Have you ever wondered how engineers accurately measure the rotational speed of machinery? The answer lies in the mechanical tachometer. This remarkable instrument plays a significant role in various industries, ensuring machinery operates at optimal speeds. In this article, we will delve deep into the workings of a mechanical tachometer, giving you a comprehensive understanding of its incredible technology.

The mechanical tachometer has been a cornerstone in industries due to its reliability and precision. In the initial paragraphs, we will unveil its fundamental principles. From its inception to its present-day applications, this instrument’s journey is. We’re about to explore this tremendous technology approved by experts. We will break down its components, explain its working principles, and discuss its numerous applications in various fields.

1. What is a Mechanical Tachometer?

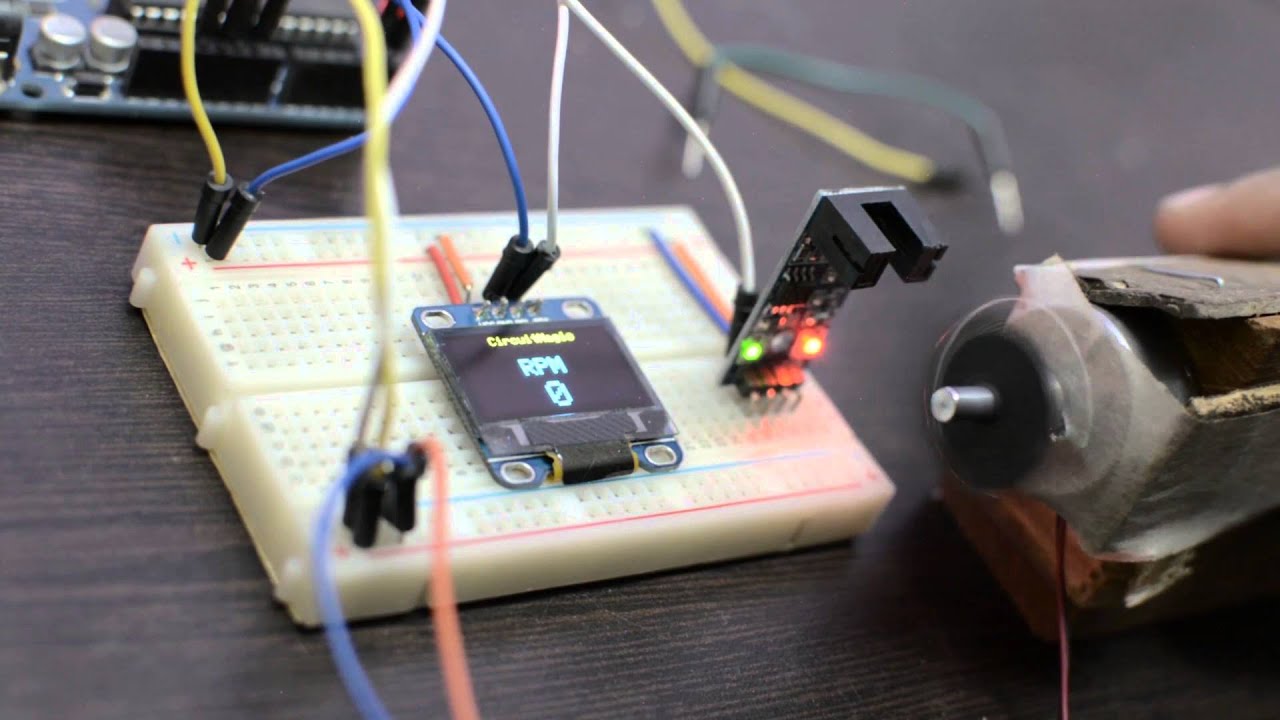

A mechanical tachometer is a device used to measure the rotational speed of an object, typically in revolutions per minute (RPM). This instrument is crucial in applications where assessing the speed of rotating machinery is essential for performance and safety.

2. Historical Context

The invention of mechanical tachometers dates back to the early 19th century. Initially, these devices were rudimentary and primarily used in steam engines. Over time, technological advancements led to the development of more sophisticated and accurate models.

3. Basic Components of a Mechanical Tachometer

a. Dial Indicator

The dial indicator displays the speed reading. It’s designed to provide clear and precise measurements.

b. Drive Mechanism

The drive mechanism is the component that interacts directly with the rotating machinery to measure its speed.

c. Governor Mechanism

The governor mechanism helps maintain the stability of the readings by regulating the effect of speed on the dial indicator.

4. Working Principle of a Mechanical Tachometer

Mechanical tachometers operate based on the principle of centrifugal force. As the rotating object turns, it causes the drive mechanism to spin. This motion is transferred to the governor mechanism, causing it to move. The centrifugal force generated by this motion translates into a readable speed on the dial indicator.

5. Types of Mechanical Tachometers

a. Hand-Held Tachometers

These are portable devices used for spot checks in the field.

b. Panel-Mounted Tachometers

Installed on control panels, these tachometers provide continuous monitoring.

6. Applications in Various Industries

a. Automotive Industry

Mechanical tachometers are used to measure the RPMs of engines to ensure optimal performance.

b. Manufacturing Sector

They monitor the speed of machinery, ensuring production processes run smoothly.

c. Aerospace

In aircraft, tachometers are crucial for monitoring the speed of engines and other rotating components.

7. Advantages of Mechanical Tachometers

a. Durability

These instruments are known for their robust construction and long lifespan.

b. Precision

Mechanical tachometers provide highly accurate readings, making them indispensable in various applications.

8. Limitations of Mechanical Tachometers

Despite their advantages, mechanical tachometers have limitations, such as being prone to wear and tear and requiring regular calibration.

9. How to Calibrate a Mechanical Tachometer

Proper calibration is essential to ensure accurate readings. This section will guide you step-by-step on how to calibrate your tachometer.

10. Maintenance Tips to Prolong Lifespan

Follow these maintenance tips to keep your tachometer in top condition:

a. Regular Cleaning

Keep the device clean to avoid dust and debris from affecting its performance.

b. Lubrication

Lubricate the moving parts to ensure smooth operation.

11. Safety Precautions When Using a Mechanical Tachometer

Always follow these safety precautions:

a. Proper Handling

Handle the device carefully to avoid damage.

b. Protective Gear

Wear protective gear when using the tachometer in hazardous environments.

12. Recent Technological Advancements

The evolution of mechanical tachometers continues with recent advancements enhancing their accuracy and ease of use.

13. Future Trends in Mechanical Tachometers

Experts foresee a future where mechanical tachometers will integrate with digital technologies for even greater precision and functionality.

14. Comparing Mechanical and Digital Tachometers

Here, we’ll compare mechanical and digital tachometers to help you decide which one suits your needs best.

a. Accuracy

While mechanical tachometers are highly accurate, digital tachometers offer even greater precision.

b. Durability

Mechanical tachometers are generally more durable due to their robust construction.

15. Conclusion: The Relevance of Mechanical Tachometers Today

In an age dominated by digital technology, mechanical tachometers remain relevant due to their ruggedness, reliability, and precision. They continue to play a critical role in various industries, from automotive to aerospace.

For more detailed information about how tachometers work, visit this link.