Introduction

Handling industrial equipment like a milling machine requires not only precision but also careful planning. Knowing how to lift a milling machine safely and efficiently is essential for ensuring workplace safety and maintaining equipment integrity. In this comprehensive guide, we will delve into the crucial steps and considerations for lifting a milling machine correctly.

Understanding the Basics

What is a Milling Machine?

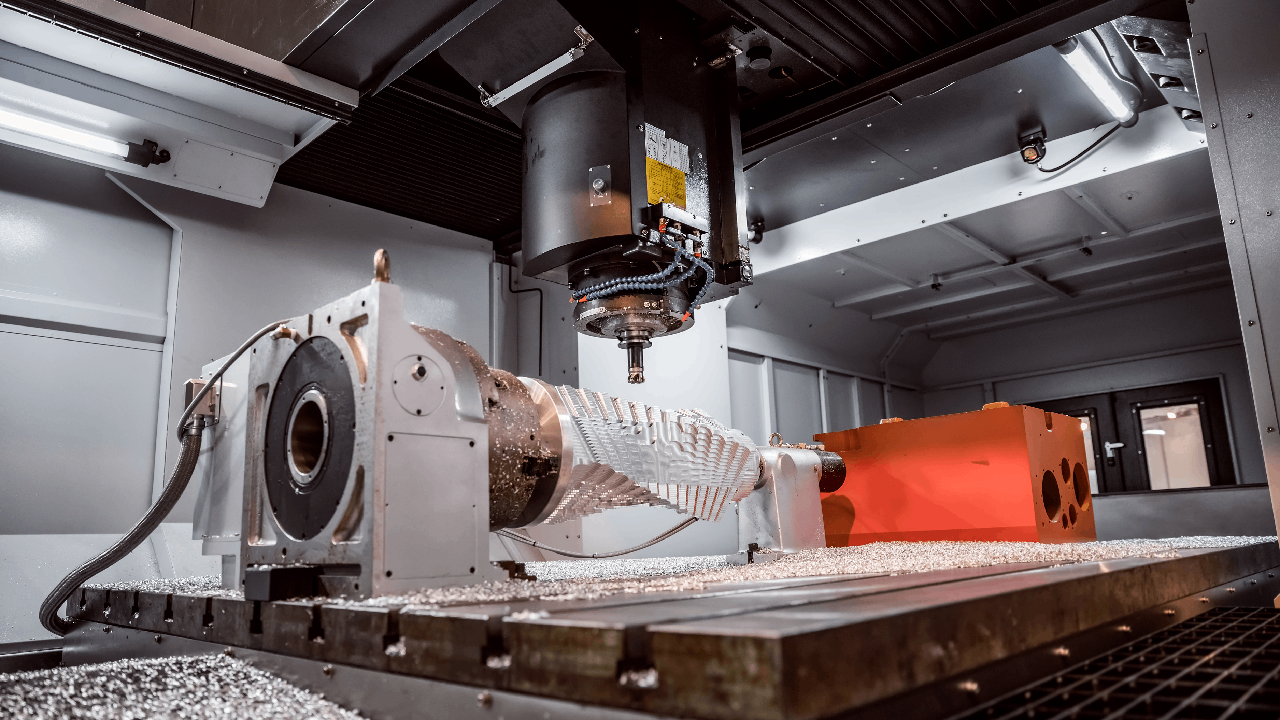

A milling machine is a powerful industrial tool used for shaping and cutting materials. It operates on various axes to achieve intricate cuts and designs. These machines are commonly used in manufacturing and engineering fields.

Importance of Proper Handling

Improper handling of milling machines can lead to serious accidents, equipment damage, and costly repairs. Hence, understanding the right way to lift and move these machines is crucial.

Preparing for the Lift

Assessing the Machine’s Weight and Dimensions

Before lifting, it’s important to assess the weight and dimensions of the milling machine. Refer to the machine’s manual or specifications to determine its weight. This information will help you choose the appropriate lifting equipment.

Selecting the Right Lifting Equipment

Depending on the size and weight of the milling machine, you may need different types of lifting equipment, such as forklifts, cranes, or hoists. Ensure that the equipment you choose is capable of safely lifting the machine.

Step-by-Step Guide to Lifting a Milling Machine

Step 1: Inspect the Area

Before starting the lift, inspect the surrounding area to ensure it is clear of obstacles and hazards. This will help prevent accidents during the lifting process.

Step 2: Secure the Machine

Use straps, chains, or lifting slings to secure the milling machine properly. Make sure the machine is balanced to avoid tipping during the lift.

Step 3: Position the Lifting Equipment

Position the lifting equipment (e.g., forklift or crane) correctly under the milling machine. Ensure the lifting points are aligned with the machine’s center of gravity.

Step 4: Lift the Machine

Using the lifting equipment, slowly and steadily lift the milling machine. Avoid sudden or jerky movements to prevent destabilization.

Step 5: Move to Desired Location

Once the milling machine is lifted, carefully move it to the desired location. Ensure the path is free from obstacles, and use spotters if necessary.

Ensuring Safety During the Lift

Wearing Protective Gear

Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots, when lifting heavy machinery.

Using Trained Personnel

Ensure that the personnel involved in the lifting process are trained and experienced in handling heavy equipment. This reduces the risk of accidents and ensures a smooth operation.

Post-Lift Procedures

Inspecting the Machine

After the milling machine is in place, conduct a thorough inspection to ensure it is properly positioned and secured. Check for any signs of damage that may have occurred during the lift.

Testing the Machine

Before resuming normal operations, perform a test run of the milling machine to ensure it is functioning correctly. This helps identify any issues that need to be addressed.

Common Mistakes to Avoid

Ignoring Weight Limits

One of the most common mistakes is ignoring the weight limits of the lifting equipment. Always adhere to the recommended weight capacities to avoid equipment failure.

Improper Securing of the Machine

Failing to secure the milling machine properly can result in accidents and damage. Double-check all straps, chains, and slings before lifting.

Tips for Efficient Lifting

Planning the Lift

Proper planning is key to efficient lifting. This includes assessing the machine, selecting the right equipment, and ensuring all safety measures are in place.

Clear Communication

Ensure clear communication among all team members involved in the lifting process. Use hand signals or radios to coordinate movements and actions.

Conclusion

Knowing how to lift a milling machine safely and efficiently is essential for any industrial setting. By following the steps outlined in this guide and prioritizing safety, you can ensure a smooth and accident-free lifting process.

FAQs

1. What is the most important factor to consider when lifting a milling machine?

The most important factor is ensuring the machine is balanced and securely fastened to avoid tipping or falling during the lift.

2. Can I lift a milling machine without professional help?

It is highly recommended to seek professional help or use trained personnel to lift a milling machine to ensure safety.

3. What should I do if the milling machine gets damaged during the lift?

If the machine gets damaged, stop the lift immediately and assess the damage. It may be necessary to contact a professional for repairs.