When considering the purchase of a lathe, one of the first questions that come to mind is, how much do lathes cost? This is an essential question for hobbyists, small business owners, and large manufacturing firms alike. With lathes being a critical part of many machining processes, understanding the cost factors is vital to making an informed decision.

Understanding Lathe Machines

Lathes are versatile machines used in manufacturing to cut, shape, and form materials. They are essential for creating precise components and products across various industries. The cost of a lathe can vary greatly depending on several factors.

Different Types of Lathes

There are several types of lathes available in the market. Each type has its unique features and is suitable for different tasks:

- Wood Lathes

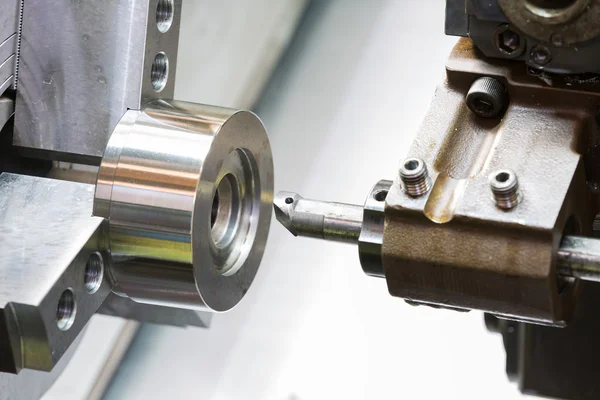

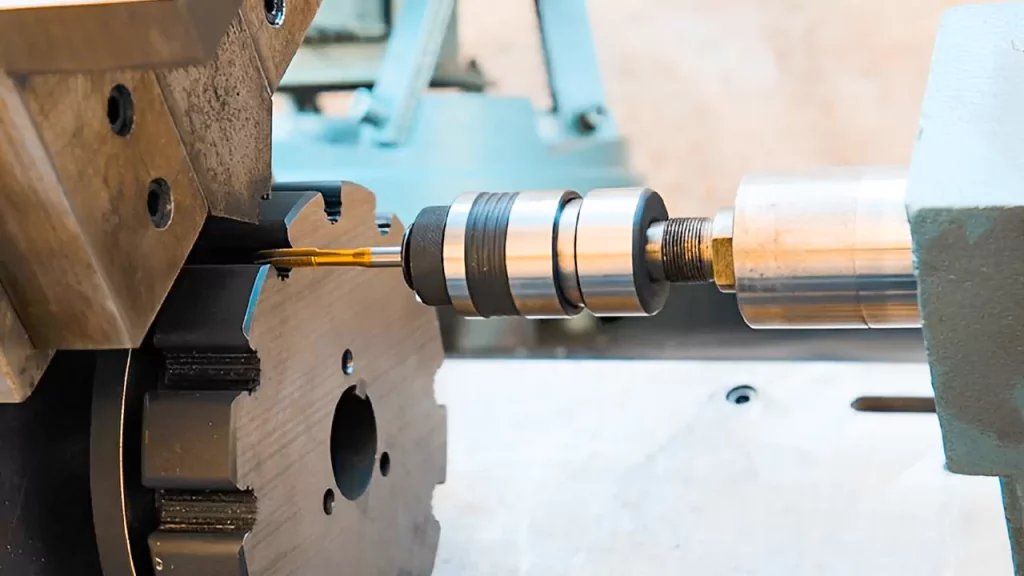

- Metal Lathes

- Mini Lathes

- CNC Lathes

Factors Affecting Lathe Costs

Several factors influence the cost of a lathe machine. Understanding these factors can help you choose the right lathe for your needs at the best price.

Type and Size

The type and size of the lathe are primary determinants of its cost. Larger, more complex machines like CNC lathes are generally significantly more expensive than smaller, simpler models like mini lathes or wood lathes.

Brand and Quality

The brand and quality of the lathe also play a crucial role in determining its price. Reputable brands with a history of reliability tend to be more expensive, but they also often offer better performance and durability.

Features and Capabilities

Lathes with advanced features such as computerized controls, digital readouts, and enhanced automation capabilities will cost more than basic models. Depending on your needs, investing in a lathe with specific features may be worthwhile.

New vs. Used

Purchasing a new lathe can be significantly more expensive than buying a used one. However, while used lathes can be more affordable, they might come with unknown histories and potential hidden issues.

Price Ranges for Different Lathes

To give you a better idea of how much you might spend, let’s look at the approximate price ranges for different types of lathes:

Wood Lathes

Wood lathes are generally more affordable, with prices ranging from $200 for entry-level models to $2,000 for high-end, professional-grade machines.

Metal Lathes

Metal lathes can be more expensive, typically ranging from $500 for small benchtop models to over $10,000 for larger, more advanced units.

Mini Lathes

Mini lathes are often the most affordable, with prices starting at around $100. High-quality versions can go up to $1,000.

CNC Lathes

CNC lathes are the most costly, with prices generally starting at $5,000 and reaching upwards of $100,000 depending on the size and capabilities of the machine.

Price vs. Value

It’s essential to consider both the price and value when shopping for a lathe. A lower-cost machine may be tempting, but it’s crucial to ensure it meets your needs and provides long-term reliability.

Consider Your Requirements

Think about what you’ll primarily use the lathe for and choose one based on those tasks. A small mini-lathe may be perfect for hobbyists, while a more advanced CNC lathe might be necessary for professional use.

Long-Term Investment

Consider the long-term costs, including maintenance, repairs, and potential upgrades. Investing in a higher-quality machine now could save you money in the future.

[dfollow href=’https://strobox.ai/advanced-stroboscopic-event-detection-in-semiconductor-wafer-polishing/’ rel=’dofollow’]Semiconductor Polishing Machines[/dollow] and other factors also play significant role in vary pricing with advance features have significant pricing.

Where to Buy Lathes

Several options are available for buying lathes, each with its advantages and considerations:

Online Marketplaces

Websites like Amazon, eBay, and specialized machinery marketplaces offer many new and used lathes. Buying online allows you to compare prices easily and read customer reviews.

Machinery Dealers

Local machinery dealers can provide personalized service and support. They often offer installation, training, and maintenance services.

Manufacturers

Purchasing directly from manufacturers can sometimes provide better deals and more customization options.

Making the Final Decision

When deciding on a lathe, take your time to research and compare. Consider all the factors mentioned above and choose a machine that best fits your needs and budget.

Seek Expert Advice

If you’re unsure, consulting with experts or experienced lathe users can provide valuable insights and recommendations.

Test Before You Buy

If possible, visit a dealer or manufacturer to see the lathe in action. This can help you understand its capabilities better and ensure it meets your expectations.

Check Reviews and Ratings

Reading reviews and ratings from other users can offer a real-world perspective on the lathe’s performance and reliability.

FAQs About Lathe Costs

Are used lathes a good investment?

Used lathes can be a good investment if they are in good condition and meet your needs. However, consider potential hidden issues and future repair costs.

How much maintenance do lathes require?

Maintenance varies by lathe type and usage. Regular cleaning, lubrication, and parts checks are essential for all lathes to ensure longevity and performance.

Can I finance the purchase of a lathe?

Yes, many dealers and manufacturers offer financing options, allowing you to spread the cost over time. Always check the terms and interest rates before committing.

For more detailed information on lathe machines, visit this guide on lathes.