How much is a milling machine? is a question many in the industrial and manufacturing sectors often ponder. The cost of a milling machine depends on several factors including its size, capabilities, and features it offers. In this detailed guide, we will delve into the different types of milling machines, and what influences their prices, and provide you with a comprehensive overview of what you need to know.

Milling machines are essential in today’s manufacturing landscape. Whether you are using them for simple projects or complex industrial tasks, understanding their cost and value proposition is vital for making educated purchasing decisions. This article will break down the costs involved and help you understand the importance of investing in the right machine for your needs.

1. Understanding Milling Machines

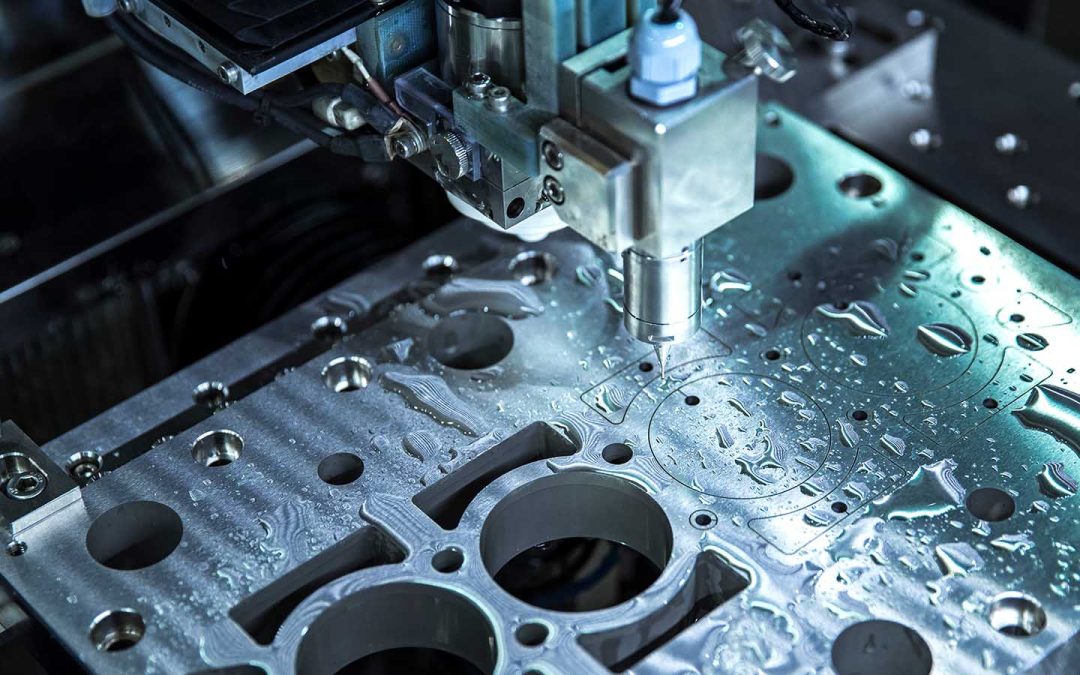

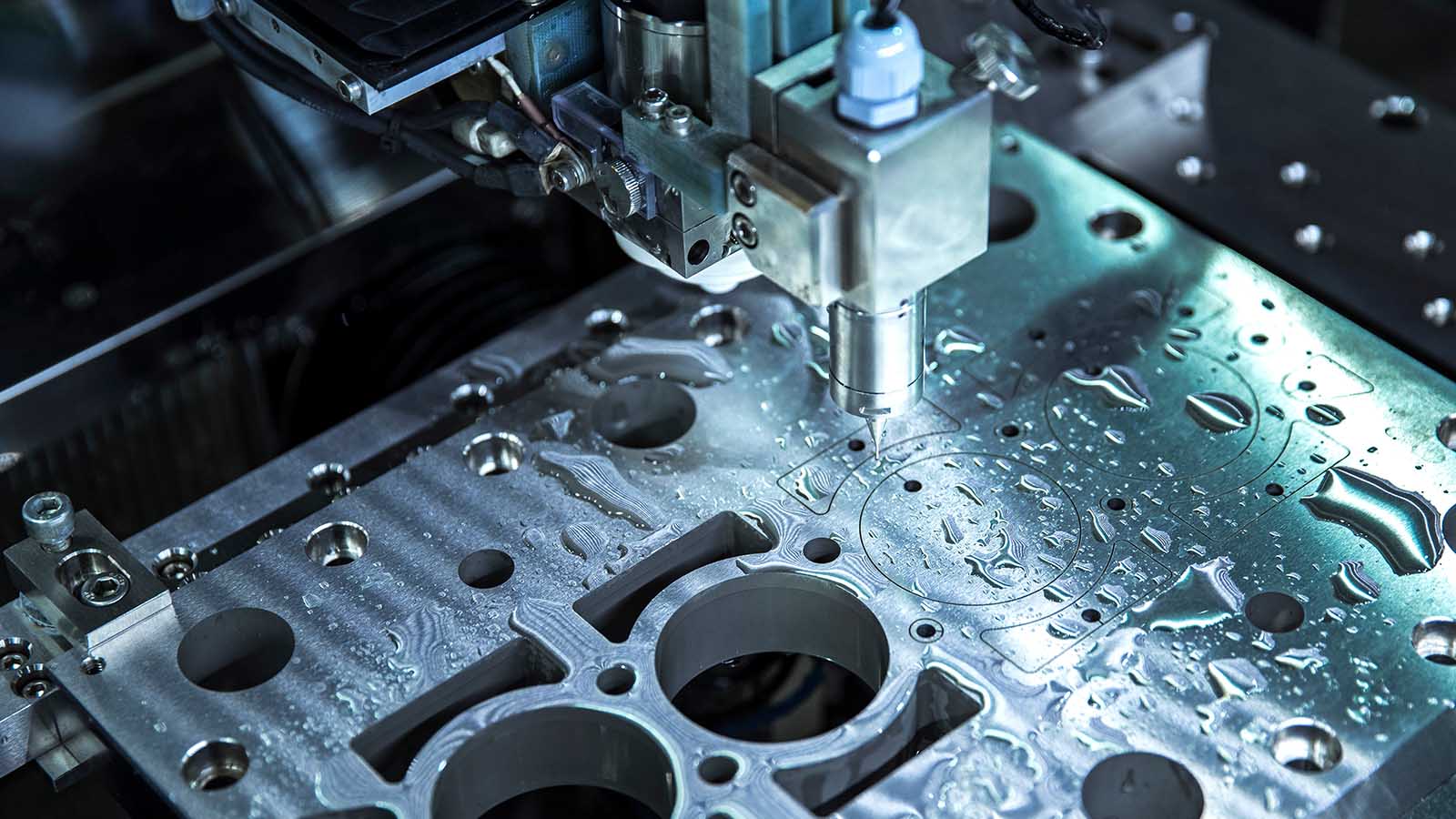

A milling machine is a tool used in the vertical or horizontal milling of a variety of metals. The machine works by using rotating cutters to remove material from a workpiece, shaping it into the desired form.

1.1 Types of Milling Machines

Milling machines come in different types, each designed for specific tasks.

- Vertical Milling Machines: These machines have a vertically oriented spindle and are excellent for plunge cuts and drilling.

- Horizontal Milling Machines: These machines have a horizontally oriented spindle and are perfect for heavier pieces and larger-scale projects.

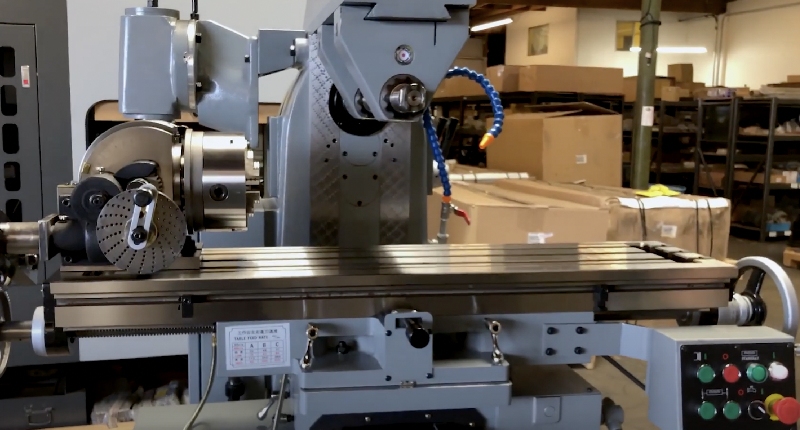

- Universal Milling Machines: A combination of both vertical and horizontal milling machines, offering versatility and efficiency.

2. Factors Influencing the Cost

Several elements can affect how much a milling machine costs. Here are some key factors:

- Brand: Well-known brands provide reliability but often come at a higher price.

- Features: Additional capabilities such as CNC control and advanced spindles can increase the price.

- Size: Larger, industrial-scale machines are generally more expensive than smaller, hobbyist models.

3. Price Ranges

Here’s a general price range for different types of milling machines:

- Entry-Level Milling Machines: $2,000 – $10,000

- Mid-Range Milling Machines: $10,000 – $50,000

- Industrial Milling Machines: $50,000 and up

