Are you intrigued by the intricacies of milling machines? If so, you’ll be delighted to learn about the dividing head, a crucial component in the milling process. But what is a dividing head in milling machine? In this article, we’ll break down everything you need to know about this tremendous piece of technology and its role in enhancing milling operations.

Introduction to Milling Machines

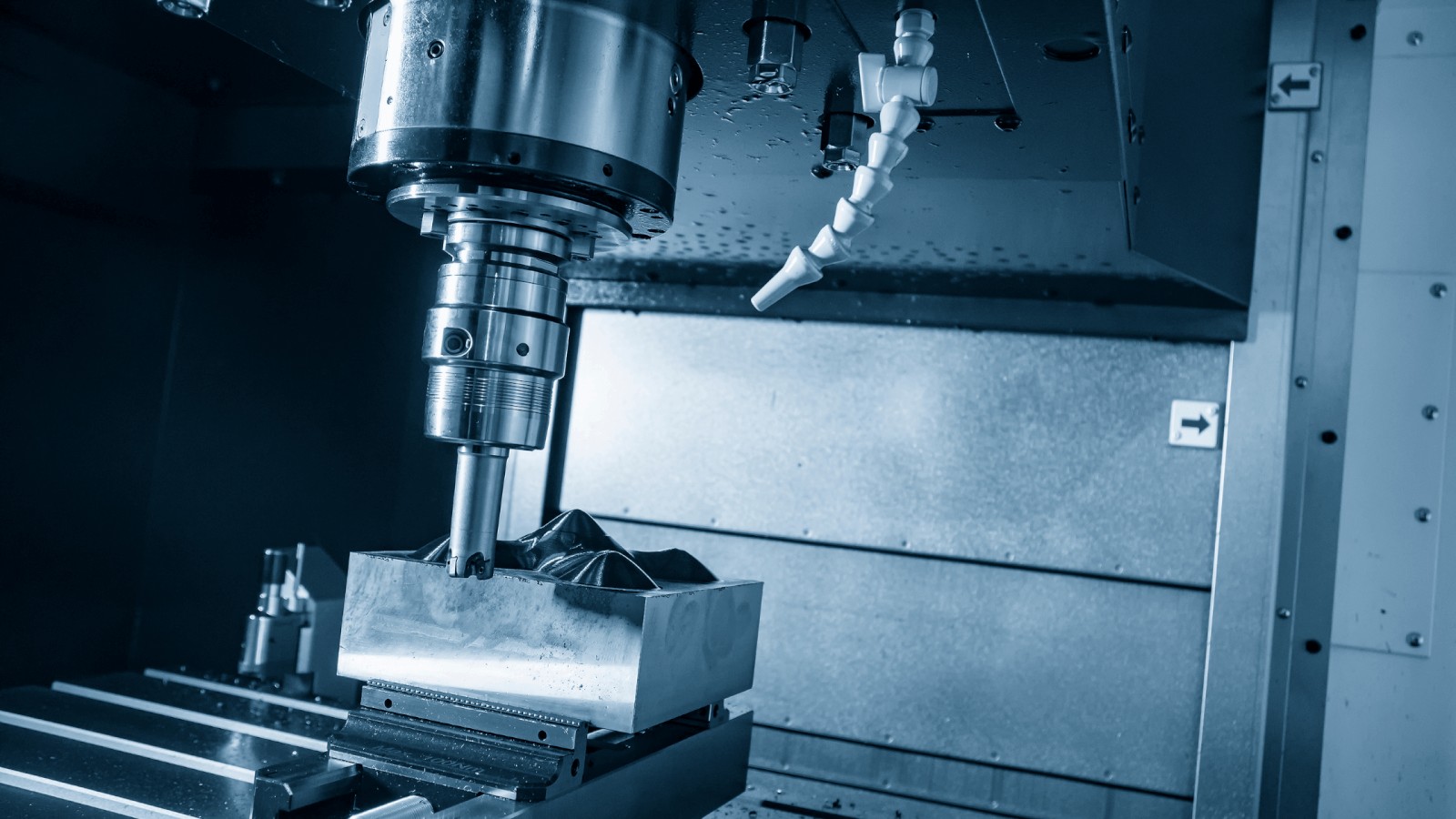

Milling machines are versatile tools used in the manufacturing industry to shape, cut, and drill materials into specific forms. A key feature of these machines is their ability to hold and rotate cutting tools in various directions.

Find out more about milling machines here.

What Is a Dividing Head?

