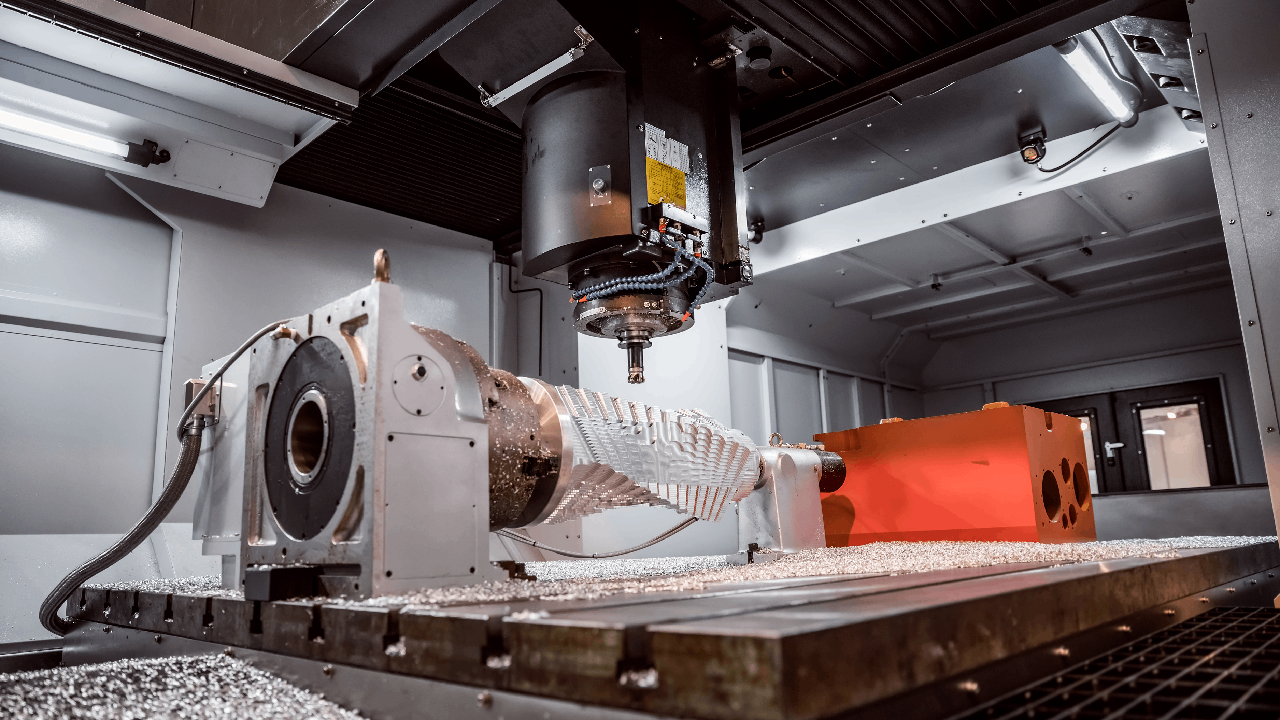

The sphere of manufacturing and machining is vast, intricate, and replete with numerous essential components. Central to this realm is the milling machine, a truly remarkable piece of technology. It’s here that the importance of workholding devices comes to light. For those pondering, what is the most common type of workholding device for a milling machine, this comprehensive guide will shed ample light on everything you need to know.

