In the world of milling machines, the term indexing signifies a critical process that ensures precision in machining operations. But what is indexing in milling machine? This article delves into the depths of indexing, exploring its significance, various methods, and applications in the industry.

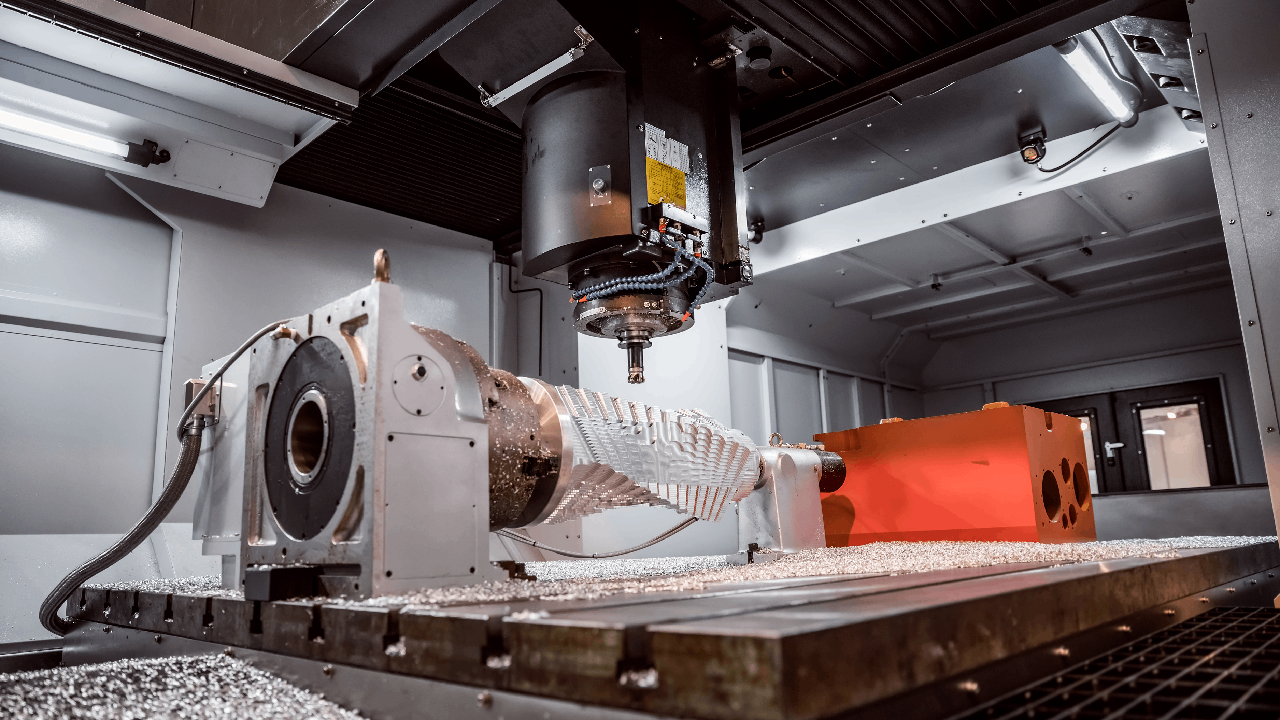

Introduction to Milling Machines

Milling machines are vital tools in the manufacturing industry. They facilitate the process of shaping hard materials, predominantly metals, by removing excess material. This is achieved using rotary cutters, which perform various operations like cutting, drilling, and shaping.

The Concept of Indexing

Definition and Importance

Indexing is a process of evenly dividing a circular or linear workpiece into equal parts. This ensures accurate machining of parts, thereby maintaining consistency and precision across the manufacturing process. In the context of milling machines, indexing is indispensable for machining components like gears, slots, and flutes.

Historical Background

The concept of indexing dates back to ancient times when craftspeople used rudimentary tools to achieve precision. Over the centuries, this process has evolved, integrating advanced technology and automation, making modern-day indexing a sophisticated and accurate process.

Types of Indexing Methods

Simple Indexing

Simple indexing is the most basic form of indexing and is used for projects requiring minimal accuracy. It involves using a simple index plate and a crank handle. This method is straightforward but limited in terms of precision.

Compound Indexing

Compound indexing is more advanced than simple indexing. It uses multiple index plates and complex calculations to achieve higher accuracy. This method is beneficial for intricate tasks that require precise divisions.

Direct Indexing

Direct indexing employs a direct indexing plate attached to a spindle. This method allows for quick and easy indexing but is generally suitable for less complex operations.

Differential Indexing

Differential indexing is used for operations that require high precision. It involves the use of gear trains and two index plates, allowing for very fine adjustments. This method is ideal for complicated tasks involving finer divisions.

Angular Indexing

Angular indexing is employed when components need to be divided at specific angles rather than equal divisions. This method uses angular scales and vernier scales for precise measurement.

Components of an Indexing Machine

Index Plate

The index plate is a circular disk with a series of holes arranged in concentric circles. It is the primary tool used for simple and compound indexing.

Sector Arms

Sector arms are adjustable arms that help in setting the required number of divisions on the index plate.

Index Crank

The index crank is used to rotate the index plate to the desired position.

Spindle

The spindle holds the workpiece and is rotated by the index crank to achieve the required divisions.

Worm and Worm Wheel

The worm and worm wheel mechanism is used in differential indexing to achieve high precision.

Applications of Indexing in the Industry

Gear Cutting

Indexing is widely used in gear cutting. It ensures that gear teeth are evenly spaced, which is crucial for the gear’s performance.