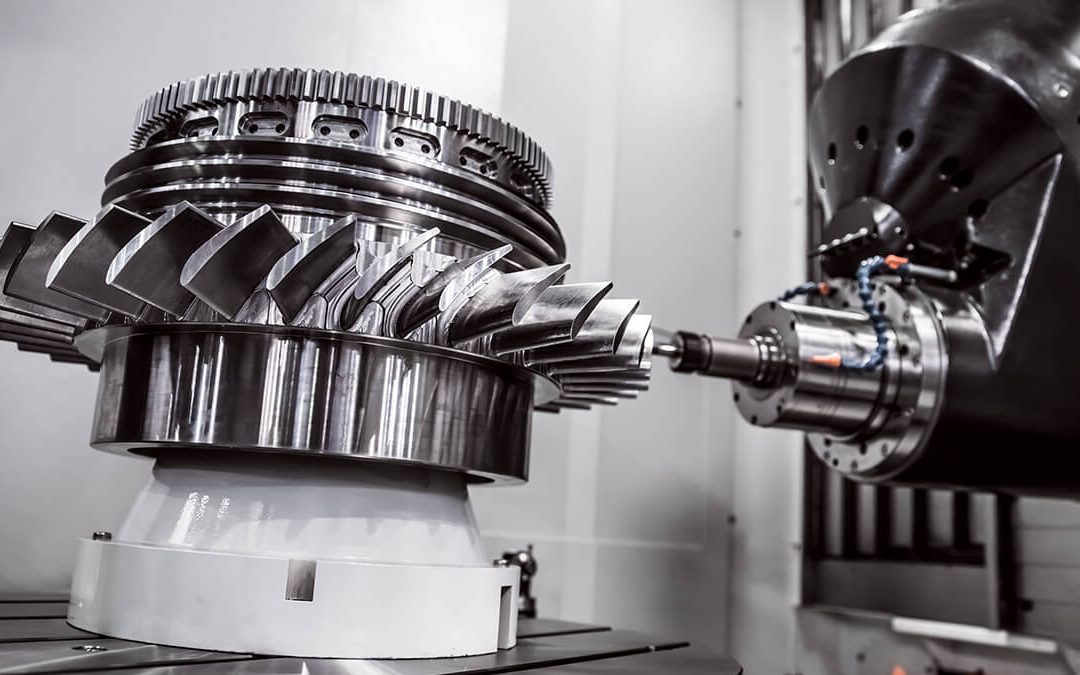

The dividing head is an accessory attached to a milling machine that allows for the precise division of workpieces into various angles. This tool is essential for tasks that require exact spacing and angles, such as gear cutting and polygon milling.

