In the realm of modern machining, understanding what rotates on a milling machine is crucial for achieving optimal results. Milling machines are pivotal in manufacturing processes, ensuring precision and efficiency. Lets dive deeply into this tremendous technology that enhances productivity in various industries.

The Core Element: Spindle

A central component that rotates in a milling machine is the spindle. The spindle is responsible for holding and rotating the milling cutter. It’s a vital part affecting the machining process’s precision and efficiency.

Milling Cutters: Types and Functions

End Mills

End mills are a type of milling cutter that rotates on the machine’s spindle. They are used for various tasks, including cutting, slotting, and contouring. Different types of end mills such as square end mills, ball nose mills, and chamfer mills, serve distinct purposes in machining.

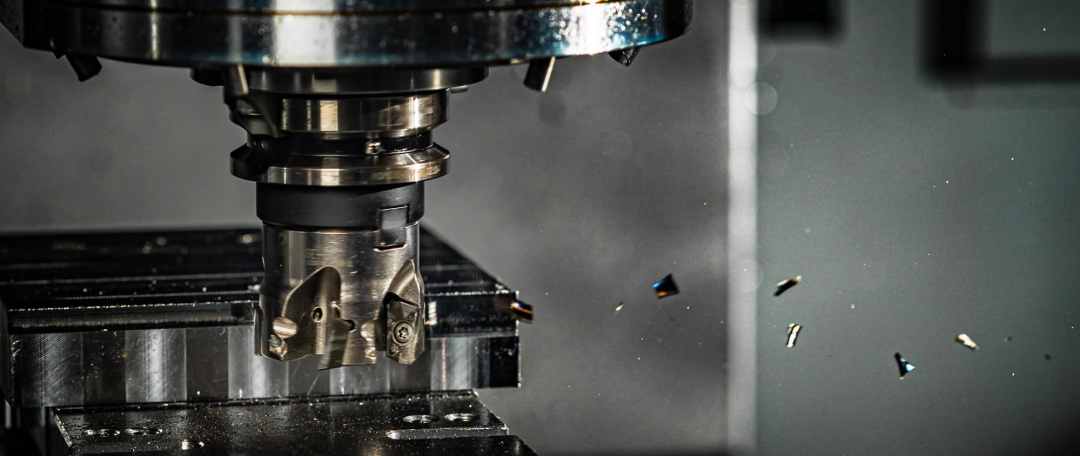

Face Mills

Face mills are large diameter cutters that deliver a smooth finish to workpieces. These milling cutters are typically used in the first step of roughing operations, providing tremendous efficiency.

Tool Holders: Keys to Precision

Tool holders are essential for keeping the milling cutters in place. A well-secured tool is less likely to deflect during operation, ensuring accuracy.

The Role of Worktables

The worktable in a milling machine is where the workpiece is positioned. Though it doesnt rotate, its precision movements are synchronized with the rotating spindle to achieve the desired design.

Machining Operations: Delighted With Variety

Milling machines can perform various operations thanks to the rotating components. These operations include:

- Face Milling

- Peripheral Milling

- Slotting

- Drilling

Face Milling

This operation uses face mills to remove material from the surface of a workpiece, providing a smooth finish. Its a crucial step in ensuring the workpiece meets design specifications.

Peripheral Milling

Peripheral milling involves cutting along the workpieces edges using end mills. It’s used for contouring and slotting operations, requiring precision in the rotating spindle.

For advanced applications in machining, you can explore Semiconductor inspections.

Essential Maintenance Tips

Regular maintenance of milling machine components ensures longevity and consistent performance. Key areas to focus on include:

- Lubrication of the spindle and bearings

- Checking and replacing worn-out milling cutters

- Ensuring tool holders remain tight and secure

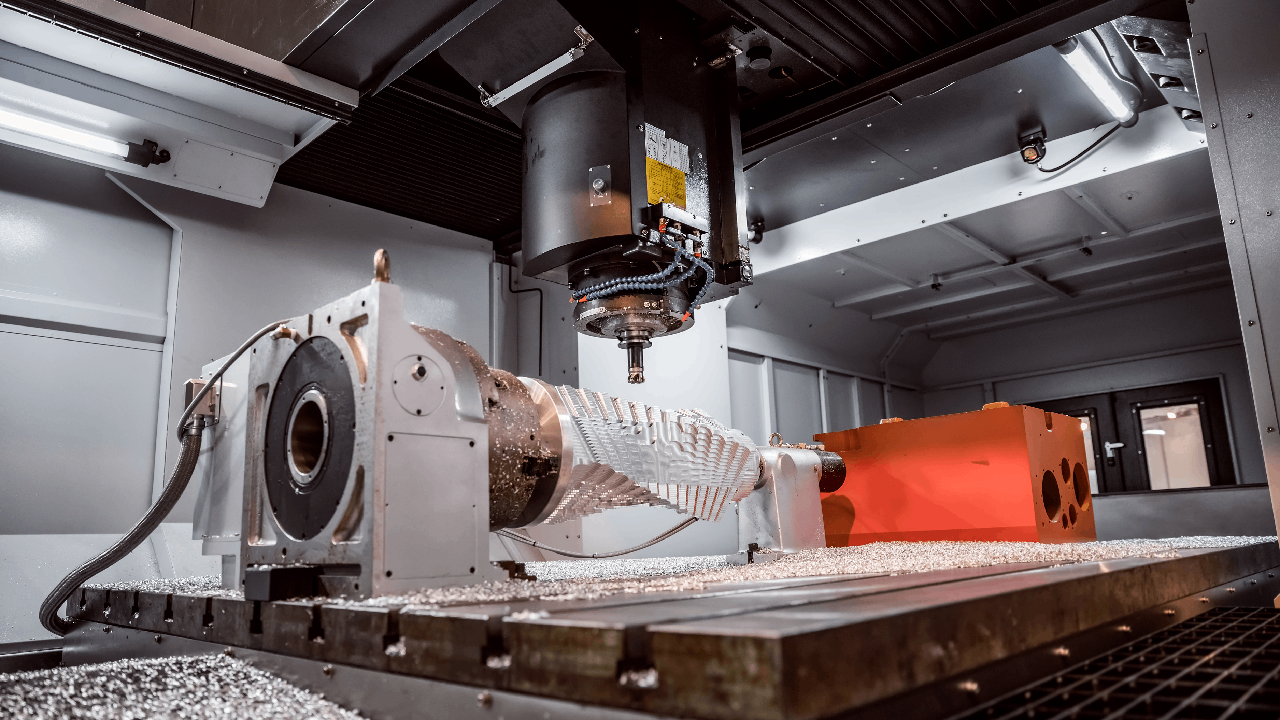

Technological Advancements in Milling Machines

Modern milling machines incorporate advanced technologies such as CNC (Computer Numerical Control), allowing for automated and precise operations. These innovations are revolutionizing the industry, making operations faster and more efficient.

Computer Numerical Control (CNC)

CNC technology allows for automated control of milling machines, enhancing precision and efficiency. Machines equipped with CNC can produce complex parts with minimal human intervention.

Frequently Asked Questions

What is the primary function of a spindle in a milling machine?

The primary function of the spindle is to hold and rotate the milling cutter, enabling various machining operations.

How do end mills differ from face mills?

End mills are used for contouring, slotting, and cutting, whereas face mills are primarily used for surface finishing operations.

What role do tool holders play in a milling machine?

Tool holders keep the milling cutters secure, preventing deflection and ensuring precise machining operations.

For more information on advanced machining processes, visit Wikipedia.