The question of whether frequency impacts inspection speed is crucial for professionals in various industries, especially for those involved in quality assurance and equipment maintenance. Understanding the dynamics between inspection frequency and speed can greatly enhance operational efficiency and ensure high standards of quality and safety. This article delves into the intricacies of this relationship, providing insights that are both informative and practical for industry QA professionals.

Understanding the Basics: What is Inspection Frequency?

Before diving into the effects of frequency on inspection speed, it’s essential to define what inspection frequency entails. Put simply, inspection frequency refers to how often inspections are conducted within a given timeframe. This can vary significantly depending on the industry, the type of equipment or process being inspected, and the specific regulatory requirements. For more detailed insights on this, you can visit this resource.

The Importance of Frequency in Inspection

Why is frequency such a critical factor in inspection processes? Regular and consistent inspections help identify potential issues before they escalate into major problems. This not only saves time and resources but also ensures compliance with safety standards. Moreover, frequent inspections can lead to better data collection, which ultimately improves decision-making processes.

Frequency vs. Speed: Finding the Balance

One of the key challenges in inspection management is finding the optimal balance between frequency and speed. Increasing the frequency of inspections can potentially slow down the process, especially if it involves extensive data collection and analysis. On the other hand, reducing the frequency might speed up the process but could lead to oversight of critical issues. Therefore, it’s imperative to strike a balance that ensures thoroughness without compromising efficiency.

Factors Influencing Inspection Speed

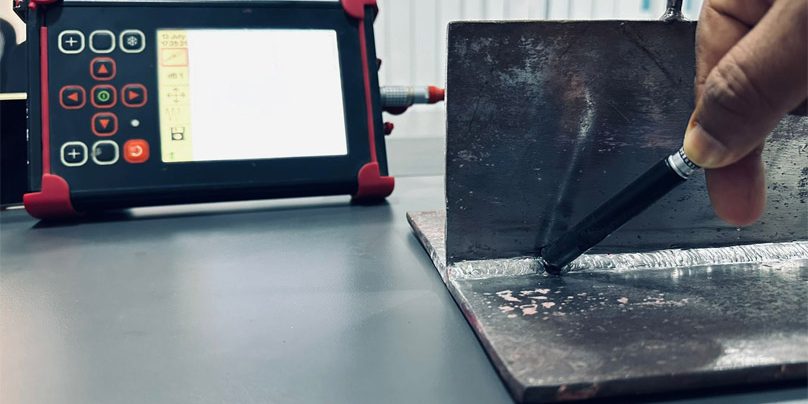

Several factors can influence the speed of inspections, including the complexity of the equipment, the skills and experience of the inspectors, and the tools and technologies used during the inspection process. Advancements in technology, such as automation and digital inspection tools, have significantly enhanced inspection speed while maintaining accuracy and precision. For more on innovative technologies, check out Innovations in Synchronization Technologies.

Technological Advancements Impacting Inspection Frequency

The integration of cutting-edge technologies has revolutionized inspection processes, allowing for more frequent and faster inspections. Technologies such as drones, AI-powered analysis tools, and IoT devices provide real-time data and insights, enabling inspectors to conduct assessments more efficiently. These advancements reduce the time required for inspections and allow for more frequent checks without sacrificing speed. To learn more about the role of technology in inspections, visit Frequency in Inspection Tools.

Case Studies: Real-World Applications

Case Study 1: Frequency Analysis in Wind Turbine Inspection

In the renewable energy sector, particularly in wind turbine maintenance, optimizing inspection frequency is vital. Regular inspections are necessary to ensure the turbines operate efficiently and safely. By leveraging advanced technologies, companies can conduct more frequent inspections without significantly increasing the time required for each inspection. This approach not only improves operational efficiency but also enhances the lifespan of the turbines. For a detailed analysis, refer to Frequency Analysis in Wind Turbine Inspection.

Case Study 2: Quantum Synchronization in Inspection Tools

Another notable example is the application of quantum synchronization in inspection tools. This technology allows for precise timing and coordination in inspections, significantly improving both frequency and speed. The integration of quantum technologies has been a game-changer, providing unmatched accuracy and efficiency in inspections across various industries. More insights can be found in Quantum Synchronization in Inspection Tools.

Optimizing Inspection Process: A Strategic Approach

Optimizing the inspection process involves strategic planning and the effective use of resources. By assessing the specific needs of the industry and the equipment, companies can determine the appropriate frequency of inspections. This involves considering factors such as the criticality of the equipment, historical data on failures, and the potential impact of downtime. Implementing a data-driven approach ensures that inspections are conducted at the right intervals, maximizing both speed and efficiency.

Training and Skill Development

The role of skilled inspectors cannot be understated in ensuring efficient inspection processes. Regular training and skill development programs are crucial for equipping inspectors with the latest techniques and technologies. This not only enhances their capability to conduct inspections swiftly but also ensures that they can accurately identify and address potential issues during inspections.

Future Trends in Inspection Frequency and Speed

The future of inspections lies in the continuous evolution of technologies and methodologies. As industries move towards more digital and automated processes, the frequency and speed of inspections are expected to increase. This trend will be driven by advancements in AI, machine learning, and real-time data analytics, allowing for more proactive and predictive maintenance strategies.

Conclusion: The Impact of Frequency on Inspection Speed

In conclusion, the relationship between inspection frequency and speed is complex yet critical for ensuring operational efficiency and safety. By understanding and optimizing this relationship, industries can achieve significant improvements in their inspection processes, leading to enhanced productivity and reduced downtime. As technology continues to advance, the potential for faster and more frequent inspections will continue to grow, offering exciting opportunities for industry professionals.

FAQ

How does inspection frequency impact operational costs?

Increasing the frequency of inspections can potentially raise operational costs due to the need for more resources and time. However, it can also prevent costly repairs and downtime by identifying issues early.

What role does technology play in enhancing inspection speed?

Technology plays a pivotal role in enhancing inspection speed by providing tools that streamline the process, reduce manual labor, and offer real-time data analysis, making inspections faster and more efficient.

Can frequent inspections improve equipment lifespan?

Yes, frequent inspections can improve equipment lifespan by ensuring that any potential issues are identified and addressed promptly, preventing wear and tear and extending the overall life of the equipment.

This article contains affiliate links. We may earn a commission at no extra cost to you.