If you’ve ever wondered how to level a milling machine, you’re in the right place. Leveling a milling machine ensures precision in your work and prolongs the life of your equipment. This article will delve into the steps required to achieve a perfect level, and bring your machining accuracy up to industry standards.

Why is Leveling Important?

Before diving into the how-to, let’s understand why this is essential. A milling machine operates best when perfectly level, which directly impacts the quality of the machined parts and your productivity.

What Tools Are Needed?

You’ll need a few tools: a precision level, shims, a wrench set, and a dial indicator. These tools will help you through the leveling process smoothly.

Understanding Your Milling Machine

Every milling machine is different. It’s crucial to read the manual which often provides specific instructions and points to consider.

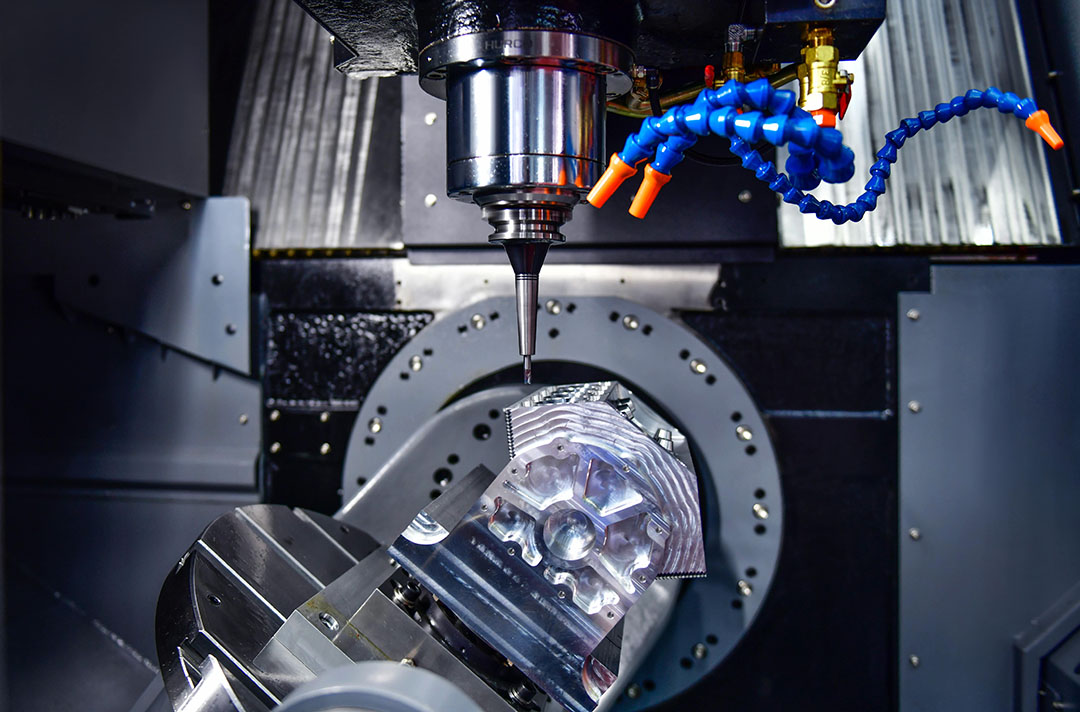

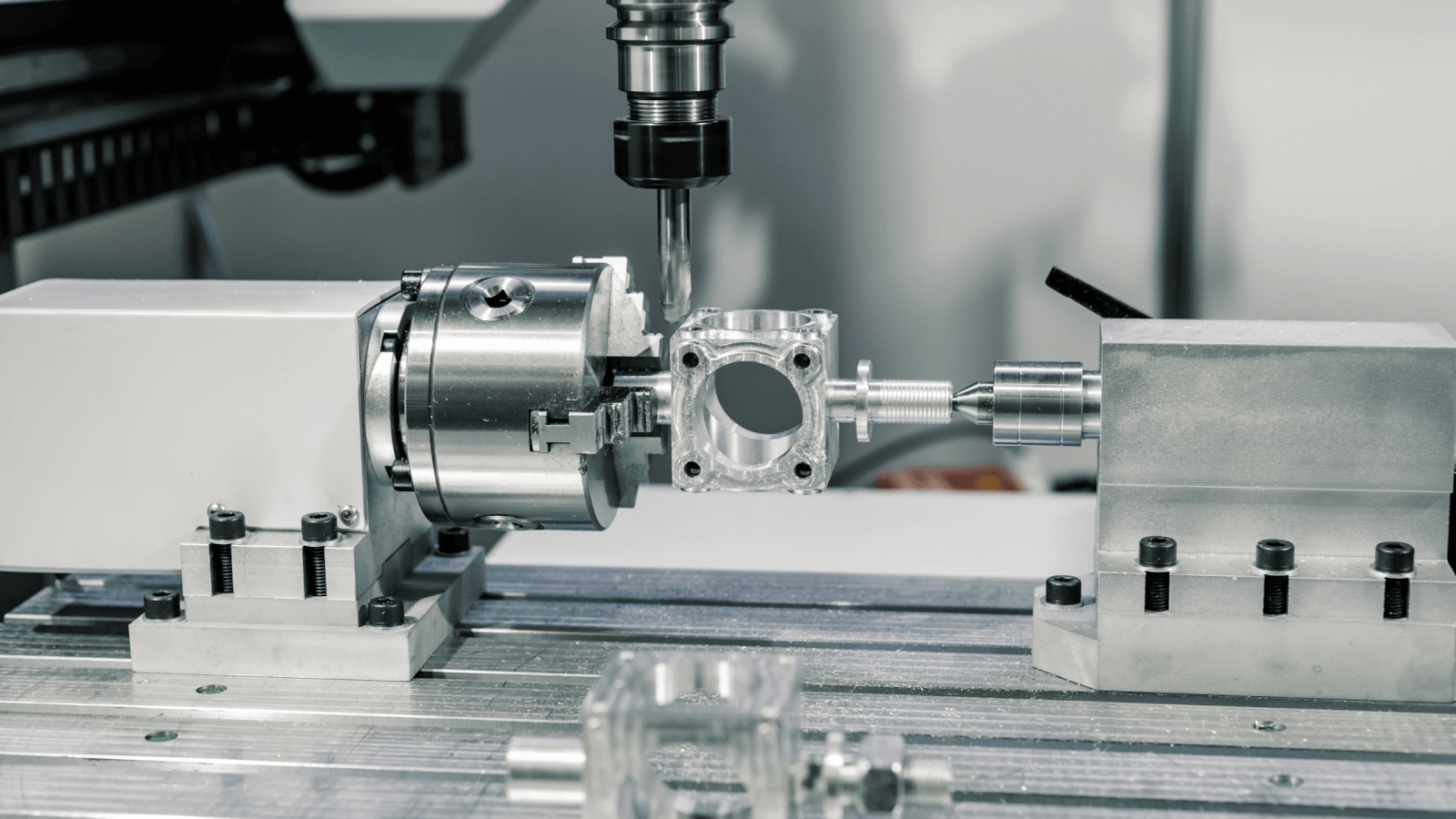

Types of Milling Machines

Understanding your type of milling machine can provide insights into what areas require more attention for leveling.

- Horizontal Milling Machines

- Vertical Milling Machines

Common Leveling Mistakes

Avoid these pitfalls to ensure youre leveling correctly. Improper leveling can result in inaccurate cuts and a shorter machine lifespan.

Step-by-Step Guide to Level a Milling Machine

Step 1: Initial Inspection

Start with a thorough inspection of the machine base. Clean thoroughly and check for obvious defects or warping.

Step 2: Positioning the Machine

Place the machine in its final location. Ensure the floor is stable and free from vibrations.

Step 3: Using the Precision Level

Position the level across various sections of the machine and identify uneven areas. Adjust the leveling feet accordingly.

Step 4: Adding Shims

