A milling machine is a powerful tool used extensively in the manufacturing industry. But how does a milling machine work? This article, approved by experts, will delve deep into the mechanics, variety, and applications of milling machines. Our primary aim is to provide a thorough understanding of the subject matter for our readers.

1. Introduction to Milling Machines

Milling machines are indispensable tools in manufacturing, capable of performing complex operations with incredible precision. Let’s understand their significance in the industry.

2. Historical Evolution of Milling Machines

Milling machines have a rich history dating back to the industrial revolution. This section outlines their evolution from simple, manually operated devices to sophisticated CNC milling machines.

a. Early Milling Machines

The earliest milling machines were simple and manually operated. These machines laid the groundwork for subsequent advancements.

b. The Advent of CNC Technology

The introduction of Computer Numerical Control (CNC) revolutionized milling machines, making them more efficient and versatile. Learn more about CNC technology here.

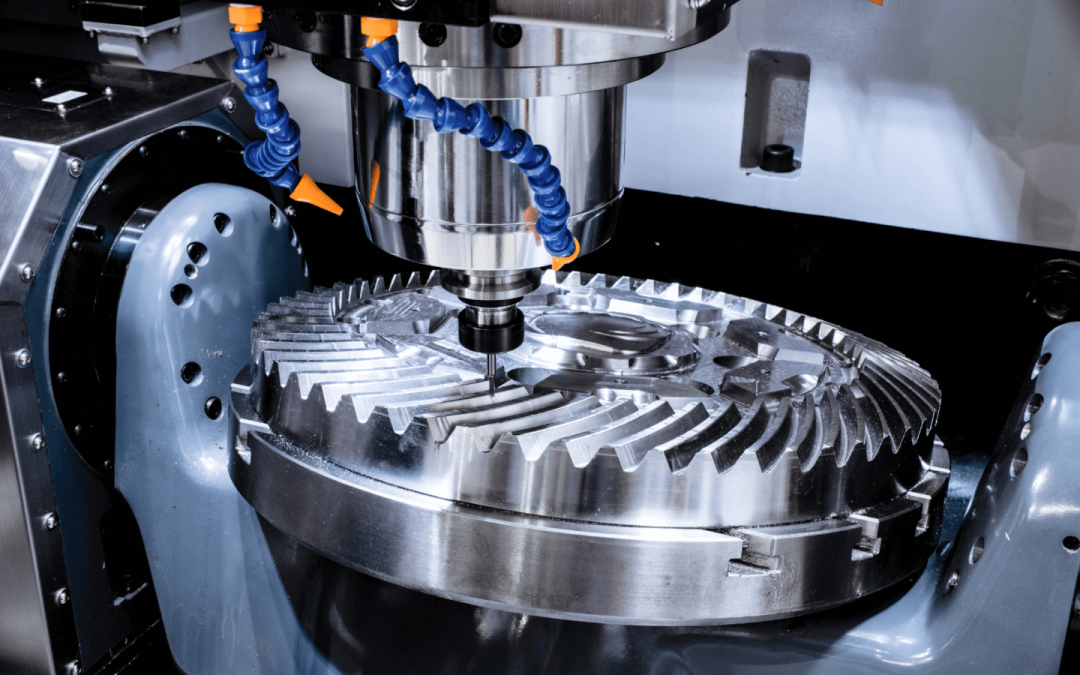

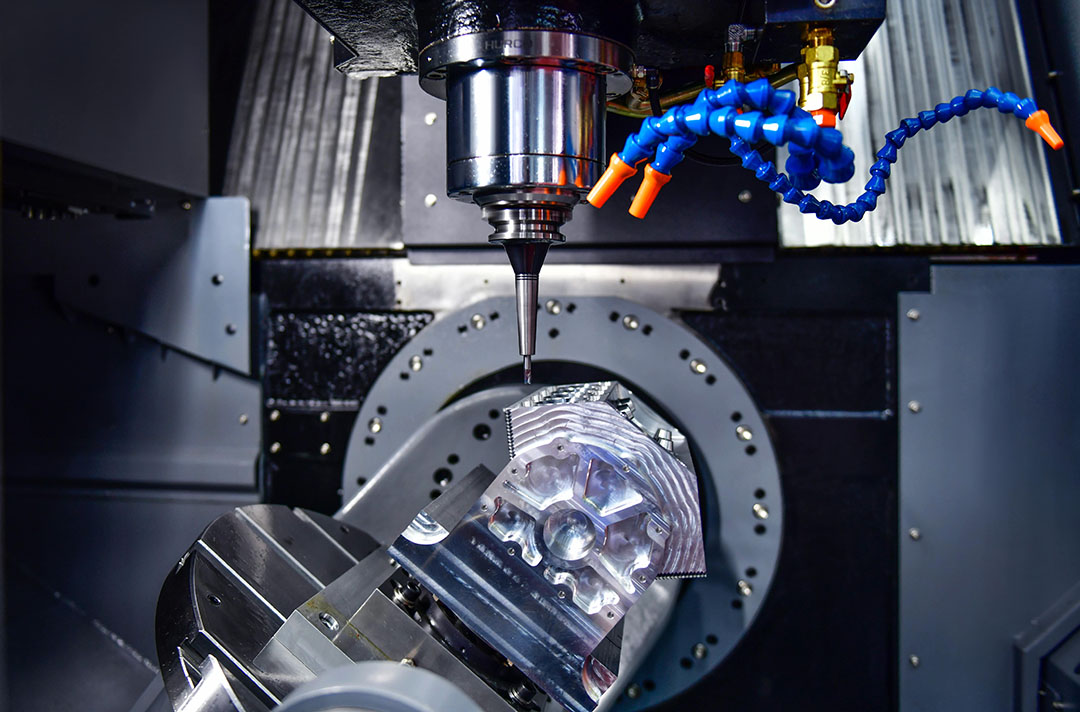

3. Key Components of a Milling Machine

Understanding the primary components of a milling machine is crucial. These components work in harmony to produce high-quality parts.

a. The Spindle

The spindle is the heart of the milling machine, responsible for rotating the cutting tool.

b. The Worktable

The worktable holds the material being machined and moves it in different directions as needed.

c. The Control Panel

The control panel allows the operator to set the desired cutting parameters and control the machine’s movements.

4. The Milling Process

Now that we know the components, let’s delve into the milling process itself. How does it all work together to shape materials?

a. Workpiece Setup

The first step involves securing the workpiece on the worktable. Precision is vital to ensure the accuracy of the final product.

b. Tool Selection

Choosing the right cutting tool for the job is crucial. Different tools are designed for specific materials and cutting operations.

c. Cutting Operations

The actual cutting involves moving the tool and the workpiece in precise motions. Learn more about the technical aspects of cutting operations here.

5. Types of Milling Machines

There are several types of milling machines, each with its unique features and applications. Let’s explore some of the most common ones.

a. Vertical Milling Machines

Vertical milling machines have a vertically oriented spindle and are used for various cutting operations.

b. Horizontal Milling Machines

Horizontal milling machines have a horizontally oriented spindle, making them suitable for heavy-duty cutting jobs.

c. CNC Milling Machines

CNC milling machines are the most advanced, capable of performing complex operations with minimal human intervention. Learn about this type of milling.

6. Applications of Milling Machines

Milling machines are used across various industries for numerous applications. Let’s look at some common uses.

a. Automotive Industry

In the automotive industry, milling machines are vital for producing engine parts, transmission components, and more.

b. Aerospace Industry

