In the fast-evolving world of printing, maintaining high-quality standards is crucial. One of the significant challenges faced by industry professionals is detecting dye defects in printing. Identifying these defects early in the production process can save time, reduce waste, and enhance the overall quality of the printed materials.

Understanding Dye Defects

Dye defects refer to any inconsistencies or errors in the coloration of printed materials. These defects can arise from various factors, including equipment malfunctions, improper ink mixtures, and environmental conditions. Recognizing these defects is essential to ensure the final product meets the required standards.

Types of Dye Defects

Color Variations

One common type of dye defect is color variation. This occurs when the color of the print does not match the intended design. It can be due to incorrect ink formulation or inconsistencies in the printing process.

Streaks and Lines

Streaks and lines are another frequent issue. These appear as unintended marks on the print surface and often result from dirty print heads or dried ink.

Uneven Coverage

Uneven coverage of ink can lead to areas where the dye is either too intense or too light. This can be caused by improper pressure settings or incorrect ink viscosity.

Importance of Detecting Dye Defects Early

Early detection of dye defects is crucial for maintaining quality control in the printing process. Identifying issues early allows for timely corrections, preventing large-scale production errors.

Techniques for Detecting Dye Defects

Visual Inspection

Visual inspection is one of the simplest methods for detecting dye defects. Trained professionals can identify issues by examining prints under controlled lighting conditions.

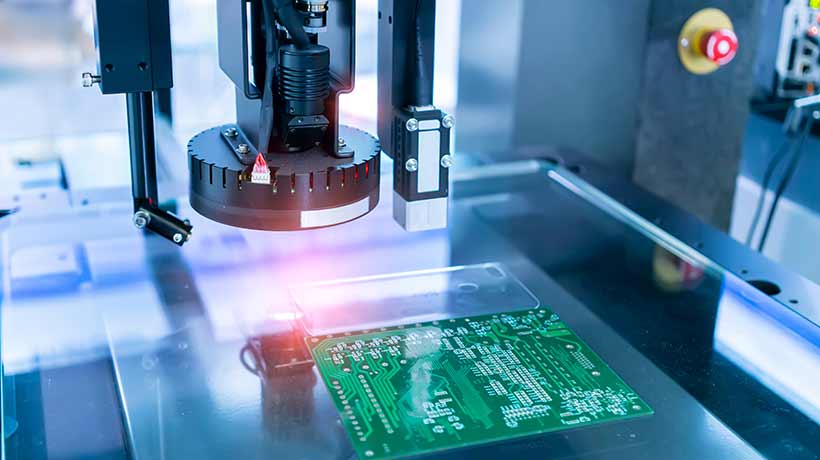

Automated Inspection Systems

Automated systems use advanced cameras and software to detect defects. These systems can identify even minor inconsistencies that might be missed by the human eye.

Stroboscopic Inspection

Stroboscopic inspection involves using stroboscope lights to detect defects in rapidly moving print materials. This method allows for real-time inspection without slowing down the production line.

Implementing Quality Control Measures

Implementing effective quality control measures is essential for minimizing dye defects. Regular maintenance of equipment, proper training for staff, and investing in automated inspection systems can significantly reduce the occurrence of defects.

Benefits of Quality Assurance in Printing

Ensuring quality in printing not only enhances the final product but also builds trust with clients and reduces costs associated with reprinting and waste.

Challenges in Detecting Dye Defects

Despite advancements in technology, detecting dye defects can still be challenging. Variability in materials, environmental factors, and complex designs can all contribute to difficulties in maintaining consistent quality.

Future Trends in Dye Defect Detection

As technology continues to advance, the future of dye defect detection looks promising. Innovations in artificial intelligence and machine learning are expected to play a significant role in improving the accuracy and efficiency of defect detection systems.

Conclusion

In conclusion, detecting dye defects in printing is a critical aspect of maintaining high-quality standards in the industry. By understanding the types of defects, implementing effective detection techniques, and investing in quality control measures, printing professionals can ensure their products meet the highest standards of excellence.

Related Topics

FAQs

What are the common causes of dye defects in printing?

Common causes include equipment malfunctions, incorrect ink formulations, and environmental factors affecting the printing process.

How can automated systems help in detecting dye defects?

Automated systems use advanced cameras and software to identify even minor inconsistencies, offering greater accuracy than manual inspection.

What role does stroboscopic inspection play in quality control?

Stroboscopic inspection allows for real-time detection of defects in rapidly moving print materials, enhancing the efficiency of the quality control process.

This article contains affiliate links. We may earn a commission at no extra cost to you.