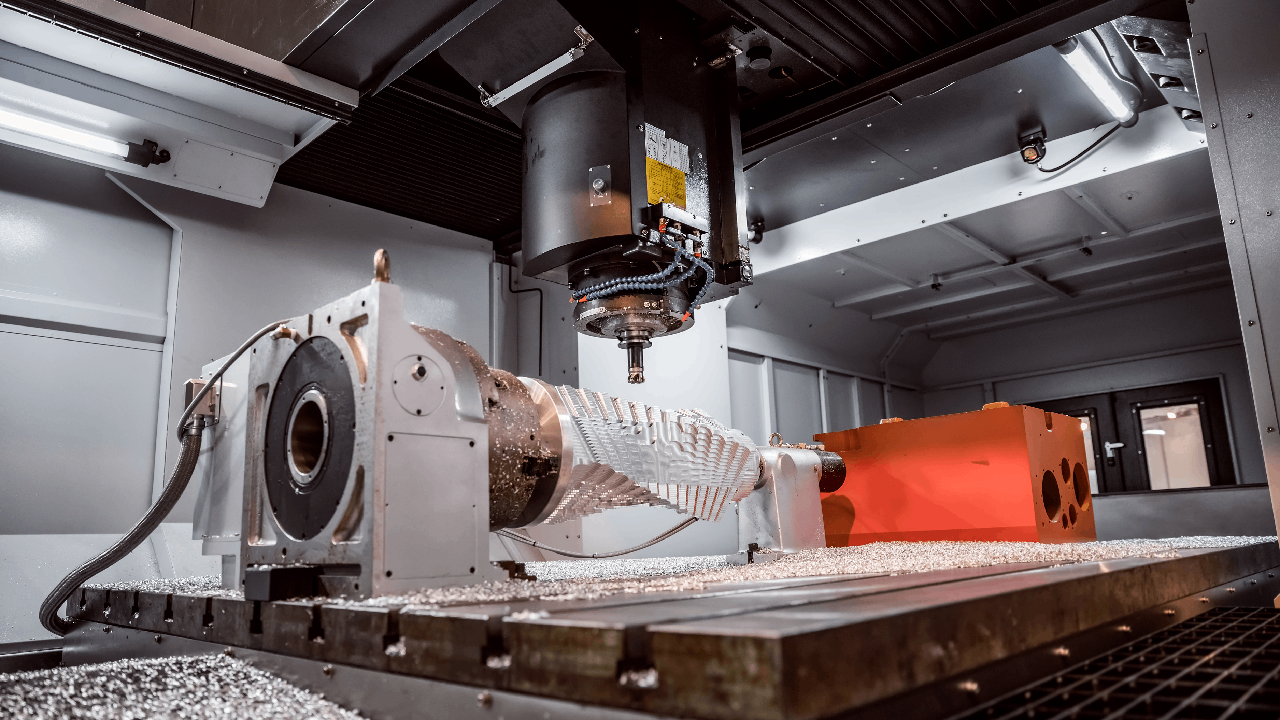

Welcome to an insightful journey into the **realm of fly cutters** and their role in **modern milling machines**. Whether you are an experienced Industry QA Professional or just beginning to delve into the **nuances of machining**, you might have come across the term fly cutter. So, what is a fly cutter on a milling machine?

A fly cutter is a single-point rotary cutting tool designed to produce a flat surface on a workpiece. This tool consists of a motorized spindle holding a cutter head with one or more tool bits. Unlike other **milling tools** that utilize multiple teeth for material removal, the **fly cutter** uses a single sharp cutting bit. This unique design allows the fly cutter to create large, smooth, circular cuts, essential for achieving precision in industrial applications.

The Basics of Fly Cutter Design

Fly cutters come in various shapes and sizes, mainly categorized based on their design and application. The typical components include:

- Spindle: The **spindle** acts as a motorized rotator that drives the cutter head.

- Cutter Head: The **cutter head** houses the tool bit and is adjustable to control the cutting radius.

- Tool Bit: The **tool bit** is a single-point cutting tool responsible for material removal.

Advantages and Applications of Fly Cutters

Precision and Surface Finish

Fly cutters are renowned for their ability to produce a fine surface finish. The **single-point cutting mechanism** ensures consistency across the workpiece, making them suitable for applications requiring high precision.

Cost-Effectiveness

Compared to multi-point cutting tools, **fly cutters** are cost-effective. They require fewer tool changes and less maintenance, translating into lower operational costs for industrial machining operations.

Versatility in Material

Fly cutters can efficiently machine various materials, including **aluminum, brass, and steel**. This versatility makes them indispensable in industries such as **aerospace, automotive, and electronics**.

Setting Up and Using a Fly Cutter

Choosing the Right Tool Bit

Selecting the appropriate tool bit is crucial for achieving the desired surface finish. Common tool bit materials include:

- High-Speed Steel (HSS): Suitable for general-purpose cutting.

- Carbide: Ideal for higher cutting speeds and harder materials.

- Ceramics: Used for the highest cutting speeds and exotic materials.

For more details on milling, you can visit this resource.

Mounting the Fly Cutter

Securely mounting the fly cutter is essential for safety and precision. Ensure the cutter head is properly fastened to the spindle and the workpiece is securely clamped on the milling machine table.

Adjusting Cutting Parameters

Adjust the cutting speed and feed rate according to the material and desired finish. Lower speeds are typically used for harder materials, while higher speeds work well for softer ones.

Maintenance and Safety Tips for Using Fly Cutters

Regular Inspection

Regularly inspect the cutter head and tool bit for wear and damage. Replace or sharpen the tool bit as needed to maintain cutting efficiency.

Ensuring Proper Lubrication

Adequate lubrication is vital for reducing friction and extending the tools lifespan. Use appropriate cutting fluids based on the material being machined.

Adherence to Safety Protocols

Always wear appropriate personal protective equipment (PPE) when operating a milling machine. Follow all safety guidelines to prevent accidents and injuries.

Case Studies: Fly Cutters in Industrial Applications

Fly cutters have been pivotal in numerous industrial applications. Let’s explore a couple of real-world scenarios:

Aerospace Industry

In the aerospace industry, fly cutters are utilized for machining precise components like turbine blades and aircraft fuselages. The tool’s ability to achieve a fine finish ensures that the critical parts meet stringent quality standards.

Automotive Manufacturing

Automotive manufacturing relies on fly cutters for producing engine parts and transmission components. The versatility in machining various metals with high precision helps in maintaining the quality and performance of the vehicles.

FAQs

What materials can be machined using a fly cutter?

Fly cutters can machine materials such as **aluminum, brass, and various types of steel**. The tools versatility makes it suitable for different industrial applications.

How do I choose the right tool bit for my fly cutter?

Select the tool bit based on the material being machined and the desired cutting speed. Common materials for tool bits include **high-speed steel, carbide, and ceramics**.

What are the key advantages of using a fly cutter on a milling machine?

Fly cutters offer benefits like **cost-effectiveness, versatility, and the ability to produce a fine surface finish**. They are crucial for applications requiring precision machining.

For further reading on the topic, you can refer to the Britannica article.