Understanding the modern marvel of digital tachometers is crucial for industry professionals and enthusiasts alike. Digital tachometers have revolutionized the way we measure the speed of rotating objects, providing accurate and reliable data.

But how does a digital tachometer work? This article aims to delve into this question, offering an engaging and in-depth analysis.

What is a Digital Tachometer?

A digital tachometer is an instrument used to measure the rotational speed of a shaft or disk, typically in revolutions per minute (RPM). Unlike analog tachometers, digital tachometers provide a digital display of the measured speed, often with greater precision and data logging capabilities.

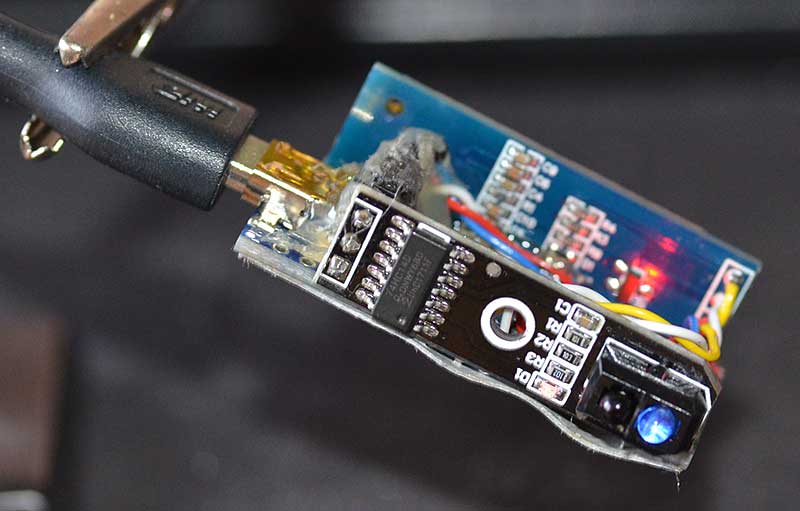

The Core Components of a Digital Tachometer

1. Sensor

The sensor is a vital component that detects the rotation. There are various types of sensors used in digital tachometers, such as optical, magnetic, and capacitive sensors.

2. Signal Processor

This component processes the raw data collected by the sensor. The signal processor converts signals into a form that can be displayed and analyzed.

3. Display

The display shows the RPM or other measurements. Most digital tachometers feature LED or LCD displays for clarity.

How Does the Sensor Work?

Optical Sensors

Optical sensors use a beam of light to detect rotation. When the light beam is interrupted periodically by the rotating object, the tachometer calculates the speed based on the frequency of interruptions.

Magnetic Sensors

Magnetic sensors detect the rotational speed by generating a voltage when a metallic object passes through a magnetic field.

The Signal Processing Mechanism

Once the sensor gathers the rotational data, it is transmitted to the signal processor. This processor converts the analog signals into digital signals, a process involving several steps including filtering, amplification, and analog-to-digital conversion.

Filtering

Filtering is crucial because it removes any noise that may affect the signal, ensuring that only useful data is processed.

Amplification

The signal may need to be amplified to a level suitable for further processing.

Analog-to-Digital Conversion

The final step in signal processing is converting the analog signal into a digital format, which can be displayed on the tachometer’s screen.

Display Mechanism

The processed signal is then sent to the display component, which shows the rotational speed. Most digital tachometers use either LCD or LED displays. These displays offer high visibility and are easy to read.

Advantages of Digital Tachometers

Digital tachometers come with several advantages over their analog counterparts:

1. Accuracy

Digital tachometers provide precise measurements, which are crucial for many industrial applications.

2. Data Logging

Many digital tachometers have data logging features, allowing users to record and analyze speed data over time.

3. Durability

These instruments are often more durable and reliable, making them suitable for harsh industrial environments.

Applications of Digital Tachometers

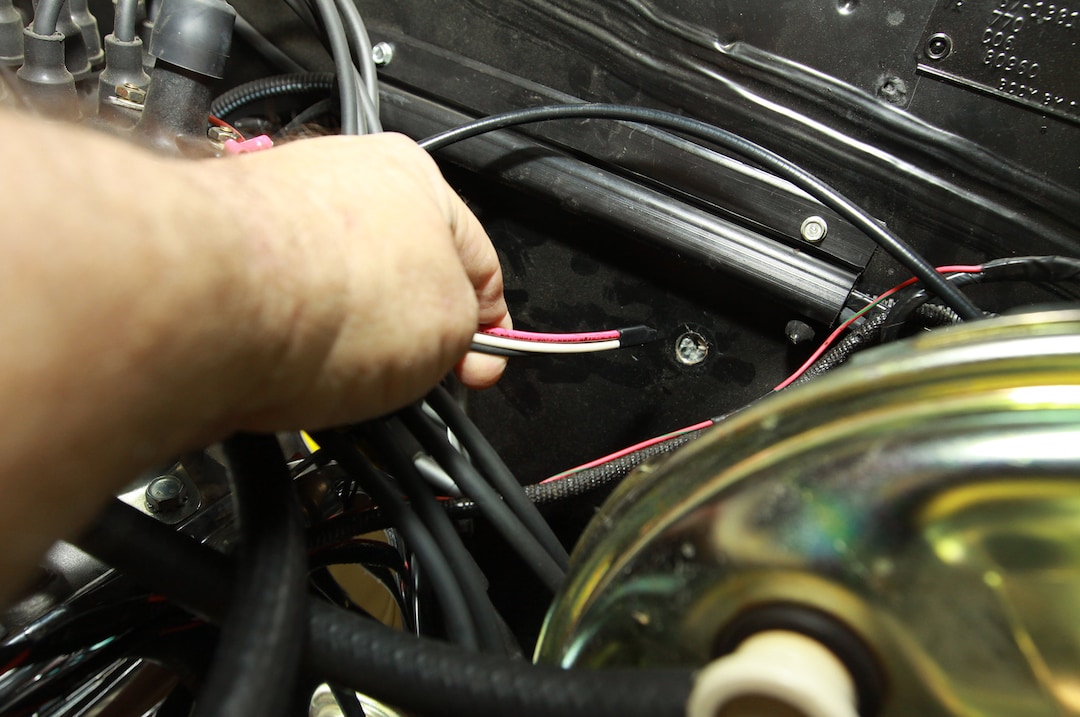

1. Automotive Industry

Digital tachometers are widely used in the automotive industry to measure the RPM of engines, helping in performance tuning and diagnostics.

2. Manufacturing

In manufacturing settings, digital tachometers are used to monitor the speed of various machinery to ensure optimal performance and safety. Check out this high speed inspection for an example.

3. Research and Development

In research labs, digital tachometers provide accurate measurements needed for experiments and prototype testing.

Conclusion

Understanding how a digital tachometer works is essential for industry professionals and technology enthusiasts. With their precise measurements and advanced features, digital tachometers have become indispensable tools in various sectors, from automotive to manufacturing and beyond.

For more detailed information on tachometers, you may visit this Britannica article.

Frequently Asked Questions

1. What types of sensors are used in digital tachometers?

There are several types of sensors used in digital tachometers, including optical, magnetic, and capacitive sensors. Each type offers different advantages, depending on the application.

2. How accurate are digital tachometers?

Digital tachometers are highly accurate, often providing measurements with very low margins of error. This accuracy makes them ideal for industrial and scientific applications.

3. Can digital tachometers be used in harsh environments?

Yes, many digital tachometers are designed to be durable and reliable even in harsh industrial environments. They are often built with materials that can withstand high temperatures, dust, and vibrations.