Introduction to Milling Machines

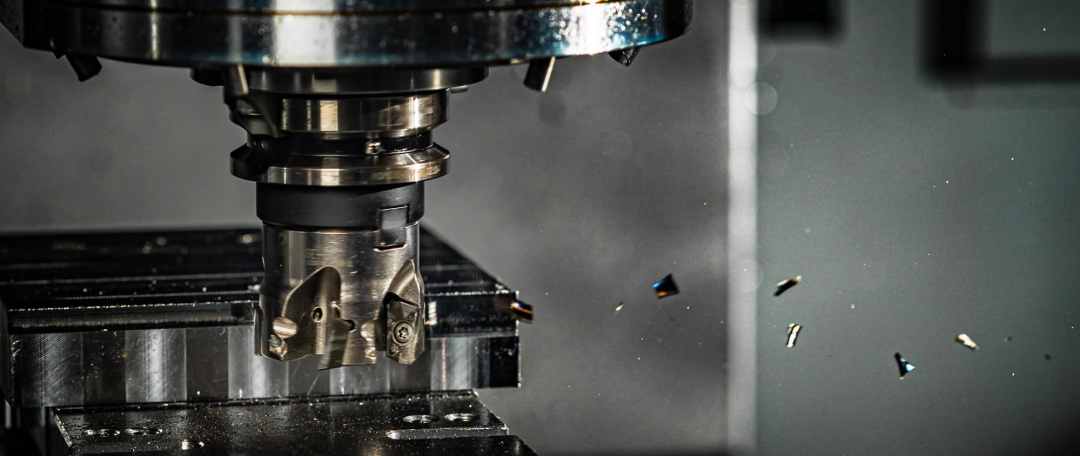

Milling machines play a pivotal role in the manufacturing sector. Designed to manufacture complex components with high precision, they work by removing material from a workpiece. The machine comprises various parts, but the focus here is primarily on the workholding device.

Understanding Workholding Devices

Before diving deep into the most common type of workholding device for a milling machine, its crucial to understand what workholding devices are. These tools secure the workpiece in place during machining, guaranteeing accuracy, safety, and efficiency.

Why are Workholding Devices Important?

The significance of workholding devices cannot be overstated. They ensure the workpiece remains stationary during operation, allowing for precision cutting, drilling, and forming. The absence of a robust workholding device could result in inaccurate fabrications and potential hazards.

Types of Workholding Devices

While there are various workholding devices, a few stand out due to their widespread use and versatility. Some popular devices include:

- Vises

- Clamps

- Fixtures

- Chucks

The Vise: Dominating the Workholding Scene

The title of the most common type of workholding device for a milling machine is almost unanimously awarded to the vise. Here’s why:

Simplicity and Efficiency

Vises are straightforward yet efficient devices. They consist of two jaws – one static and one movable. The workpiece is placed between these jaws and clamped securely.

Variety of Vises

There are several types of vises tailored to specific tasks. Some include:

- Machine Vises

- Drill Press Vises

- Angle Vises

- Precision Vises

Benefits of Using Vises

Vises offer numerous advantages:

- Enhanced precision and stability

- Reduced setup time

- Versatility across different tasks

Other Popular Workholding Devices

While the vise reigns supreme, several other workholding devices are essential in the milling world:

Clamps

Clamps are simple yet effective tools used to hold the workpiece down. They come in various shapes and sizes, each designed for specific tasks.

Fixtures

Fixtures are custom-designed equipment that ensures the workpiece remains secure. They provide superior accuracy, especially for repetitive tasks.

Chucks

Chucks, though more commonly associated with lathes, also play a role in milling. They offer a firm grip and are especially useful for cylindrical workpieces.

Choosing the Right Workholding Device

Selecting the appropriate workholding device is paramount. The nature of the task, workpiece material, and precision required all factor into the decision.

Conclusion:

The world of milling and workholding is vast and intricate. Vises remain the most prominent workholding device due to their simplicity, versatility, and efficiency. However, several other tools play crucial roles in ensuring the precision and safety of milling operations. Embracing the right workholding device can significantly enhance your milling endeavors.

FAQs

What is the primary function of a workholding device?

A workholding device secures the workpiece in place, ensuring stability, precision, and safety during machining operations.

Why is a vise considered the most common workholding device for milling machines?

Vises are widely used due to their simplicity, versatility, and ability to provide a firm grip on the workpiece, ensuring precise machining.

Are there different types of workholding devices?

Yes, popular workholding devices include vises, clamps, fixtures, and chucks. Each has its specific uses and advantages in machining operations.

For further information on milling machines, you can visit this comprehensive guide on milling machines. Additionally, our internal resources on advanced stroboscopic event detection and paint application inspection offer incredible insights into related technologies.

Published Date: 2024-10-01