In cases where the feet can’t be adjusted enough, use shims to achieve a level base.

Step 5: Rechecking Levels

After adjustments, recheck with your precision level until the machine is perfectly level.

Advanced Techniques in Leveling

Using a dial indicator can provide even greater precision. Learn to use this tool for fine adjustments.

Dial Indicator Setup

Attach the dial indicator to evaluate small deviations from the level.

Imbalance Correction

Identify and correct imbalances that may occur due to uneven weight distribution.

Maintenance Tips for Your Milling Machine

Regular maintenance checks and preventive measures can maintain the precision level of your milling machine.

Scheduled Cleaning

Keep your machine clean to prevent debris from affecting the level.

Lubrication Points

Regular lubrication ensures smooth operation and maintains the level.

Frequently Asked Questions

How often should I level my milling machine?

It’s recommended to check the level every few months, depending on usage.

Can I use a digital level for better accuracy?

Yes, digital levels can offer enhanced precision and simplify the leveling process.

What’s the most crucial step in leveling a milling machine?

Ensuring the base is clean and free from defects is vital for achieving a precise level.

Conclusion

Leveling your milling machine is a vital step that ensures precision and productivity. Follow these steps, and youll have a machine that operates at peak efficiency. For more information, visit Britannica – Milling Machines to deepen your understanding.

Also, explore our advanced stroboscopic wafer polishing detection and paint inspection techniques to keep your industrial processes at the forefront of technology.

Stay tuned for more terrific insights on maintaining and optimizing your essential machinery!