01

High-Speed Rotation

HVAC systems contain rotating equipment like fans and blowers that operate at high speeds.

02

Defect Detection

Identifying defects such as imbalance, misalignment, and surface damage.

03

Consistency and Quality

Ensuring each component meets strict quality and performance standards.

04

Efficiency Requirements

Reducing downtime and maintaining high production speeds.

StroboX Solution

Key Features and Integration Potential

- Automated Speed Detection: Measures rotation speed and adjusts the strobe effect.

- High-Resolution Imaging: Captures detailed images of rotating components in motion.

- AI-Powered Analysis: Compares images to standard quality benchmarks to identify defects.

- Instant Alerts: Provides immediate notifications for detected defects.

- Integration with Manufacturing Systems: Integrates with existing production control systems for streamlined workflow.

Usecases

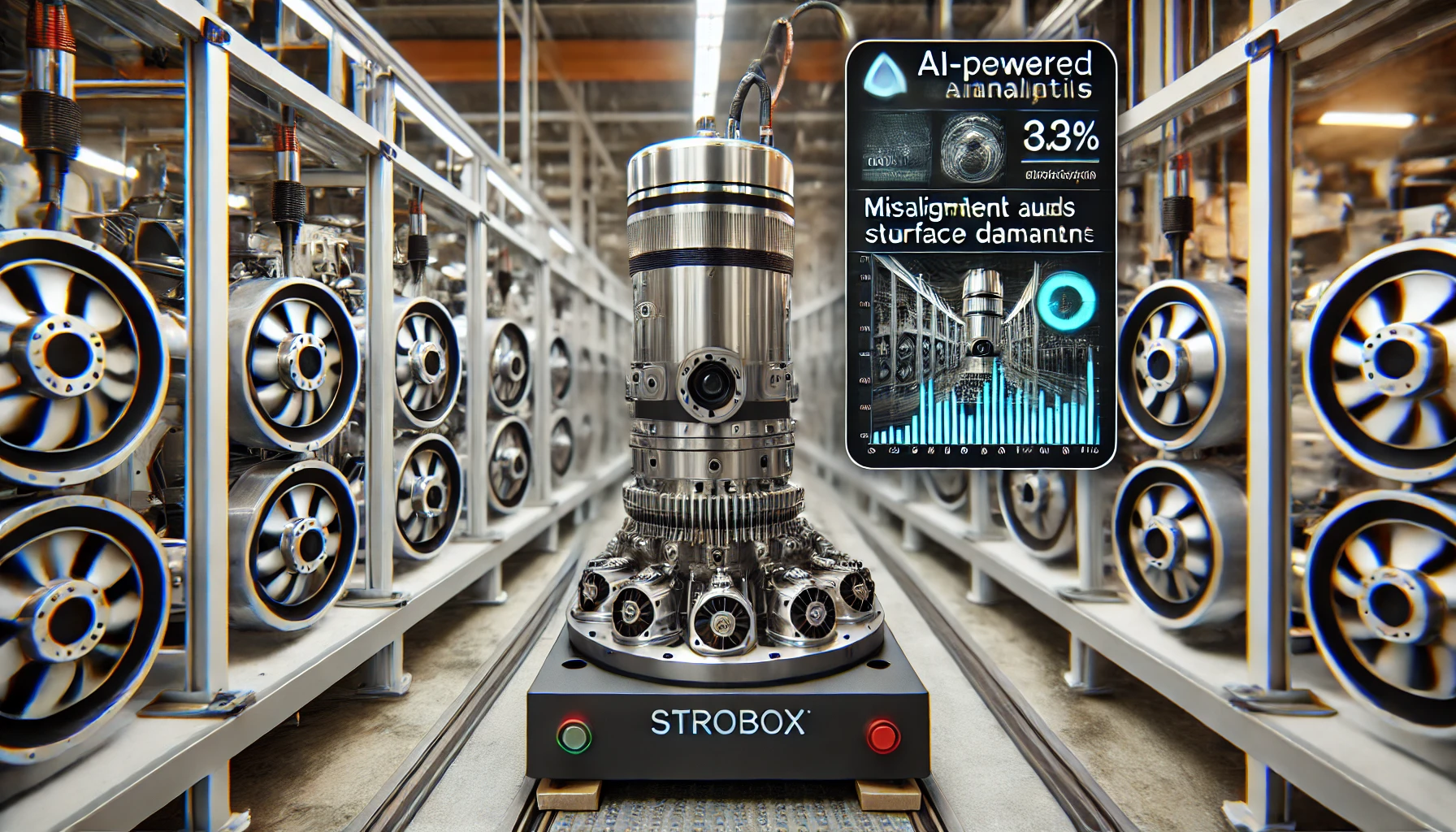

Feature: High-Resolution Imaging

Benefit: Detects imbalance in real-time, ensuring smooth operation and reducing wear and tear.

Feature: AI-Powered Analysis

Benefit: Identifies misalignment and surface damage, enhancing the reliability and performance of HVAC components.

Potential Benefits

01

Increased Efficiency

Automates the inspection process, significantly reducing time and labor costs.

02

Enhanced Accuracy

Provides precise and consistent quality checks, minimizing the risk of defective products.

03

Cost Savings

Reduces the need for extensive manual inspections and rework.

04

Improved Quality

Ensures high standards of quality across all HVAC components, enhancing product reliability and performance.

Challenges and Considerations

- Technical Complexity: Ensuring the system can handle various rotating equipment designs and materials.

- Quality Assurance: Maintaining high standards in automated defect detection.

- Integration Challenges: Integrating with existing manufacturing systems and workflows.