In the realm of industrial quality assurance, frequency mismatch issues in ultrasonic inspection have emerged as a significant challenge. These issues can lead to inaccurate readings and potential safety hazards if not properly addressed. Understanding the root causes and implications of these frequency mismatches is crucial for industry professionals aiming to maintain high standards of inspection and safety.

What is Ultrasonic Inspection?

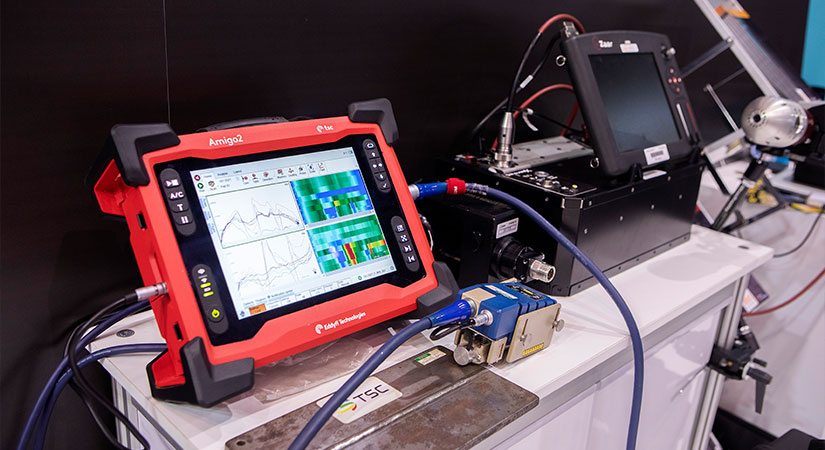

Ultrasonic inspection is a non-destructive testing (NDT) method that uses high-frequency sound waves to detect flaws in materials. This technique is widely used in various industries, including aerospace, automotive, and construction. By sending ultrasonic waves through a material and analyzing the reflected signals, inspectors can identify cracks, voids, and other defects that are not visible to the naked eye.

How Frequency Plays a Role

The effectiveness of ultrasonic inspection largely depends on the frequency of the sound waves used. Different materials and defect types require specific frequencies to obtain accurate results. This is where frequency mismatch issues come into play. A mismatch occurs when the frequency of the ultrasonic waves does not align with the optimal frequency needed for a particular inspection task.

Causes of Frequency Mismatch

Equipment Calibration Errors

One of the most common causes of frequency mismatch is improper calibration of inspection equipment. Regular calibration ensures that the equipment emits ultrasonic waves at the correct frequency. Without proper calibration, the risk of frequency mismatch increases, leading to unreliable inspection results.

Material Variability

Different materials respond differently to ultrasonic waves. Variations in material composition, density, and thickness can affect the optimal frequency needed for inspection. When the inspection frequency does not match these material properties, it can result in inaccurate readings.

Environmental Factors

Temperature, humidity, and other environmental conditions can also impact the frequency of ultrasonic waves. These factors can cause changes in wave propagation, leading to frequency mismatches during inspection.

Consequences of Frequency Mismatch

When frequency mismatches occur, the consequences can be severe. Inaccurate inspection results can lead to undetected defects, compromising the safety and integrity of materials and structures. In industries where safety is paramount, such as aerospace and nuclear energy, the implications of undetected defects can be catastrophic.

Impact on Safety

Undetected defects due to frequency mismatch pose significant safety risks. In critical applications, such as aircraft components or pressure vessels, these defects can lead to catastrophic failures, endangering lives and property.

Financial Implications

Beyond safety concerns, frequency mismatch issues can also have financial repercussions. Inaccurate inspections may necessitate costly re-inspections, repairs, or replacements. Additionally, companies may face legal liabilities and reputational damage if defects are discovered after products have been deployed.

Addressing Frequency Mismatch Issues

Regular Equipment Calibration

To mitigate frequency mismatch issues, it is essential to perform regular calibration of inspection equipment. Calibration ensures that the equipment operates at the correct frequency, reducing the risk of mismatches and improving inspection accuracy.

Material-Specific Calibration

In addition to regular calibration, material-specific calibration can be beneficial. By tailoring the calibration process to the specific materials being inspected, professionals can ensure that the ultrasonic frequency is optimized for accurate readings.

Environmental Controls

Implementing environmental controls can also help address frequency mismatch issues. By maintaining stable temperature and humidity levels during inspections, companies can minimize the impact of environmental factors on ultrasonic wave propagation.

Innovations in Ultrasonic Inspection

Recent advancements in ultrasonic inspection technology have introduced new solutions for addressing frequency mismatch issues. These innovations include advanced signal processing techniques and adaptive frequency adjustment capabilities.

Adaptive Frequency Adjustment

New ultrasonic inspection devices are equipped with adaptive frequency adjustment features. These devices can dynamically alter the frequency of ultrasonic waves based on real-time data, ensuring optimal inspection results regardless of material or environmental conditions.

Advanced Signal Processing

Advanced signal processing algorithms enhance the accuracy of ultrasonic inspections by filtering out noise and compensating for frequency mismatches. These algorithms enable inspectors to obtain clearer, more reliable data from their inspections.

Future Trends in Ultrasonic Inspection

As technology continues to evolve, the future of ultrasonic inspection looks promising. Emerging trends focus on improving inspection accuracy and efficiency while reducing the impact of frequency mismatch issues.

Integration with AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning into ultrasonic inspection processes is expected to revolutionize the field. These technologies can analyze large datasets to identify patterns and optimize inspection parameters, reducing the likelihood of frequency mismatches.

Enhanced Data Analytics

Enhanced data analytics capabilities are enabling inspectors to extract more insights from ultrasonic inspection data. By analyzing trends and patterns, companies can make informed decisions to improve inspection processes and outcomes.

Conclusion

In conclusion, frequency mismatch issues in ultrasonic inspection present significant challenges for industry professionals. By understanding the causes and consequences of these issues, companies can implement strategies to mitigate their impact and improve inspection accuracy. Regular equipment calibration, material-specific adjustments, and technological innovations are key to overcoming frequency mismatch challenges and ensuring the safety and integrity of materials and structures.

FAQs

What is frequency mismatch in ultrasonic inspection?

Frequency mismatch occurs when the frequency of ultrasonic waves used in inspection does not align with the optimal frequency needed for accurate results, leading to potential inaccuracies in detecting defects.

How can frequency mismatch issues be prevented?

Preventing frequency mismatch issues involves regular equipment calibration, material-specific adjustments, and implementing environmental controls to minimize the impact of external factors.

What are the consequences of frequency mismatch?

Consequences of frequency mismatch include inaccurate inspection results, undetected defects, safety risks, financial implications, and potential legal liabilities for companies.

For more information on inspection frequency and schedules, visit The Checker Blog.

This article contains affiliate links. We may earn a commission at no extra cost to you.