4. Benefits of Investing in Quality Milling Machines

Investing in a quality milling machine offers numerous advantages:

- Efficiency: High-quality machines provide better efficiency and productivity.

- Precision: Accurate and precise cuts lead to better products.

- Durability: Long-lasting machines reduce the need for frequent replacements.

5. Industry Applications

Milling machines are used across various industries, including:

- Automotive: For manufacturing engine parts and components.

- Aerospace: Creating intricate parts for aircraft.

- Medical: Producing precise medical instruments.

6. Maintenance and Operating Costs

Owning a milling machine also involves maintenance and operational expenses. It’s important to consider these costs when making a purchase decision.

7. Used vs. New Milling Machines

Buying a used milling machine can offer cost savings, but it comes with trade-offs in terms of reliability and warranty. Ensure to perform a thorough inspection before opting for a used machine.

8. Milling Machines for Small Businesses

For small businesses, entry-level and mid-range machines are often most suitable, balancing cost with capabilities.

9. Safety Considerations

Always adhere to safety guidelines when operating milling machines to prevent accidents and ensure a safe working environment.

10. Tips for Buying a Milling Machine

When purchasing a milling machine, consider the following:

- Evaluate your specific needs.

- Research and compare different models.

- Consider the long-term return on investment.

Frequently Asked Questions (FAQs)

Q1: What is the average price of a milling machine?

A1: An average milling machine costs between $2,000 and $50,000 depending on its capabilities and features.

Q2: Is it worth buying used milling machines?

A2: Yes, but be sure to inspect the machine thoroughly and consider potential repair costs.

Q3: What industries use milling machines?

A3: Milling machines are used in automotive, aerospace, and medical industries, among others.

Conclusion

Investing in a milling machine requires careful consideration of its type, capabilities, and cost. By weighing the factors discussed, you can make an informed decision that meets your needs and budget. For more in-depth information on different kinds of industrial tools, check out this article.