Introduction

For industry professionals, understanding the distinctions between different types of milling machines is crucial. Specifically, the difference between horizontal and vertical milling machines is a significant factor in optimizing production processes. Whether you are a seasoned technician or a manager seeking the best equipment, this article will help you navigate the intricate details of both machine types.

Overview of Milling Machines

Milling machines are indispensable in the manufacturing sector. They serve a multitude of functions, from shaping surfaces to drilling and cutting through various materials. These versatile machines come in two primary categories: horizontal and vertical milling machines. Each type has its particular advantages and applications, which we will explore in depth.

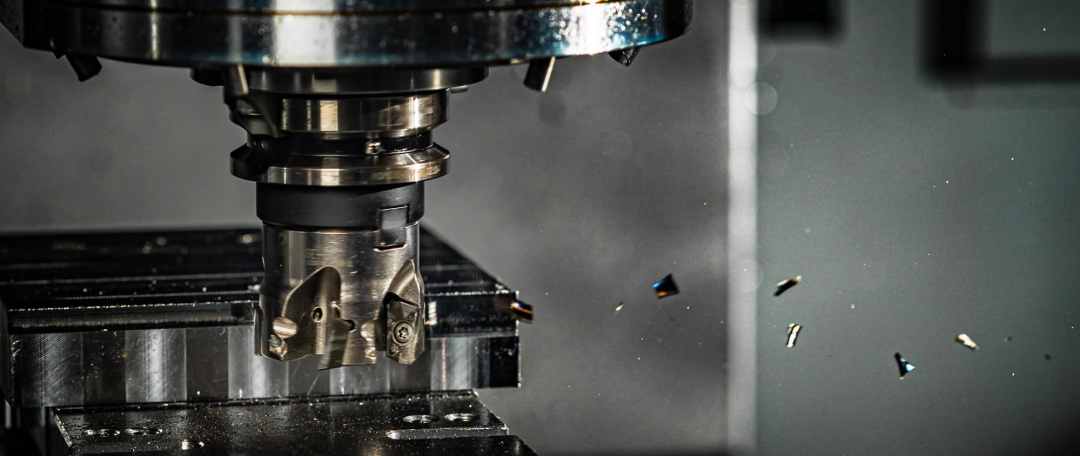

Horizontal Milling Machines Explained

A horizontal milling machine features a horizontal spindle axis, which contributes to its unique mode of operation. Here, the cutting tools are positioned on a horizontal arbor, allowing the workpiece to be fed into the rotating cutter. This setup is exceptionally effective for heavy-duty tasks and large-scale object milling.

Key Features of Horizontal Milling Machines

- Spindle Orientation: Horizontal

- Enhanced Stability: Ideal for large, heavy workpieces

- Versatile Cutting Capabilities: Can perform multiple operations with various tools

Applications of Horizontal Milling Machines

Horizontal milling machines excel in high-volume operations, particularly in the automotive, aerospace, and heavy machinery sectors. Their ability to handle substantial workpieces makes them invaluable for tasks involving large volumes of material removal.

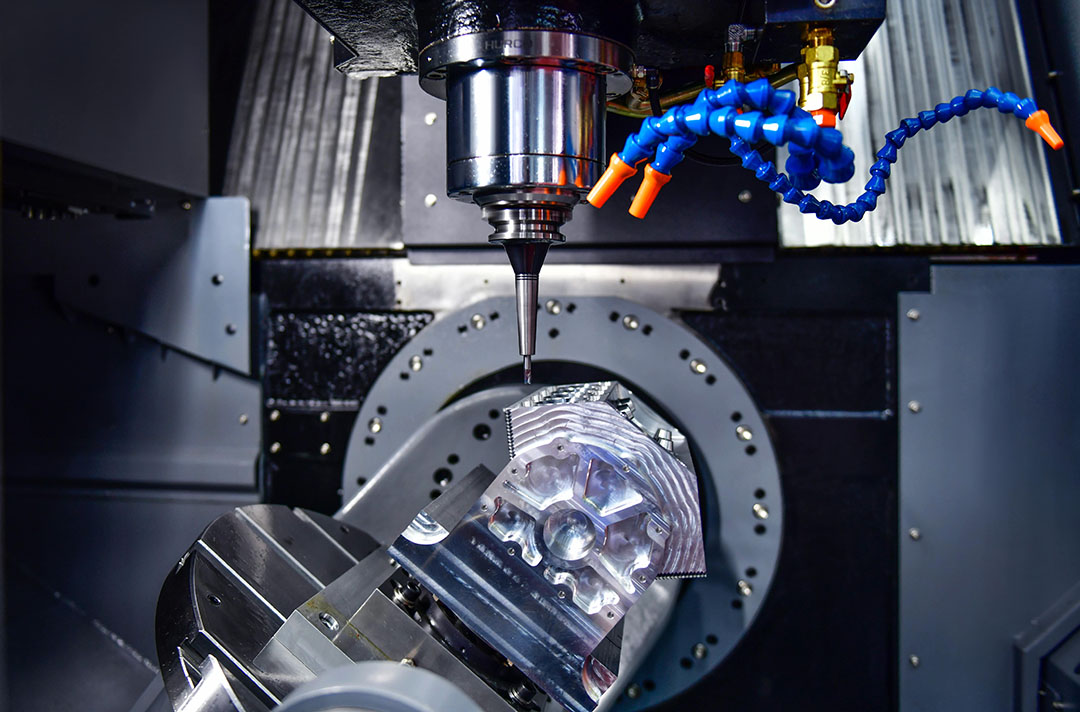

Vertical Milling Machines Explained

In contrast, vertical milling machines have vertically oriented spindles. This design allows for more precise, detailed work on smaller pieces. The cutting tools are mounted vertically and move up and down to remove material from the workpiece.

