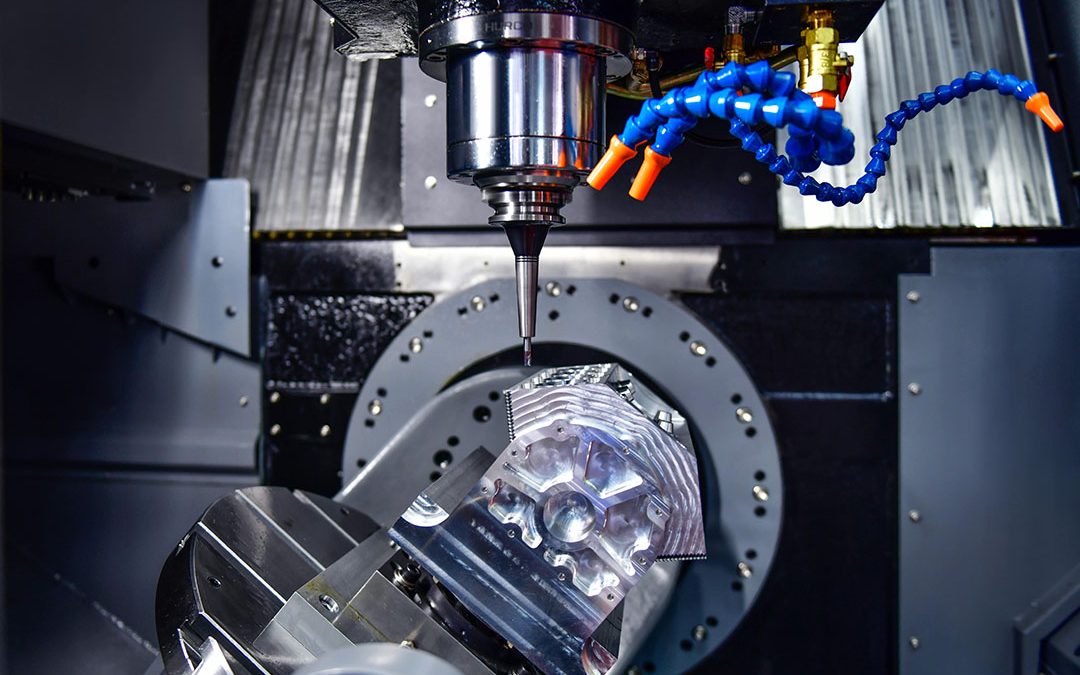

The term backlash in a milling machine refers to the play or clearance between moving parts, typically gears or screws, when they change the direction of movement. Understanding what is backlash on a milling machine is crucial for ensuring precision and accuracy in manufacturing processes.

In this article, we will delve into the intricacies of backlash, its causes, and ways to mitigate it, and discuss its significance in the broader context of milling machines. Whether you are an industry professional or simply curious about milling technology, this article aims to provide a comprehensive and detailed overview. We will also address common questions and concerns related to the topic.

Understanding Backlash

What is Backlash?

Backlash is the clearance or lost motion in a mechanism caused by the gaps between the parts. In the context of milling machines, it typically refers to the slack between gear teeth or the thread of a leadscrew. This slack can cause inaccuracies, especially when the machine changes direction.

Why Does Backlash Occur?

Backlash occurs due to various factors:

- Wear and Tear: Over time, parts of the milling machine may wear out, leading to increased backlash.

- Manufacturing Tolerances: Even new machines have some level of backlash due to the inherent tolerances in the manufacturing process.

- Assembly Errors: Improper assembly can introduce additional play between parts.

Impact of Backlash on Milling Machines

Precision and Accuracy

Backlash can significantly affect the precision and accuracy of a milling machine. When the machine changes direction, the clearance causes a delay before the tool starts moving, leading to inaccuracies in the final product.

Surface Finish

Inconsistent motion due to backlash can also affect the surface finish of the machined part, resulting in rough or uneven surfaces.

Mitigating Backlash

Regular Maintenance

Regular maintenance and calibration can help reduce backlash. Ensuring that components are correctly aligned and lubricated minimizes wear and tear.

High-Precision Components

Using high-precision components with tighter manufacturing tolerances can help reduce the initial level of backlash in a machine.

Anti-Backlash Devices

Devices such as anti-backlash nuts and gears can help compensate for the clearance in the system, improving accuracy.

Advanced Backlash Compensation Techniques

Software Solutions

Modern milling machines often come equipped with software solutions that can compensate for backlash. These systems measure the amount of play and adjust the machine’s movements accordingly.

Feedback Systems

Feedback systems, such as encoders, provide real-time data on the machine’s position, allowing for more precise adjustments and reducing the impact of backlash.

