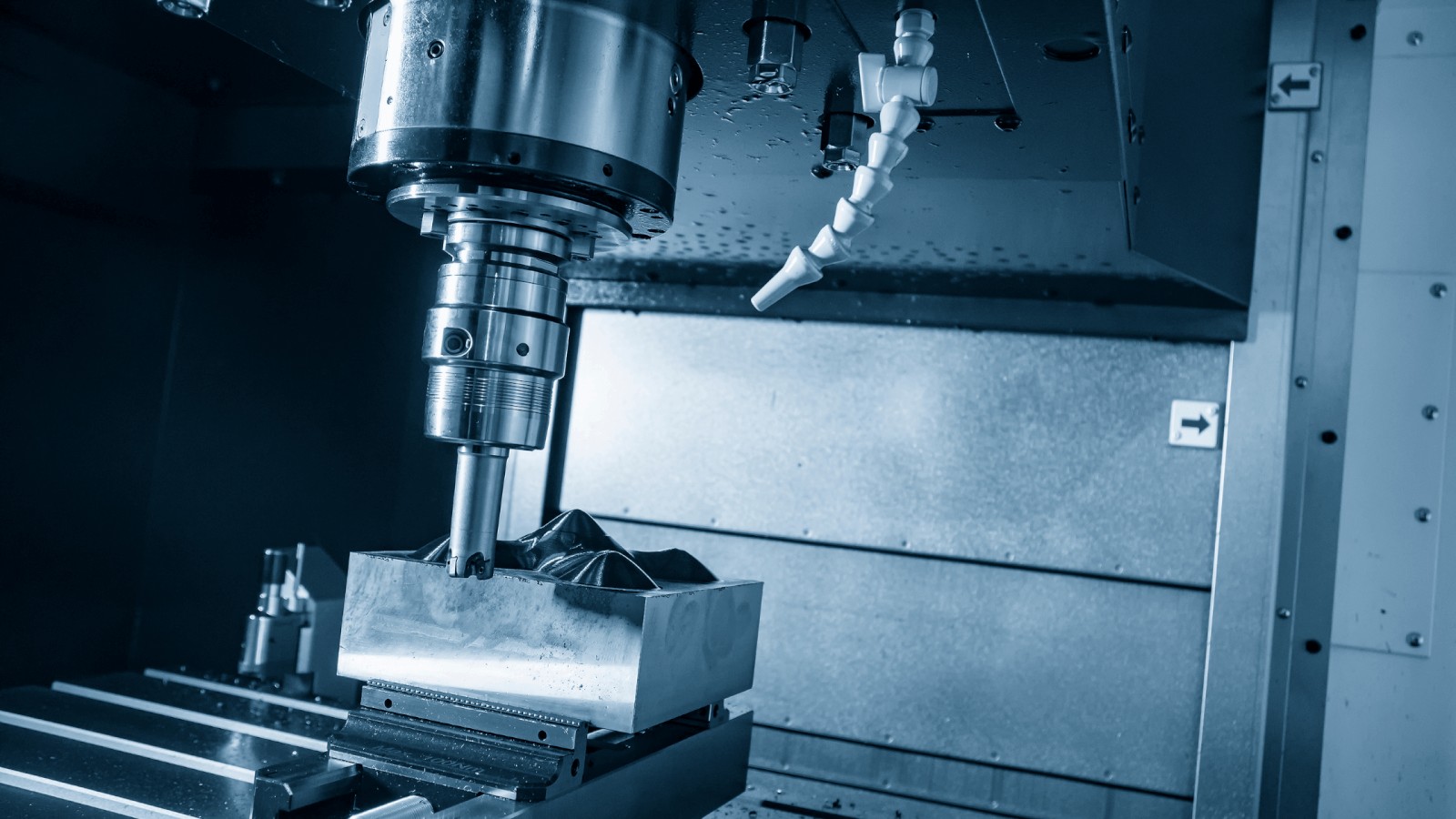

Milling machines are tools used for the purpose of shaping and cutting solid materials such as metal, wood, and plastic. They operate by feeding the material to be cut into a rotating cutter that removes material along the desired plane, creating parts with precise dimensions and finishes.

What is Milling?

Milling involves the process of using rotary cutters to remove material from a workpiece by advancing (or feeding) in a direction at an angle with the axis of the tool. The cutting action of the rotating tool generates very high precision finishing on the material.

Types of Milling Machines

- Horizontal Milling Machine

- Vertical Milling Machine

- Universal Milling Machine

- CNC Milling Machine

Among these, the CNC Milling Machine has gained popularity due to its precision and ability to automate the milling process.

Horizontal vs. Vertical Milling Machines

Horizontal and vertical milling machines form the backbone of the milling industry. Understanding the differences between them can help in selecting the best machine for specific applications.

Horizontal Milling Machine

Horizontal milling machines have cutters that resemble the circular saws. They are mounted on a horizontal arbor. These machines are great at making slots, and are used in industries requiring a lot of material removal work. For more information, refer [here](https://en.wikipedia.org/wiki/Milling_(machining)) on .

Vertical Milling Machine

Vertical milling machines have the spindle in a vertical position. The spindle can move up and down, and the table where the workpiece is placed can also move. They are used for applications requiring precision and accuracy.

Choosing the Right Milling Machine

Choosing the right milling machine involves understanding the needs of your specific project or business. Factors to consider include:

- Material Type

- Required Precision

- Workload

- Cost

Cost Considerations

The cost of a milling machine varies depending on its features and capabilities. While CNC machines are typically more expensive, their ability to produce complex and precise cuts with minimal manual input makes them a worthwhile investment for many industries.

Milling Machines in Different Industries

Milling machines are used in various industries for different applications. For instance, in the aerospace industry, milling machines are used to create intricate parts from lightweight materials. In the medical field, they are used to make precision surgical tools.

Aerospace Industry

In the aerospace industry, milling machines are used for creating complex parts such as turbine blades and structural components. The precision and reliability of these machines ensure the highest standards of production. For information on advanced processes in aerospace, see [this](https://strobox.ai/high-speed-genetic-analysis-and-sequencing-monitoring/).

Medical Industry

In the medical industry, milling machines are used for making precision implants and surgical instruments. They are crucial for producing high-precision components required in medical devices.

Automotive Industry

Milling machines are also widely used in the automotive industry for creating engine parts, transmission components, and more. The ability to produce high-precision parts is essential for vehicle performance and safety.

Conclusion

In conclusion, the best milling machine for your needs will depend on various factors including the type of project, required precision, materials used, and budget. Understanding the capabilities and applications of different types of milling machines can help you make an informed decision.

FAQ

What are the key differences between horizontal and vertical milling machines?

Horizontal milling machines have rotating cutters that are positioned horizontally, while vertical milling machines have the spindle in a vertical position. The choice between them depends on the type of project and required precision.

Why is a CNC milling machine more expensive?

CNC milling machines are more expensive because they offer higher precision, automation, and the ability to produce complex parts with minimal manual input.

Which industries use milling machines?

Milling machines are used in various industries, including aerospace, medical, and automotive, for creating high-precision components.

Check this for more detailed information on Milling Machine definition, process, and types.