The aerospace industry relies heavily on milling machines for manufacturing precise and critical components. Explore other uses in the field.

c. Medical Device Manufacturing

Precision is paramount in medical device manufacturing, and milling machines play a significant role in producing these devices.

7. Advantages of Milling Machines

Milling machines offer numerous advantages that make them invaluable in manufacturing. Here are a few key benefits.

a. Precision and Accuracy

Milling machines provide unparalleled precision and accuracy, ensuring high-quality output.

b. Versatility

They are incredibly versatile, capable of performing a wide range of cutting operations on various materials.

c. Efficiency

Milling machines improve efficiency, reducing the time required to produce complex parts.

8. Common Materials Used in Milling

Different materials can be machined using milling machines. Here are some commonly used materials.

a. Metals

Metals like aluminum, steel, and titanium are frequently machined using milling techniques.

b. Plastics

Plastics are also commonly machined, especially in industries such as automotive and medical.

c. Composites

Composite materials, known for their strength and lightweight properties, are increasingly used in milling operations.

9. Maintenance and Care of Milling Machines

Proper maintenance is crucial to ensure the longevity and performance of milling machines. Here are some tips for upkeep.

a. Regular Inspections

Conduct regular inspections to identify and address any potential issues before they become major problems.

b. Lubrication

Proper lubrication of moving parts is essential to minimize wear and tear.

c. Cleaning

Keep the machine clean and free from debris to prevent damage and ensure smooth operation.

10. Safety Precautions When Using Milling Machines

Safety should always be a top priority when operating milling machines. Here are some important safety tips.

a. Personal Protective Equipment (PPE)

Always wear appropriate PPE, such as safety glasses and gloves, to protect yourself from potential hazards.

b. Proper Training

Ensure that all operators receive adequate training and understand the machine’s functionality and safety features.

c. Machine Guards

Utilize machine guards to prevent accidental contact with moving parts and reduce the risk of injuries.

Frequently Asked Questions

1. What is a milling machine used for?

A milling machine is used for shaping and cutting materials like metal, plastic, and wood. It is widely used in industries such as automotive, aerospace, and manufacturing.

2. What are the main types of milling machines?

The main types of milling machines are vertical milling machines, horizontal milling machines, and CNC milling machines. Each type has its specific applications and advantages.

3. How do I maintain a milling machine?

Maintaining a milling machine involves regular inspections, proper lubrication, and cleaning. Following the manufacturer’s guidelines and conducting routine maintenance ensures the machine’s longevity and performance.

Understanding how a milling machine works is essential for anyone involved in manufacturing. By grasping its mechanics, components, and applications, you can appreciate the tremendous impact of this technology on various industries. For further reading, visit the official guide from CNC Masters.