Real-World Applications and Case Studies

Industry Examples

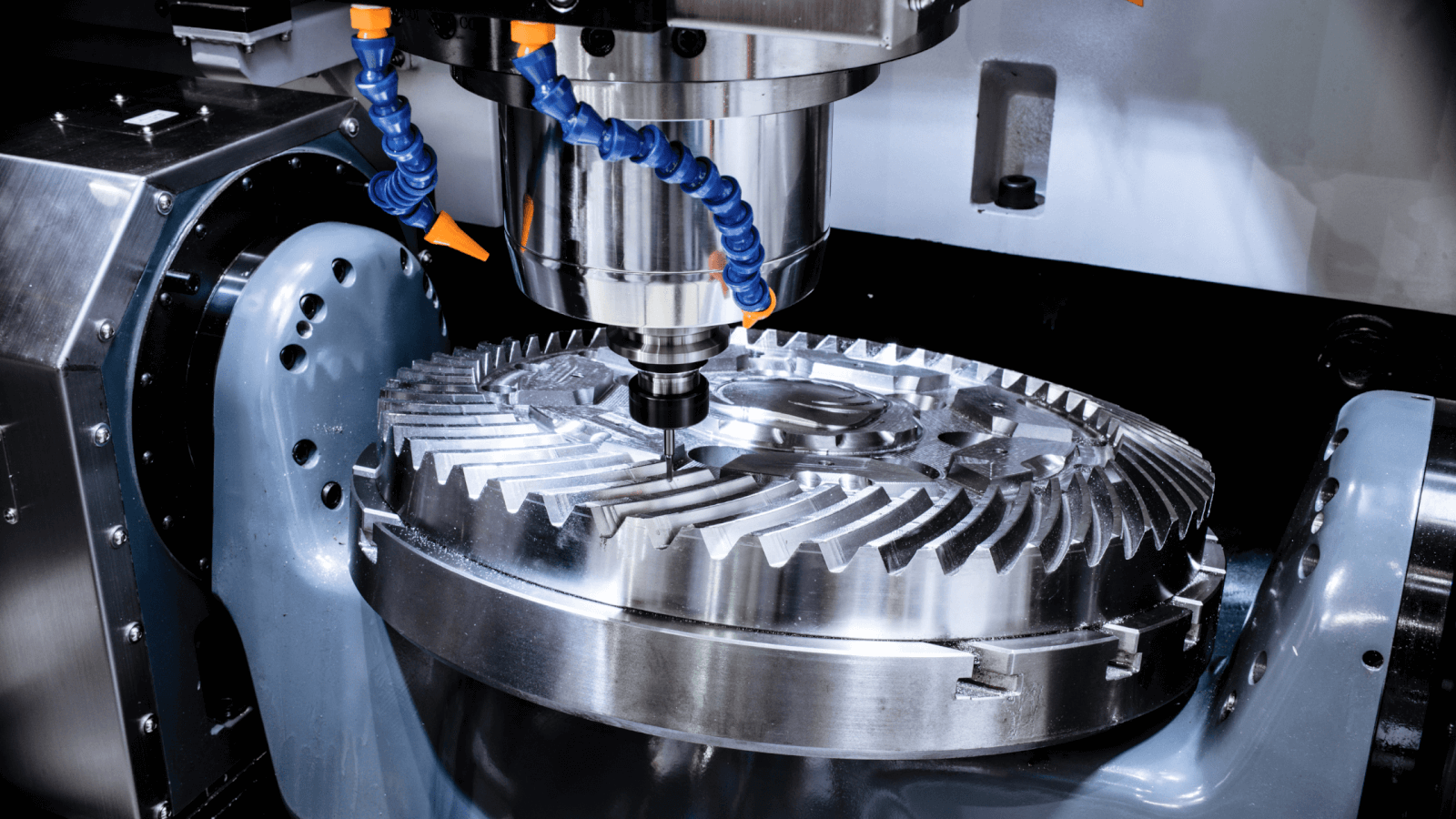

In industries like aerospace and automotive manufacturing, where precision is paramount, understanding and mitigating backlash is essential. These sectors often employ advanced techniques and high-precision machines to maintain accuracy.

Case Study: CNC Milling

In CNC milling, backlash can be particularly problematic due to the complex movements involved. By implementing anti-backlash devices and advanced software solutions, manufacturers can achieve higher accuracy and better surface finishes.

Conclusion

Understanding what is backlash on a milling machine is vital for anyone involved in precision manufacturing. By recognizing its causes and implementing techniques to mitigate it, you can improve the accuracy and quality of your milling processes. Whether through regular maintenance, high-precision components, or advanced software solutions, addressing backlash is crucial for achieving optimal results.

FAQs

What are the common causes of backlash in a milling machine?

Common causes include wear and tear, manufacturing tolerances, and assembly errors.

Can backlash be completely eliminated?

While it is challenging to eliminate backlash entirely, it can be minimized through regular maintenance, high-precision components, and advanced software solutions.

How does backlash affect the accuracy of a milling machine?

Backlash introduces a delay in movement when the machine changes direction, leading to inaccuracies in the final product.

For more information on milling machines and their types, you can visit this article.

For further reading on related topics, check out wafer-polishing, coating-application, and genetic-analysis articles.