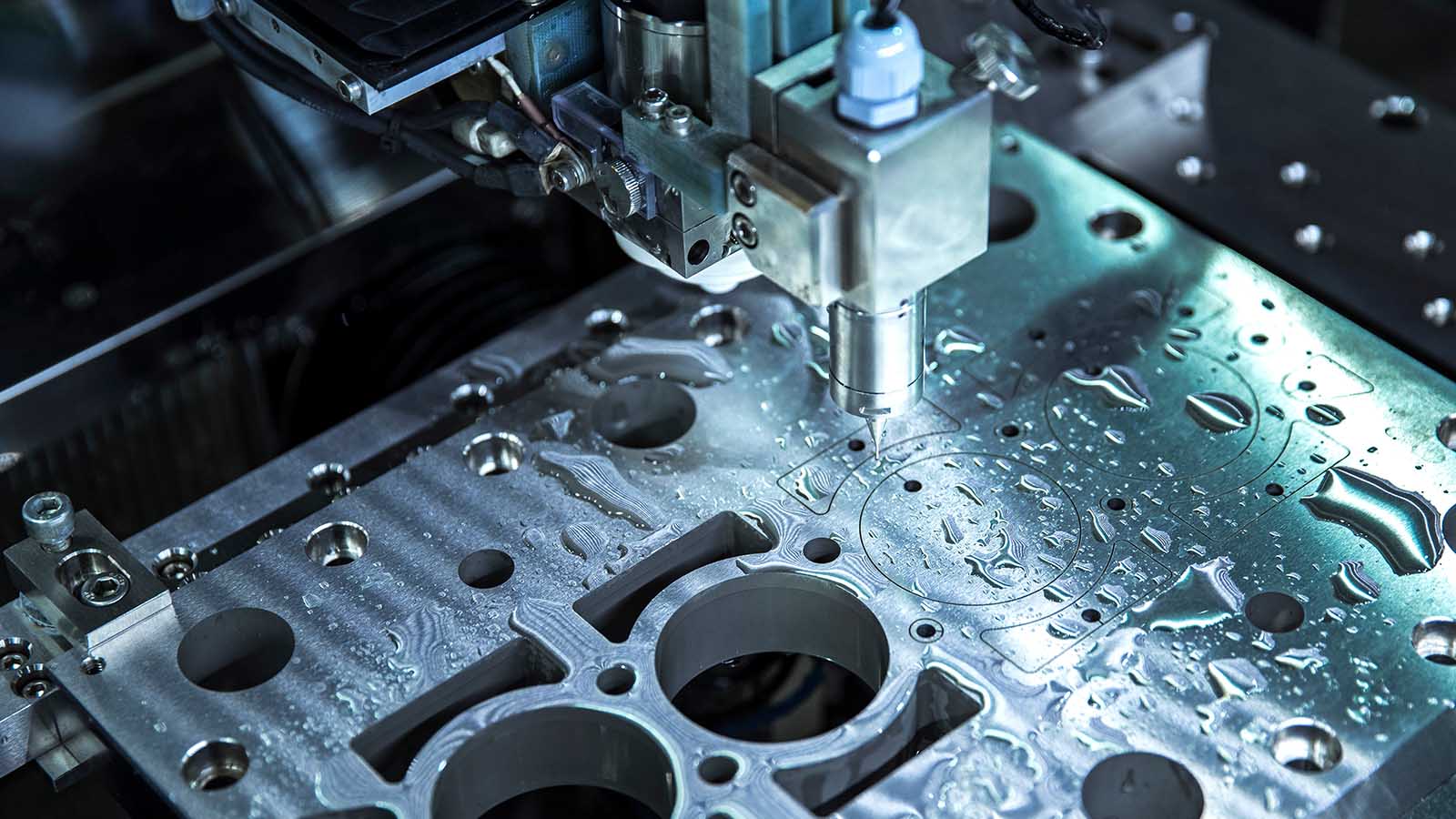

Slotting

Indexing is also used for creating slots on various components. This process requires high precision to ensure the slots are evenly spaced.

Drilling

Indexing is used in drilling operations to create evenly spaced holes on a workpiece. This is essential for components like flanges and sprockets.

Fluting

Indexing is crucial for creating flutes on tools like drills and end mills. This ensures that the flutes are evenly spaced and accurately positioned.

Advantages of Indexing

Precision

Indexing ensures high precision in machining operations, which is crucial for the performance and longevity of the components.

Efficiency

Indexing increases the efficiency of the manufacturing process by ensuring that components are machined accurately and quickly.

Consistency

Indexing ensures consistency in the manufacturing process, which is crucial for mass production.

Challenges in Indexing

Complexity

Indexing can be complex, requiring skilled operators and precise calculations.

Cost

Indexing can be costly, especially for precision indexing methods that require advanced equipment.

Future of Indexing Technology

The future of indexing technology looks promising with advancements in automation and artificial intelligence. These technologies are set to revolutionize indexing, making it more accurate, efficient, and cost-effective.

Conclusion

Indexing is a critical process in the manufacturing industry. It ensures precision, efficiency, and consistency in machining operations. Understanding the various methods of indexing and their applications can help industry professionals choose the right method for their specific needs.

Frequently Asked Questions (FAQs)

What is the main purpose of indexing in milling machines?

The main purpose of indexing in milling machines is to divide a workpiece into equal parts for precise machining operations.

Which method of indexing is used for high precision?

Differential indexing is used for high precision operations. It involves the use of gear trains and two index plates.

What are the main components of an indexing machine?

The main components of an indexing machine include the index plate, sector arms, index crank, spindle, and worm and worm wheel mechanism.