In today’s rapidly advancing industrial landscape, ensuring the reliability and safety of equipment is paramount. One of the most effective methods for achieving this is through vibration frequency analysis in inspection tools. This technique allows professionals to detect potential issues early, minimizing downtime and maintenance costs. In this article, we will delve into the intricacies of this method and its significance in quality assurance.

Understanding Vibration Frequency Analysis

Vibration frequency analysis is a diagnostic process used to monitor and analyze the vibrations of machines and equipment. By measuring these vibrations, inspectors can identify irregularities or deviations from normal operating conditions, indicating potential faults or failures. This process is crucial for preventive maintenance and plays a significant role in extending the lifespan of machinery.

The Importance of Inspection Tools

Inspection tools equipped with vibration frequency analysis capabilities are essential for industry professionals. These tools provide precise measurements, enabling experts to make informed decisions regarding maintenance and repairs. Accurate data collection is vital in preventing unexpected breakdowns and ensuring the smooth operation of industrial equipment.

Applications in Various Industries

The application of vibration frequency analysis spans across multiple industries, including manufacturing, automotive, aerospace, and energy. Each sector relies on this technology to maintain the efficiency and reliability of their operations. For instance, in the manufacturing industry, detecting anomalies in machinery early can prevent costly production halts.

Tools and Techniques

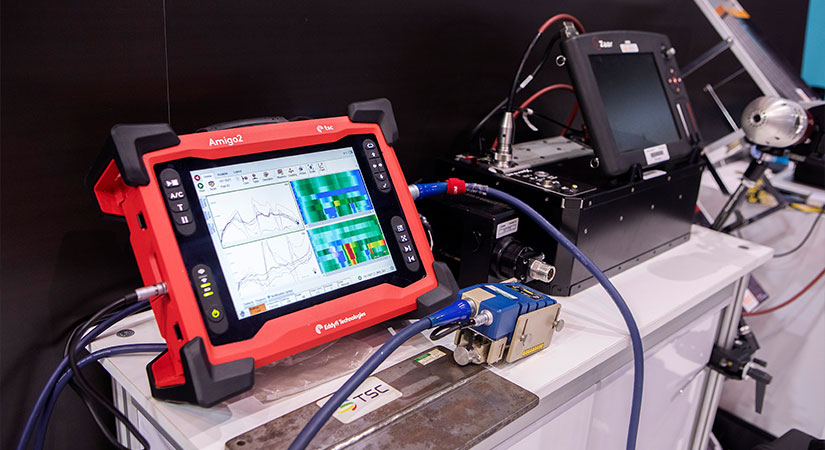

There are various inspection tools available that utilize vibration frequency analysis. These include accelerometers, velocity sensors, and displacement sensors, each serving specific purposes. The choice of tool depends on the type of machinery and the specific requirements of the inspection process.

Key Factors in Determining Frequency

Benefits of Vibration Frequency Analysis

The benefits of employing vibration frequency analysis in inspection tools are manifold. Not only does it help in early fault detection, but it also aids in optimizing maintenance schedules. This proactive approach reduces the likelihood of unexpected failures, enhancing overall productivity and reducing operational costs.

Cost-Effectiveness

By identifying potential issues before they escalate, companies can save significantly on repair and replacement costs. The initial investment in inspection tools equipped with vibration frequency analysis capabilities is often outweighed by the long-term savings achieved through reduced downtime and maintenance expenses.

Improved Safety

Safety is a critical concern in any industrial setting. By ensuring that machinery operates within safe parameters, vibration frequency analysis contributes to a safer working environment. This, in turn, protects employees and reduces the risk of accidents or injuries.

Optimal Frequency for Detection

Challenges and Considerations

Despite its advantages, implementing vibration frequency analysis is not without challenges. It requires skilled personnel to interpret the data accurately and make informed decisions. Additionally, the initial setup and calibration of inspection tools can be complex and time-consuming.

Training and Expertise

To fully leverage the benefits of vibration frequency analysis, companies must invest in training their workforce. This ensures that personnel are equipped with the necessary skills to operate the tools effectively and interpret the results accurately.

The Future of Vibration Frequency Analysis

The future of vibration frequency analysis looks promising, with advancements in technology paving the way for more sophisticated and efficient inspection tools. Innovations such as wireless sensors and real-time data analytics are set to revolutionize the field, making it more accessible and effective for industry professionals.

Emerging Trends

One of the emerging trends in vibration frequency analysis is the integration of artificial intelligence and machine learning. These technologies enable more precise and predictive analysis, allowing for even earlier detection of potential issues.

Conclusion

In conclusion, vibration frequency analysis in inspection tools is an invaluable asset for quality assurance professionals. By providing early detection of faults and optimizing maintenance schedules, it enhances productivity, safety, and cost-effectiveness in various industries. As technology continues to evolve, the capabilities of these tools will only expand, offering even greater benefits for those who embrace them.

FAQs

What is vibration frequency analysis?

Vibration frequency analysis is a diagnostic method used to monitor and analyze the vibrations of machinery to detect potential faults or failures.

Why is it important in inspection tools?

It is crucial because it provides precise data for early fault detection, optimizing maintenance schedules, and ensuring the reliability of industrial equipment.

What industries benefit from this technology?

Industries such as manufacturing, automotive, aerospace, and energy heavily rely on vibration frequency analysis to maintain operational efficiency and safety.

This article contains affiliate links. We may earn a commission at no extra cost to you.