Floor milling machines are essential in many industries, crucial for producing precision parts efficiently. Learning how to properly use a floor milling machine for maximum efficiency can greatly enhance productivity and quality. This guide aims to cover the essential steps, tips, and best practices for getting the most out of your floor milling machine.

Introduction to Floor Milling Machines

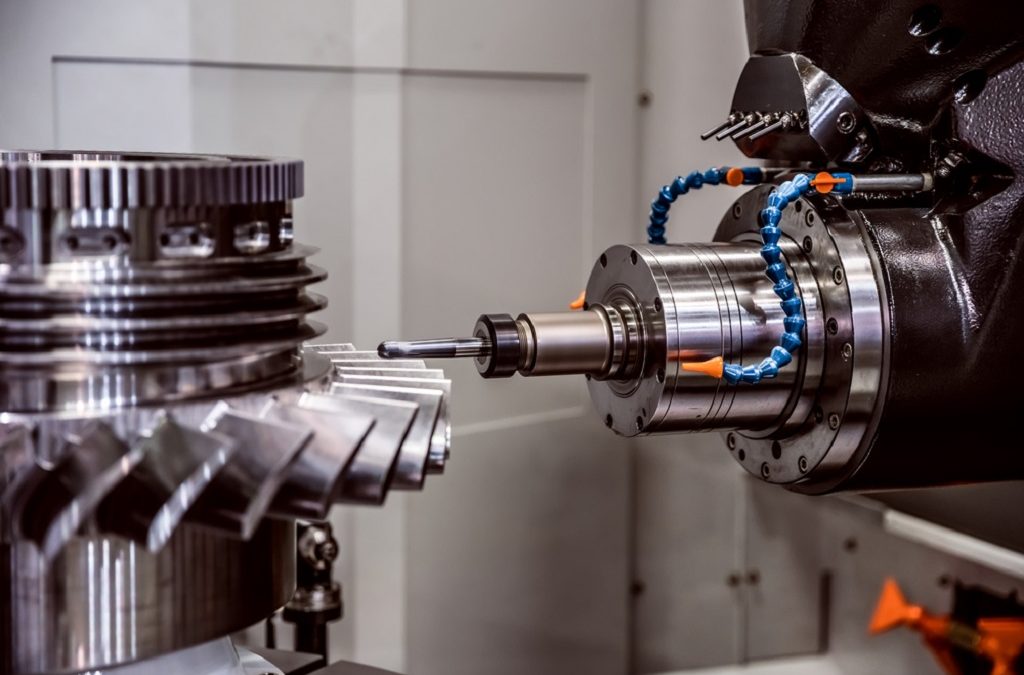

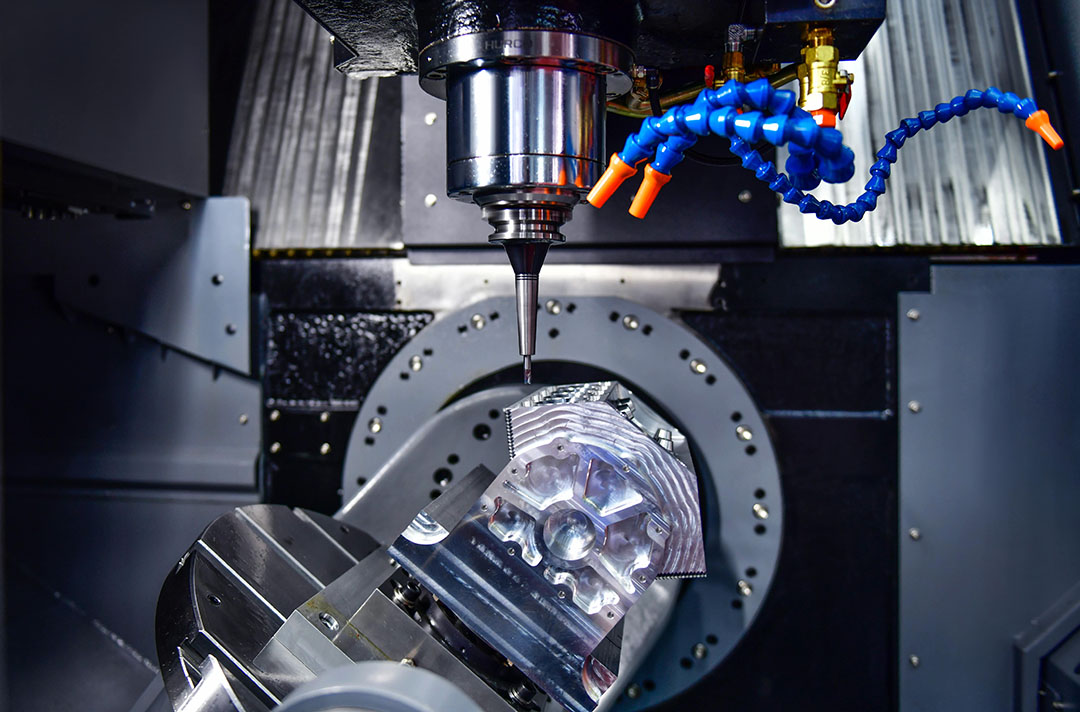

Before diving into the efficiency techniques, let’s understand what a floor milling machine is and its importance in the industry. These machines are used to shape and cut various materials, primarily metal, into specific designs. They are indispensable in manufacturing, automotive, and aerospace industries.

Components of a Floor Milling Machine

The Bed

The bed is the main structure that supports all other components. Ensuring that the bed is highly stable and durable is essential for precision milling.

The Spindle

The spindle holds the cutting tool and rotates at high speeds. Proper maintenance of the spindle ensures smooth cutting and longer machine life.

The Work Table

The work table is where the material is placed for milling. It must be rigid and properly aligned to avoid deviations in the milling process.

Pre-milling Checklist

Before starting your milling operations, there are several important steps to follow to ensure that the machine operates at peak efficiency.

Machine Inspection

Inspect the machine for any wear and tear. Replace or repair damaged parts immediately to prevent breakdowns.

Tool Selection

Choose the right tool for the job. The type of milling tool you select will significantly affect the quality and speed of your work.

Material Setup

Secure the work material firmly on the table. Use appropriate clamps and fixtures to ensure that it does not move during milling.

Milling Operation Techniques

Speed and Feed Rates

Selecting the proper speed and feed rates is crucial. You’ll need to adjust these settings based on the material and the type of milling operations you’re performing.

Depth of Cut

Setting the correct depth of cut is important for achieving the desired finish and avoiding tool overload. Typically, lighter cuts increase precision and tool life.

Coolants and Lubricants

Using appropriate coolants and lubricants can extend the life of your milling tools and improve surface finish. Always ensure that your machine’s coolant system is functioning properly.

Post-milling Procedures

After the milling operation, it’s essential to follow proper procedures to maintain machine efficiency.