Key Features of Vertical Milling Machines

- Spindle Orientation: Vertical

- Precision and Detail: Suitable for intricate tasks

- Ease of Use: User-friendly interface

Applications of Vertical Milling Machines

Vertical milling machines are widely used in small-scale manufacturing, precision engineering, and die-sinking applications. They are essential for tasks that require detailed craftsmanship and precision.

Comparative Analysis: Horizontal vs. Vertical Milling Machines

Understanding the differences and similarities between horizontal and vertical milling machines is crucial for selecting the right equipment. Let’s delve into a comparative analysis based on various parameters.

Workpiece Orientation and Spindle Alignment

Horizontal milling machines position the workpiece horizontally, while vertical milling machines hold it vertically. This fundamental difference influences the type of work each machine can perform.

Cutting Efficiency and Versatility

Horizontal milling machines offer higher cutting efficiency for heavy-duty tasks but might lack the precision provided by vertical milling machines. Conversely, vertical machines excel in detailed operations but may not be as robust for large-scale projects.

Space Requirements and Accessibility

Vertical milling machines generally occupy less space, making them suitable for smaller workshops. They are also easier to set up and use, making them accessible for operators with varying skill levels. Horizontal milling machines, however, may require more space and specialized skills to operate effectively.

Technological Innovations and Improvements

Both horizontal and vertical milling machines have benefited from technological advancements. Modern machines incorporate CNC (Computer Numerical Control) technology, enhancing precision, efficiency, and automation in milling operations.

Case Studies: Real-world Applications

Lets consider some real-world case studies to illustrate the differences between horizontal and vertical milling machines.

Case Study 1: Automotive Industry

In the automotive industry, horizontal milling machines play a pivotal role in manufacturing engine blocks and other large components. Their stability and capability to handle substantial workpieces make them indispensable.

Case Study 2: Aerospace Engineering

Aerospace engineers often rely on vertical milling machines for creating intricate components such as turbine blades and aircraft parts. The precision and detail offered by vertical milling machines are crucial in this high-stakes industry.

Economic Considerations

When choosing between horizontal and vertical milling machines, cost is always a significant factor. Horizontal milling machines tend to be more expensive due to their complex design and robust capabilities. On the other hand, vertical milling machines are generally more affordable and easier to maintain.

Challenges and Solutions

Both types of milling machines come with their set of challenges. Horizontal machines may require more frequent maintenance due to their heavy-duty nature, while vertical machines might struggle with larger, more demanding tasks. However, advancements in technology continue to provide solutions to these issues, ensuring operational efficiency and reduced downtime.

Environmental Impact

The environmental impact of milling operations cannot be overlooked. Horizontal milling machines, due to their high material removal rate, often result in more waste. Vertical milling machines, while generating less waste, need efficient systems to manage smaller, more frequent material disposal.

Safety Considerations

Safety is paramount in any machining operation. Horizontal milling machines, with their robust design and high torque, require strict safety protocols, including proper guarding and operator training. Vertical milling machines, while generally safer, still necessitate adherence to safety standards to prevent accidents.

Choosing the Right Machine for Your Needs

Selecting between a horizontal and vertical milling machine depends on various factors, including the nature of your projects, space availability, and budget considerations. Both machine types have their strengths and weaknesses, and understanding these can guide you in making an informed decision.

Conclusion

In summary, the difference between horizontal and vertical milling machines is not just in their physical orientation but also in their capabilities and applications. Horizontal machines are suited for heavy-duty, large-scale operations, while vertical machines excel in precision and detail-oriented tasks. By understanding these distinctions, you can better select the right equipment to meet your manufacturing needs.

FAQs

What are the main differences between horizontal and vertical milling machines?

The primary difference lies in the spindle orientation: horizontal machines have a horizontal spindle, while vertical machines have a vertical spindle. This affects the types of operations they can perform, their efficiency, and their suitability for different tasks.

Which type of milling machine is more cost-effective?

Vertical milling machines are generally more affordable than horizontal ones both in terms of initial cost and maintenance. However, the choice should be based on your specific project needs and budget.

Are horizontal milling machines better suited for high-volume operations?

Yes, horizontal milling machines are designed for high-volume, heavy-duty tasks. They offer stability and versatility, making them ideal for large-scale manufacturing processes.

For more detailed insights on milling machines, you can visit Britannica.

To read more about related topics, check out our internal resources on application inspection, manufacturing inspection, and wafer polishing.