Swiss lathes are revolutionizing the art of precision machining, delivering tremendous accuracy and efficiency in manufacturing intricate components.

In this detailed article, we’ll explore how Swiss lathes work and their crucial role in modern manufacturing. Whether you’re an industry professional or a curious reader, this deep dive into Swiss lathes will provide you with a comprehensive understanding of this remarkable technology.

What Makes Swiss Lathes Different?

Swiss lathes, also known as Swiss-type automatic lathes, are unique due to their sliding headstock and guide bushing construction. Unlike traditional lathes, the workpiece moves while the tooling remains fixed. This design offers significant advantages in terms of precision and efficiency.

The History of Swiss Lathes

The origin of Swiss lathes can be traced back to the need for high-precision watchmaking in Switzerland. The demand for intricately detailed watch components led to the development of these specialized machines.

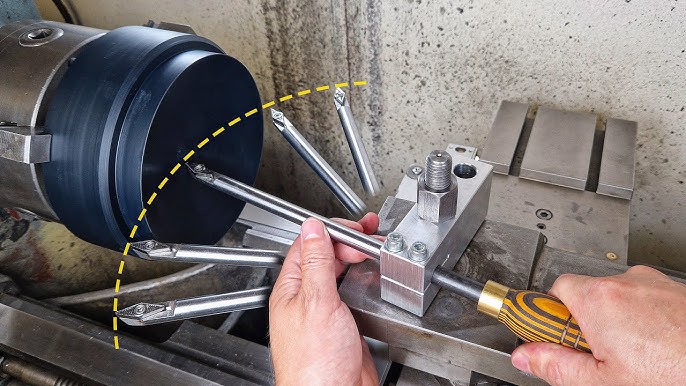

Core Components of Swiss Lathes

Here are some of the key components:

- Guide bushing: This ensures the workpiece remains stable during machining.

- Main spindle: Holds and rotates the workpiece.

- Tooling system: Houses various cutting tools.

- Control system: Modern Swiss lathes use CNC technology for precise control.

How Swiss Lathes Work

Initial Setup

The initial setup involves loading the workpiece into the guide bushing and securing it in the main spindle. The CNC control system is then programmed with the machining instructions.

Machining Process

During the machining process, the workpiece is fed through the guide bushing. The cutting tools execute various operations such as turning, drilling, and milling. The ability to perform multiple tasks in one setup reduces the need for additional handling and increases productivity.

Benefits of Swiss Lathes

Swiss lathes are renowned for their high accuracy, ability to handle small and complex parts, and efficiency in mass production. They are extensively used in industries such as aerospace, medical devices, and electronics, where precision is paramount.

Applications of Swiss Lathes

Aerospace Industry

Swiss lathes are used to manufacture components like fuel injectors, engine parts, and turbine blades. These parts require exceptional precision and consistency, provided by the capabilities of Swiss lathes.

Medical Industry

Medical devices like surgical instruments, implants, and dental tools are crafted using Swiss lathes. The high precision and ability to work with various materials, including metals and plastics, make Swiss lathes an ideal choice.

Electronics Industry

Swiss lathes are instrumental in producing electronic components such as connectors, sensors, and microchips. The intricate designs and small sizes of these components demand the accuracy provided by Swiss lathes.

Challenges in Operating Swiss Lathes

While Swiss lathes offer tremendous benefits, operating them requires specialized skills and knowledge. Proper maintenance and regular calibration are essential to ensure optimal performance.

Future of Swiss Lathes

The future of Swiss lathes looks promising with advancements in CNC technology and automation. Innovations like AI-driven tooling and real-time monitoring are expected to further enhance productivity and precision.

FAQ

What Materials Can Be Machined with Swiss Lathes?

Swiss lathes can machine a wide range of materials, including metals, plastics, and composites. Their versatility makes them suitable for various industries.

How Does a Swiss Lathe Compare to a Traditional Lathe?

The main difference lies in the sliding headstock and guide bushing of Swiss lathes, which provide greater precision and the ability to handle long, slender workpieces more effectively than traditional lathes.

Are Swiss Lathes Cost-Effective?

While the initial investment for Swiss lathes may be higher, their efficiency and precision can lead to significant cost savings in the long run, especially in mass production environments.

For more information on lathes, you can visit Landmark Tools and Testbook.

For more on Swiss lathes, check out our related articles on Paint & Coating, Genetic Analysis, and Semiconductor Manufacturing.