In the realm of power generation, the term synchronization plays a pivotal role, especially when it comes to synchronization in power plant inspections. This process ensures that inspections are conducted efficiently and effectively, minimizing downtime and optimizing operational performance. For industry QA professionals, understanding the intricacies of synchronization is essential to maintaining the integrity and safety of power plants.

The Significance of Synchronization in Power Plants

Synchronization is crucial in power plants as it ensures that all components operate in harmony. This is not only vital for the plant’s efficiency but also for its safety. In inspections, synchronization helps in coordinating multiple inspection activities, ensuring that they do not interfere with one another and that the plant continues to operate smoothly.

Benefits of Synchronization

One of the primary benefits of synchronization in inspections is the reduction of downtime. By ensuring that inspections are conducted in a coordinated manner, power plants can continue to operate while inspections are ongoing, thus minimizing the impact on power generation. Moreover, synchronized inspections can identify potential issues before they lead to more significant problems, thereby enhancing the plant’s reliability and safety.

Challenges in Achieving Synchronization

While synchronization offers numerous benefits, achieving it is not without challenges. One major challenge is the coordination of different inspection teams and tools. Each team may have its own schedules and priorities, which can lead to conflicts. Furthermore, the integration of new technologies and methodologies into existing inspection processes can be complex and time-consuming.

Technologies Facilitating Synchronization

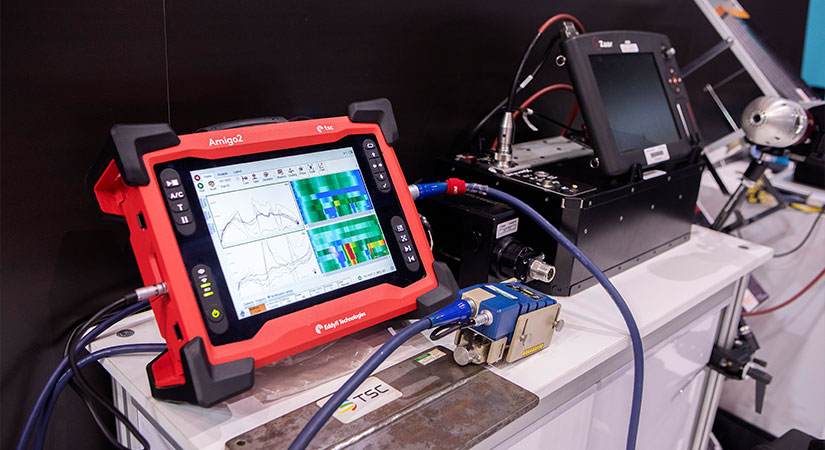

Several technologies have been developed to facilitate synchronization in power plant inspections. These include advanced scheduling software, real-time monitoring systems, and data analytics tools. Such technologies enable inspection teams to coordinate their activities more effectively, ensuring that inspections are conducted seamlessly.

Role of Advanced Scheduling Software

Advanced scheduling software is a key component in achieving synchronization. It allows inspection teams to plan and coordinate their activities in advance, taking into account the availability of resources and the operational schedule of the plant. This ensures that inspections are conducted at the most opportune times, minimizing disruptions to power generation.

Real-time Monitoring Systems

Real-time monitoring systems provide inspection teams with up-to-date information about the plant’s operations. This enables them to make informed decisions about when and how to conduct inspections, ensuring that they are carried out efficiently and effectively. Additionally, these systems can alert teams to any issues that may arise during inspections, allowing them to address them promptly.

Implementing Synchronization in Power Plant Inspections

Implementing synchronization in power plant inspections requires a strategic approach. This involves not only the adoption of new technologies but also a change in the organizational culture. Inspection teams must be willing to collaborate and share information, and plant operators must be open to integrating new methodologies into their existing processes.

Steps for Successful Implementation

- Conduct a thorough assessment of current inspection processes to identify areas for improvement.

- Invest in advanced technologies that facilitate synchronization, such as scheduling software and monitoring systems.

- Foster a culture of collaboration among inspection teams and plant operators.

- Provide training and support to ensure that all stakeholders are familiar with the new technologies and methodologies.

Measuring the Success of Synchronization

To determine the success of synchronization efforts, it is essential to establish key performance indicators (KPIs). These may include metrics such as the reduction in inspection time, the number of identified issues, and the overall impact on plant operations. By regularly monitoring these KPIs, power plants can assess the effectiveness of their synchronization efforts and make necessary adjustments.

Future Trends in Synchronization

As technology continues to evolve, new trends are emerging that will further enhance synchronization in power plant inspections. These include the use of artificial intelligence and machine learning to optimize inspection schedules and the integration of IoT devices to provide real-time data on plant operations.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning are poised to revolutionize power plant inspections by enabling more accurate predictions and optimizing inspection schedules. These technologies can analyze vast amounts of data to identify patterns and trends, allowing inspection teams to focus on areas that require the most attention.

Integration of IoT Devices

The integration of IoT devices into power plants provides inspection teams with real-time data on various aspects of plant operations. This enables them to make more informed decisions about when and how to conduct inspections, ensuring that they are carried out effectively and efficiently.

Conclusion

In conclusion, synchronization in power plant inspections is a vital component of modern power plant operations. By ensuring that inspections are conducted in a coordinated manner, power plants can minimize downtime and enhance their overall efficiency and safety. As new technologies continue to emerge, the potential for further improvements in synchronization is immense, promising even greater benefits for the industry.

FAQs

Why is synchronization important in power plant inspections?

Synchronization is important because it ensures that all inspection activities are coordinated, minimizing downtime and enhancing operational efficiency.

What technologies are used to facilitate synchronization?

Technologies such as advanced scheduling software, real-time monitoring systems, and data analytics tools are used to facilitate synchronization in power plant inspections.

How can power plants implement synchronization effectively?

Power plants can implement synchronization effectively by investing in advanced technologies, fostering a culture of collaboration, and providing training and support to all stakeholders.

This article contains affiliate links. We may earn a commission at no extra cost to you.