The drill press is a piece of machinery known for its precision and power in drilling holes into various materials. For anyone working in woodworking, metalworking, or manufacturing, understanding what does a drill press do is critical. Its popularity stems from its versatility and the quality of the results it delivers.

The Basics: Understanding Drill Presses

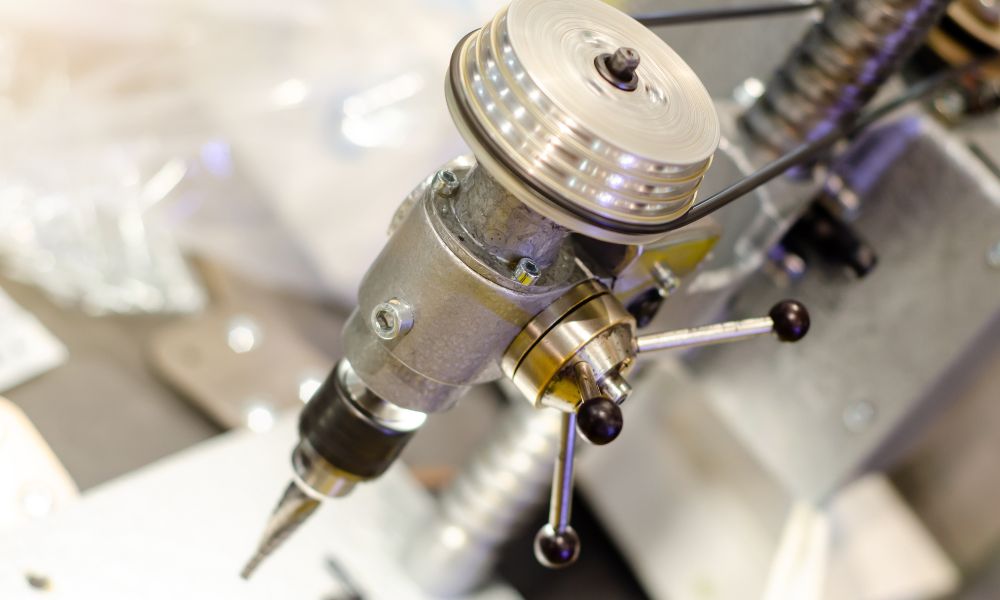

A drill press operates by rotating drill bits of different sizes and shapes into a fixed position, allowing users to make consistent and accurate holes. This machine is an essential tool for many professionals due to its efficiency and ease of use.

Why You Need a Drill Press

There are numerous reasons to understand the importance of drill presses in industrial operations. These machines not only save time but also ensure safety and precision, which is paramount in any manufacturing environment. Efficient hole drilling is crucial for assembling components in both metal and wood industries.

Types of Drill Presses

Bench Drill Press

A bench drill press is mountable on a workbench and is suitable for smaller tasks. It is ideal for home workshops or small businesses.

Floor Drill Press

A floor drill press offers more power and is best used in industrial settings where heavy-duty drilling is required. This type is often favored for its ability to handle larger workpieces and demanding tasks.

Key Features of a Drill Press

Understanding the key features of a drill press can help users make the most out of this terrific technology. These features include:

- Variable Speed Control – Essential for handling different materials.

- Depth Stop – Ensures precise depth drilling.

- Table Adjustments – Allows for versatility in drilling positions.

- Laser Guide – Improves accuracy.

Applications in Various Industries

Woodworking

In woodworking, a drill press is used to create clean, precise holes for dowels, screws, and other fasteners. Its an invaluable tool for creating intricate patterns and designs.

Metalworking

In metalworking, the drill press is essential for boring holes into metal parts. It ensures uniformity and precision, which is critical for the integrity of the workpiece.

How to Operate a Drill Press

Operating a drill press involves several steps: securing the material, selecting the correct drill bit, setting the speed, and using the feed handle to drill the hole. Safety precautions are necessary to avoid accidents.

Buying a Drill Press

When buying a drill press, consider factors like the type of work youll be doing, the drill presss power, and its key features. Reading reviews and consulting professionals can help in making an informed decision.

Maintenance Tips for Drill Presses

Proper maintenance of a drill press ensures its longevity. Regularly check for wear and tear, keep it clean, and lubricate moving parts. Doing so will keep the machine running smoothly.

FAQs

What materials can a drill press handle?

A drill press can handle a variety of materials, including wood, metal, plastic, and composites.

Is a drill press suitable for home use?

Yes, bench drill presses are perfect for home workshops and small businesses. They offer precision and are compact.

What safety measures should be taken while using a drill press?

Always wear safety goggles, secure the material being drilled, and avoid loose clothing that could get caught in the machine.

Conclusion

Understanding what does a drill press do is crucial for maximizing its potential in any industrial or workshop setting. This approved technology not only enhances productivity but also ensures the precision and quality of work. Whether in woodworking, metalworking, or other industries, the drill press remains a vital tool that delivers tremendous value. To delve deeper into the benefits and operational tips, you may find this guide helpful.