Components of a Dividing Head

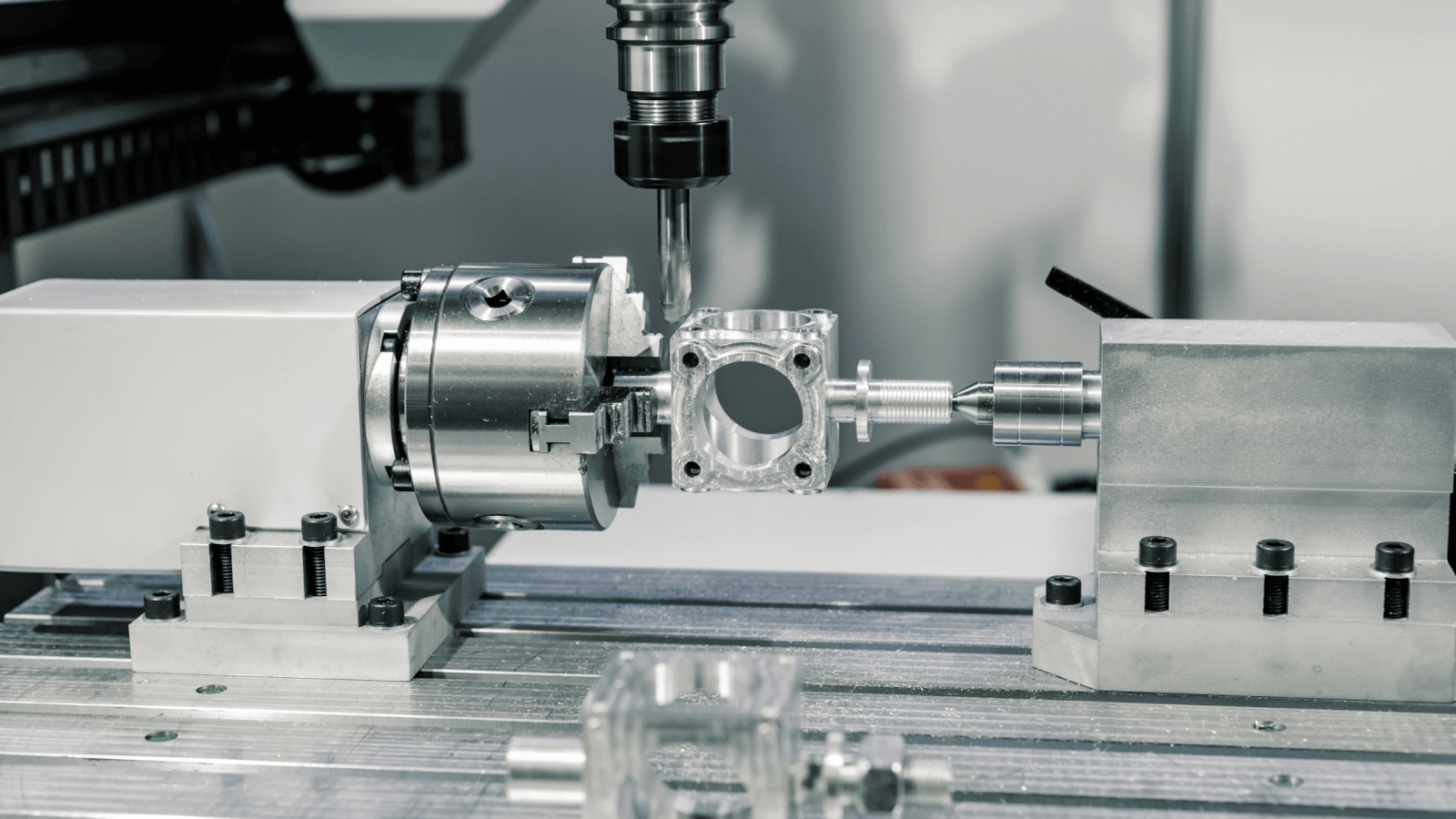

- Spindle – The rotating component that holds the workpiece.

- Indexing Plate – A plate with holes that enables accurate angle divisions.

- Sector Arms – Adjustable arms used to count the holes on the indexing plate.

- Worm Gear – A gear mechanism that enables precise rotation.

How Does a Dividing Head Work?

The dividing head works by using the worm gear to rotate the spindle through specific angles, as determined by the indexing plate. This allows for precise and repeatable positioning of the workpiece.

Types of Dividing Heads

Plain Dividing Head

This type is used for straightforward tasks and can be tilted to various angles.

Universal Dividing Head

This versatile head allows for more complex movements and is often used in advanced machining operations.

For those interested in high-speed gene analysis in milling or other applications, a universal dividing head provides the required precision.

Applications of Dividing Heads

- Gear Cutting

- Fluting

- Drilling Holes at Precise Angles

- Creating Complex Patterns

In the Manufacturing Industry

Dividing heads are invaluable in industries that demand high precision, such as aerospace and automotive sectors.

Advantages of Using a Dividing Head

The primary advantage is the unparalleled accuracy that a dividing head brings to a milling machine. It also allows for increased versatility in machining operations.

Cost-Effectiveness

Despite its complexity, investing in a dividing head can lead to cost savings due to improved precision and reduced material waste.

Maintenance and Care

Regular maintenance is crucial for the longevity of a dividing head. This includes proper lubrication, cleaning, and periodic inspections.

Future Trends

As technology advances, the capabilities of dividing heads are expected to grow. Innovations in automation and precision engineering will further enhance their utility.

Conclusion

In summary, the dividing head is a tremendous piece of technology that significantly boosts the capabilities of a milling machine. From simple tasks to complex machining operations, this tool is indispensable for achieving high precision.

Interested in more advanced technological applications? Check out our article on high-speed wafer polishing.

FAQs

1. What materials can be machined using a dividing head?

Dividing heads are versatile and can be used to machine a wide range of materials including metals, plastics, and composites.

2. Is a dividing head suitable for DIY projects?

While primarily designed for industrial use, some advanced DIY enthusiasts may find dividing heads useful for highly precise tasks.

3. How can I improve the accuracy of my dividing head?

Regular maintenance, proper calibration, and utilizing high-quality indexing plates can significantly improve the accuracy of your dividing head.

For more information on milling machines, you can visit this external resource.