In today’s rapidly advancing technological landscape, the frequency role in autonomous inspection systems has become increasingly significant. As industries strive for precision and efficiency, understanding the nuances of frequency in these systems is crucial. Whether it’s in the automotive, manufacturing, or energy sectors, frequency analysis plays a vital part in ensuring seamless and accurate inspections. This article delves into the multifaceted role of frequency in autonomous inspection systems, shedding light on its importance and applications.

What Are Autonomous Inspection Systems?

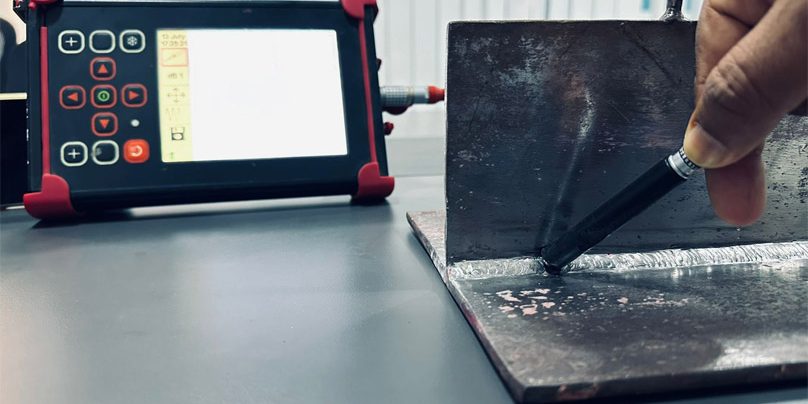

Autonomous inspection systems are advanced technologies designed to perform inspections without human intervention. These systems leverage a combination of sensors, cameras, and algorithms to detect defects, measure dimensions, and ensure quality compliance. The integration of frequency analysis in these systems enhances their capabilities, enabling them to perform more accurate and reliable inspections.

The Importance of Frequency in Inspection Systems

The role of frequency in inspection systems cannot be overstated. By analyzing frequency data, these systems can detect subtle changes in materials and components that might go unnoticed by the naked eye. This capability is particularly valuable in industries where precision and reliability are paramount. For more insights on how to determine inspection frequency, you can visit this guide on inspection frequency.

How Frequency Analysis Works

Frequency analysis is the process of examining the frequency of signals or data points to identify patterns or anomalies. In the context of autonomous inspection systems, this involves analyzing the frequency of vibrations, sound waves, or other signals emitted by the equipment or materials being inspected. This analysis helps to pinpoint areas of concern or potential failure.

Applications in Different Industries

From automotive to aerospace, the applications of frequency analysis in inspection systems are vast and varied. In the automotive industry, for example, frequency analysis can be used to detect inconsistencies in engine vibrations, which could indicate potential issues. Similarly, in the aerospace sector, frequency analysis helps to ensure the structural integrity of aircraft components.

Challenges and Solutions

Despite its many benefits, integrating frequency analysis into autonomous inspection systems presents several challenges. These include the need for advanced algorithms, high-quality sensors, and effective data interpretation. However, ongoing advancements in technology continue to address these challenges, making frequency analysis an indispensable tool in modern inspection systems.

Advancements in Frequency Analysis Technology

Recent developments in sensor technology and data processing have significantly enhanced the capabilities of frequency analysis in inspection systems. These advancements have led to more accurate and efficient inspections, ultimately improving product quality and reliability.

Future Prospects

As technology continues to evolve, the role of frequency analysis in autonomous inspection systems is expected to grow. Future innovations may include the integration of artificial intelligence and machine learning, further enhancing the accuracy and efficiency of inspections.

Conclusion

In conclusion, the frequency role in autonomous inspection systems is a critical component in ensuring the accuracy and reliability of inspections across various industries. By leveraging frequency analysis, businesses can enhance their inspection processes, ultimately leading to improved product quality and customer satisfaction. For more information on frequency in inspection tools, check out this resource on frequency in inspection tools.

Frequently Asked Questions

What is frequency analysis in inspection systems?

Frequency analysis in inspection systems involves examining the frequency of signals to identify patterns or anomalies, helping to detect potential issues in materials or components.

Why is frequency important in autonomous inspections?

Frequency is important in autonomous inspections because it allows for the detection of subtle changes that might not be visible to the naked eye, ensuring more accurate and reliable inspections.

What are the future prospects of frequency analysis in inspection systems?

The future prospects of frequency analysis in inspection systems include the integration of artificial intelligence and machine learning, which will further enhance the accuracy and efficiency of inspections.

This article contains affiliate links. We may earn a commission at no extra cost to you.