In today’s fast-paced manufacturing world, the detection of missing parts is crucial for ensuring product quality and customer satisfaction. As industries strive for greater efficiency, the need for accurate and reliable systems to identify missing components in assemblies has become more important than ever. This article explores the various methods and technologies employed in the detection of missing parts, providing insights for industry QA professionals who are keen on maintaining high-quality standards.

Understanding the Importance of Missing Parts Detection

The presence of missing parts in a product can lead to significant issues, ranging from diminished functionality to complete product failure. For businesses, this translates to costly recalls, damaged reputation, and loss of customer trust. Therefore, implementing effective systems for the detection of missing parts is essential for maintaining product integrity and customer satisfaction.

Common Causes of Missing Parts in Manufacturing

Before diving into detection methods, it’s crucial to understand the common causes of missing parts in manufacturing:

Human Error

Despite the automation in manufacturing processes, human intervention is often necessary. Errors during manual assembly or inspection can lead to missing parts.

Machine Malfunctions

Equipment breakdowns or malfunctions can result in incomplete assemblies, leading to missing components going unnoticed.

Material Handling Issues

Problems during the transportation and storage of parts can lead to losses or misplacement, contributing to missing parts in the final product.

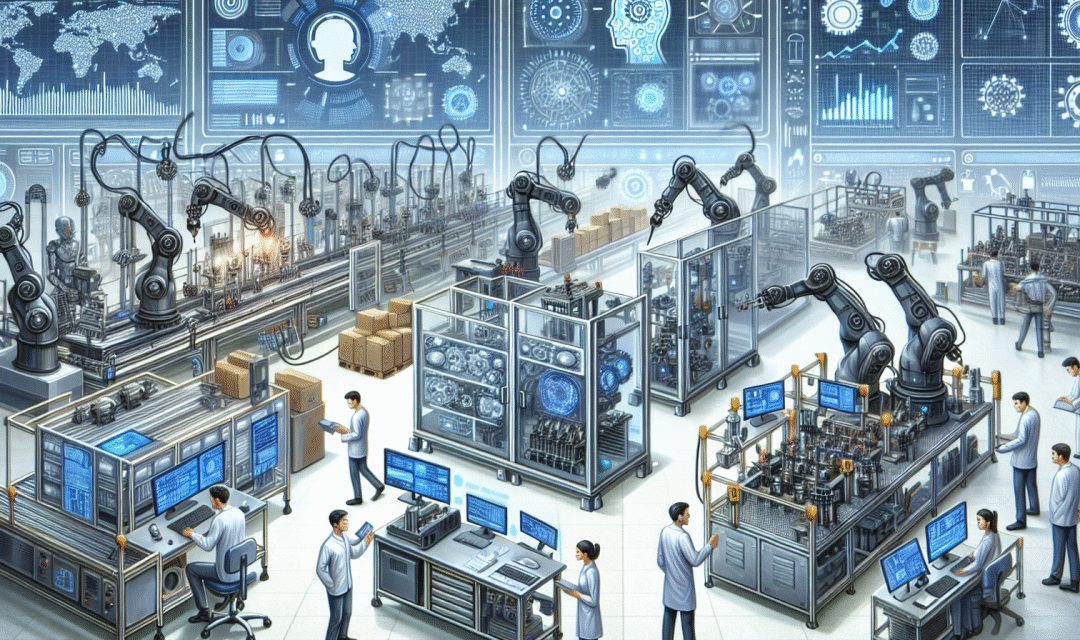

Technologies for Detecting Missing Parts

Various technologies are employed in the detection of missing parts in manufacturing processes. Some of the most effective methods include:

Vision Inspection Systems

These systems use cameras and image processing software to scan products and identify missing components. They are highly efficient and can be integrated into production lines for real-time monitoring. For more insights, visit PCE Instruments.

Stroboscopic Systems

Stroboscopic lights flash at high speeds to create the illusion of slow-motion, allowing for detailed inspection of fast-moving parts. Learn more about the workings of stroboscopic systems at Raptor Supplies.

Automated Counting Systems

These systems use sensors to count parts as they pass through specific checkpoints, ensuring that the correct number of components is present in each assembly.

Weight-Based Systems

By weighing products at different stages of assembly, these systems can detect discrepancies that indicate missing parts.

Integrating Detection Systems into Manufacturing Processes

For optimal results, detection systems should be seamlessly integrated into existing manufacturing processes. This involves careful planning and consideration of factors such as:

Process Flow

Understanding the flow of materials and products is essential for determining where and how detection systems should be implemented.

System Compatibility

Ensuring that new detection systems are compatible with existing equipment and software is crucial for seamless integration.

Benefits of Advanced Detection Systems

Implementing advanced detection systems offers numerous benefits, including:

Improved Quality Control

By accurately identifying missing parts, these systems enhance quality control and reduce the risk of defective products reaching customers.

Increased Efficiency

Automated detection systems streamline the inspection process, reducing the need for manual checks and allowing for faster production times.

Cost Savings

By preventing defective products from reaching the market, businesses can avoid costly recalls and potential legal issues.

Challenges in Implementing Detection Systems

While the benefits are clear, implementing detection systems in manufacturing processes can present challenges, such as:

Initial Investment

The cost of purchasing and installing advanced detection systems can be significant, particularly for small businesses.

Training Requirements

Employees may require training to effectively operate and maintain new detection systems, adding to the overall implementation cost.

System Maintenance

Regular maintenance is necessary to ensure the continued accuracy and reliability of detection systems, which can be resource-intensive.

Case Studies: Successful Implementation of Detection Systems

Several companies have successfully implemented detection systems to improve quality control and product reliability. For example, a leading automotive manufacturer integrated vision inspection systems into their production lines, resulting in a 25% reduction in defective products. Similarly, a consumer electronics company employed stroboscopic systems to inspect components at high speeds, significantly enhancing their production efficiency. For further reading, consider exploring the benefits of stroboscopic systems in energy-efficient systems.

Future Trends in Missing Parts Detection

The future of missing parts detection looks promising, with advancements in technology paving the way for even more efficient and accurate systems. Some emerging trends include:

Artificial Intelligence and Machine Learning

AI and machine learning algorithms can analyze vast amounts of data to identify patterns and anomalies, improving the accuracy of detection systems.

IoT Integration

The Internet of Things (IoT) allows for real-time data collection and analysis, enabling more responsive and adaptive detection systems.

Augmented Reality

AR technology can provide real-time visual feedback to operators, enhancing their ability to identify missing parts during manual inspections.

Conclusion

The detection of missing parts is a critical aspect of quality control in manufacturing. By understanding the causes of missing components and implementing advanced detection systems, businesses can significantly enhance their product quality, efficiency, and customer satisfaction. As technology continues to evolve, the adoption of innovative solutions will be key to staying competitive in the ever-changing manufacturing landscape.

FAQ

What are the benefits of using vision inspection systems?

Vision inspection systems provide real-time monitoring and accurate detection of missing parts, improving product quality and reducing the risk of recalls.

How can stroboscopic systems enhance detection processes?

Stroboscopic systems allow for detailed inspection of fast-moving parts by creating the illusion of slow-motion, ensuring that no components are missed.

What challenges might businesses face when implementing detection systems?

Challenges include the initial investment cost, training requirements for employees, and ongoing system maintenance to ensure accuracy and reliability.

This article contains affiliate links. We may earn a commission at no extra cost to you.