High-Speed Microbial Fermentation Monitoring

Challenges in Microbial Fermentation

01

High-Speed Production

Microbial fermentation processes require constant monitoring to optimize production yields.

02

Defect Detection

Identifying contamination, fermentation inefficiencies, and deviations from optimal conditions.

03

Consistency and Quality

Ensuring consistent microbial growth and fermentation quality.

04

Efficiency Requirements

Reducing manual observation and improving monitoring efficiency.

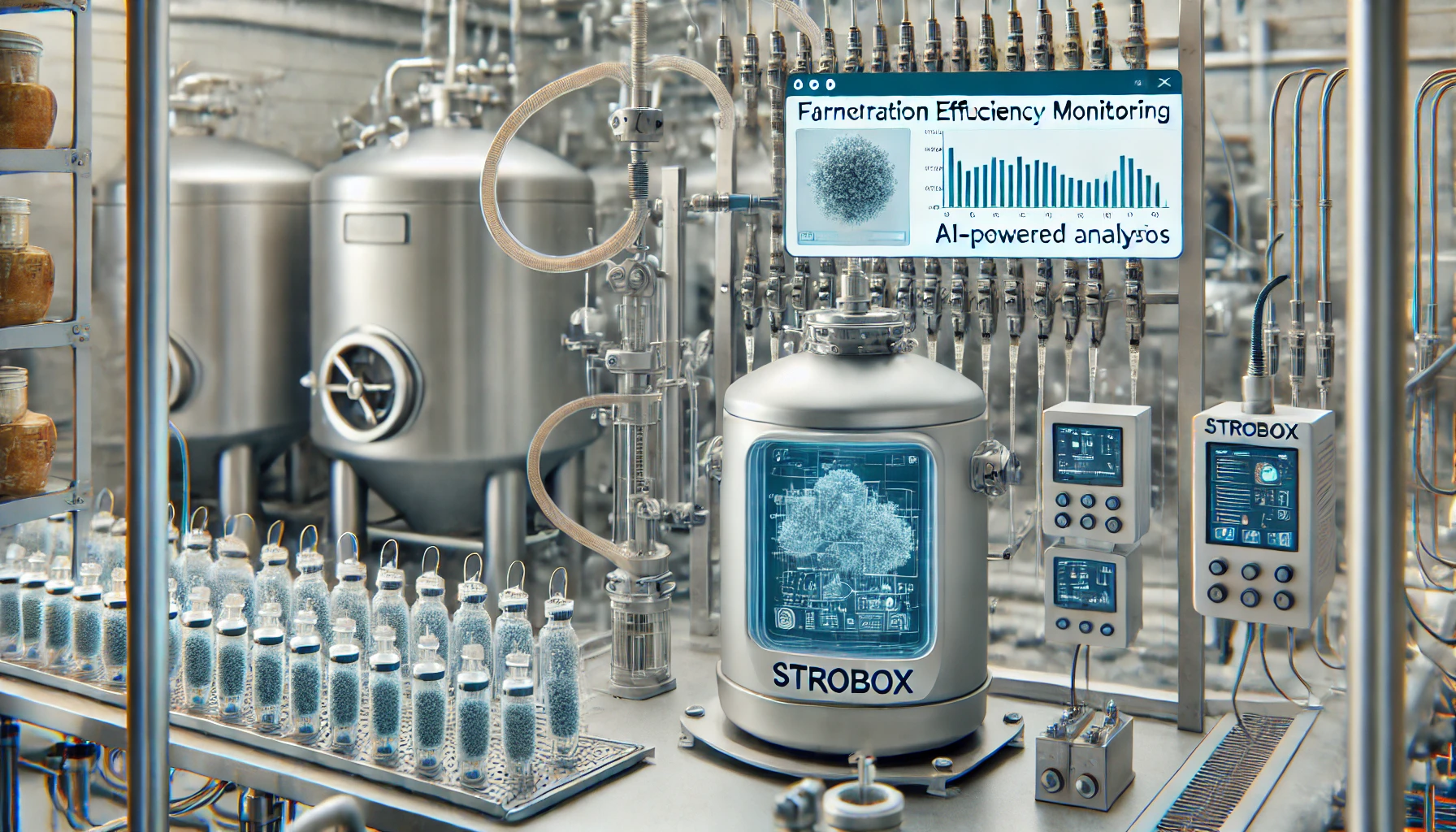

StroboX Solution

StroboX leverages AI and stroboscopic technology to automate the monitoring of microbial fermentation processes. It can capture multiple stroboscopic events to detect various issues simultaneously.

Key Features and Integration Potential

- High-Resolution Imaging: Captures detailed images of microbial cultures and fermentation processes.

- AI-Powered Analysis: Uses AI to analyze fermentation conditions, identify contamination, and detect inefficiencies.

- Real-Time Monitoring: Provides continuous monitoring and instant alerts for any detected issues.

- Integration with Bioprocess Systems: Integrates with existing bioprocess control systems for streamlined workflows.

Usecases

Contamination Detection

Feature: High-Resolution Imaging

Benefit: Detects bacterial or fungal contamination in real-time, ensuring the purity of fermentation processes.

Fermentation Efficiency Monitoring

Feature: AI-Powered Analysis

Benefit: Monitors fermentation efficiency, identifying deviations from optimal conditions and enabling timely intervention.

Potential Benefits

01

Increased Efficiency

Reduces the need for manual monitoring, freeing up bioprocess engineers for other tasks.

02

Enhanced Accuracy

Provides precise and consistent monitoring, ensuring high-quality fermentation processes.

03

Cost Savings

Minimizes the risk of contaminated or inefficient fermentations, reducing the need for costly rework.

04

Improved Quality

Ensures reliable and high-yield microbial production processes.

Challenges and Considerations

- Technical Complexity: Ensuring the system can handle various microbial strains and fermentation conditions.

- Quality Assurance: Maintaining high standards in automated defect detection.

- Integration Challenges: Integrating seamlessly with existing bioprocess systems.