Are you delighted to learn how to use an edge finder on a milling machine? You’re in the right place. Today, we’ll take a comprehensive look at the step-by-step process of effectively utilizing this essential tool. Our target audience, perfect for industry QA professionals, will find this guide both informative and highly engaging. So, let’s dive into the world of milling machine technology together!

Introduction to Edge Finders

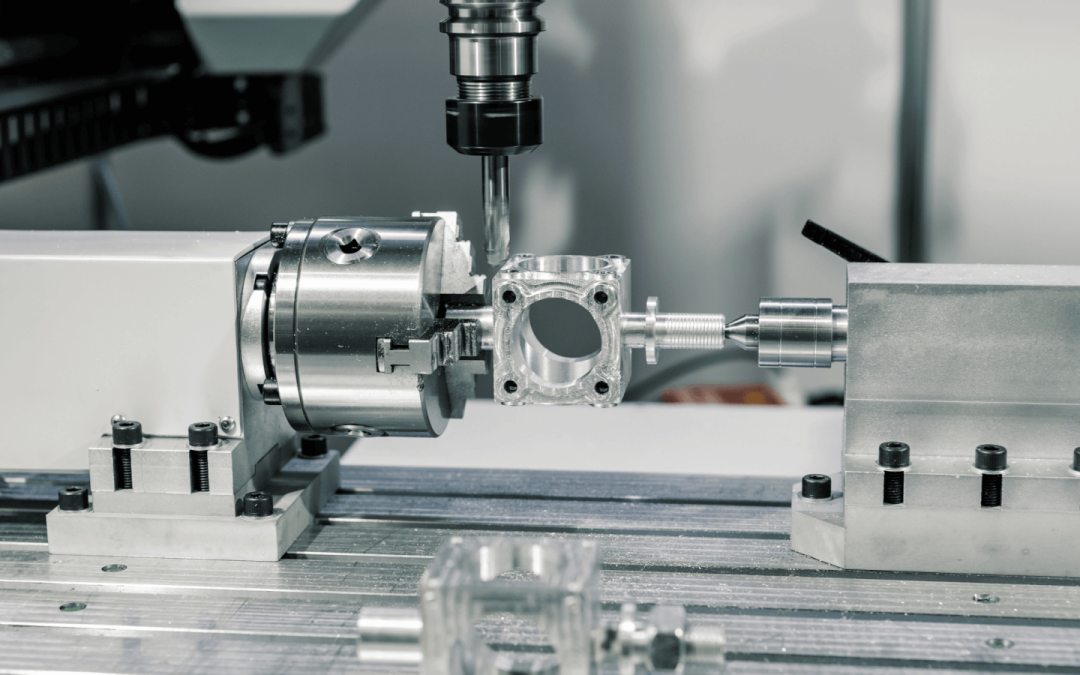

An edge finder is a very commonly used tool in milling. It allows the machinist to locate the edges of a workpiece very precisely, helping in setting up parts accurately.

What is an Edge Finder?

An edge finder is a type of tool used in milling to find the exact edge or center of a workpiece. Being a part of the technology world, it’s considered very accurate for alignment tasks.

Types of Edge Finders

There are primarily two types of edge finders – mechanical and electronic. Each has unique features and specific usage scenarios.

Mechanical Edge Finder

The mechanical type is typically used in conventional milling machines. It is simple to use and widely appreciated for its accuracy.

Electronic Edge Finder

An electronic edge finder, also known as a digital edge finder, is compatible with modern CNC machines. It provides higher precision and is quite easy to use.

Step-by-Step Guide to Using an Edge Finder

Step 1: Setup

The first step in using an edge finder is setting it up in the milling machine spindle.

Step 2: Calibration

Calibrating the edge finder to ensure that it provides precise readings is essential.

Step 3: Finding the Edge

Move the workpiece towards the edge finder slowly until the two parts of the edge finder jump slightly, indicating that the edge has been found.

Step 4: Final Adjustment

After locating the edge, make any final adjustments and set the milling machine to the zero-setting to begin machining.

Tips for Using an Edge Finder on a Milling Machine

- Ensure that your edge finder is clean and free from any particles.

- Wear safety goggles while operating the machine.

- Lubricate moving parts of the edge finder regularly.

Common Mistakes and How to Avoid Them

Avoid common mistakes like moving the workpiece too fast or not calibrating the edge finder. Precision is key!

Advanced Techniques

Once you’re comfortable using an edge finder, you can explore advanced techniques like using it to verify angles or center points.

FAQ

What is the primary use of an edge finder?

Its primary use is to locate the precise edge or center of a workpiece in a milling machine.

Can edge finders be used on CNC machines?

Yes, especially electronic edge finders are designed for use with CNC machines.

How often should I calibrate my edge finder?

Calibration should be done before each new project to ensure the highest accuracy.

For more detailed insights, visit this excellent guide.

To continue learning about inspection and other related technologies, check out our articles on Paint Inspection, Genetic Analysis, and Semiconductor Manufacturing.