Cleaning

Clean the machine thoroughly to remove any debris or metal shavings that could lead to wear and tear. Regular cleaning can significantly extend the life of your machine.

Inspection

Inspect the milled parts for accuracy and quality. Use precise measuring tools to ensure that they meet the required specifications.

Maintenance Tips for Extended Machine Life

Scheduled Maintenance

Regularly scheduled maintenance is crucial for the long-term efficiency of your milling machine. Follow the manufacturer’s guidelines for maintenance intervals and procedures.

Lubrication

Keep the machine properly lubricated. Pay attention to all moving parts and ensure that they are well-lubricated to avoid friction and wear.

Advanced Milling Techniques for Enhanced Efficiency

High-Speed Milling

For industries requiring extremely fine finishes and tolerance, high-speed milling techniques can be employed. These require specialized tools and setups.

Automation in Milling

Leveraging automation can take your milling efficiency to the next level. Automated setups reduce human error and increase production speed.

Common Mistakes to Avoid

Ignoring Maintenance

Neglecting regular maintenance is one of the biggest mistakes operators can make. Without it, machine parts can wear out quickly, leading to inefficiencies.

Incorrect Tool Usage

Using the wrong tool for the job can damage both the tool and the machine. Always ensure you are using the correct tool for your specific milling operation.

Read more about proper tool usage

Conclusion

Mastering how to properly use a floor milling machine for maximum efficiency requires a blend of knowledge, practice, and adherence to best practices. By understanding your machine, performing regular maintenance, and employing advanced techniques, you can significantly boost both productivity and quality in your operations.

Frequently Asked Questions (FAQ)

How often should I perform maintenance on my floor milling machine?

Regular maintenance should be performed as per the manufacturer’s recommendations, which often include daily, weekly, and monthly checklists.

What types of coolants are most effective in milling operations?

Water-soluble coolants are commonly used in milling operations due to their efficient cooling properties and ease of use.

Can automation improve the efficiency of my milling operations?

Yes, automation can significantly enhance efficiency by reducing human error and increasing operational speed. Advanced systems can help monitor and adjust various parameters in real-time.