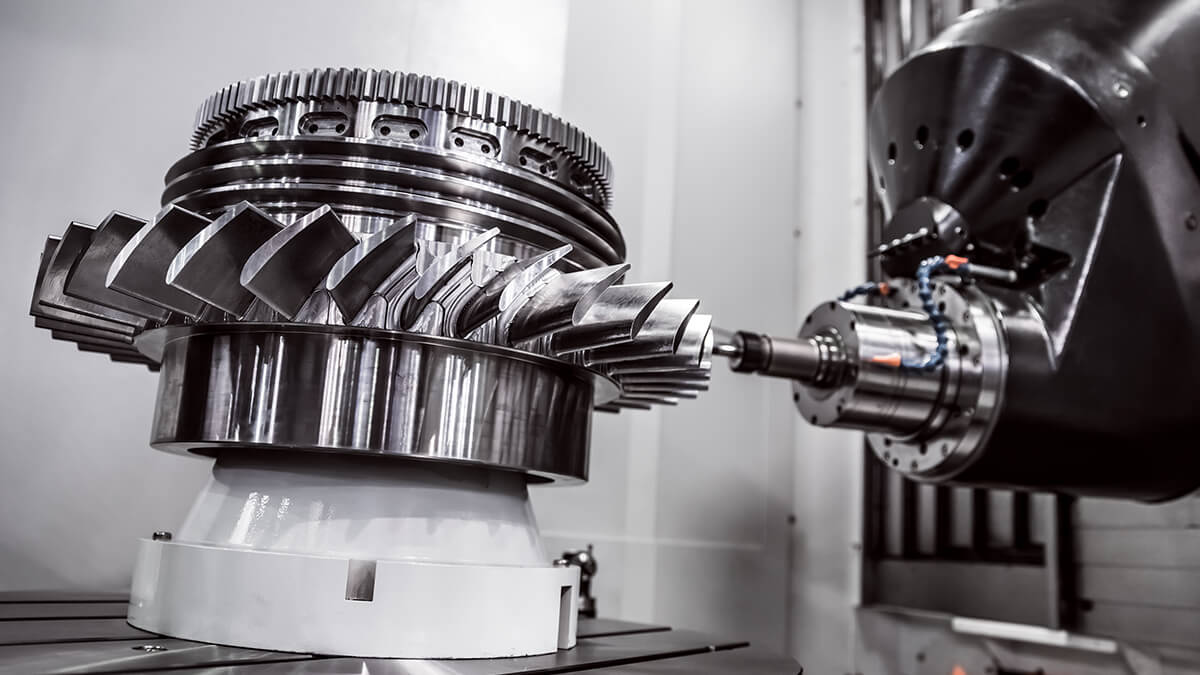

In the vast world of machining, understanding how to calculate milling machine speed is essential for achieving precision and efficiency. Speed calculations in milling are pivotal for industrial QA professionals, engineers, and machinists to ensure that production processes are optimized.

Understanding the Basics

Before diving into the specific calculations, it’s critical to understand the terminology and basic concepts related to milling machine speed. The primary keyword here, ‘how to calculate milling machine speed’, encompasses a few fundamental aspects: surface speed, spindle speed, and feed rate.

What is Surface Speed?

In machining, surface speed refers to the speed at which the tool engages with the material. It is typically measured in surface feet per minute (SFM) or meters per minute (m/min). This is a critical aspect that determines the effectiveness of the cutting process.

Spindle Speed

The spindle speed is the rotational speed of the spindle, measured in revolutions per minute (RPM). Understanding spindle speed is crucial because it directly influences the surface speed and, consequently, the quality of the cut.

Feed Rate

The feed rate is the distance that the tool advances during one revolution of the spindle. This rate impacts the cutting efficiency, tool life, and the quality of the machined surface.

Formula for Calculating Milling Machine Speed

Calculating milling machine speed involves using a specific formula to determine the spindle speed based on the desired surface speed and the diameter of the cutting tool.

Basic Formula for Milling Speed

To calculate the spindle speed (RPM) for a milling operation, use the formula:

RPM = (SFM x 12) / ( x Diameter)

This formula helps you determine the correct spindle speed to use, ensuring optimal performance and longevity of the cutting tool. Let’s break this down step-by-step.

Step-by-Step Calculation

Step 1: Determine the Surface Speed (SFM)

Surface speed is usually provided by the tool manufacturer or can be found in machining handbooks. For example, let’s assume a recommended surface speed of 400 SFM for a particular material.

Step 2: Measure the Diameter of the Cutting Tool

The diameter of the cutting tool is essential for calculating the spindle speed. For this example, assume a cutting tool with a diameter of 0.5 inches.

Step 3: Apply the Formula

Plug the values into the formula:

RPM = (400 x 12) / ( x 0.5)

Simplifying this equation:

RPM = 4800 / 1.57

RPM 3057

So, the spindle speed should be approximately 3057 RPM.

Factors Influencing Milling Speed

While the formula provides a good starting point, other factors can influence the milling speed, including:

Material of the Workpiece

Different materials require different cutting speeds. For instance, aluminum usually allows for higher speeds compared to steel.

Tool Material and Coating

The material and coating of the cutting tool also play a crucial role. High-speed steel (HSS) tools have different speed capabilities compared to carbide tools.

Machine Capacity

The capabilities of the milling machine itself, including power and rigidity, can impact the optimal speed.

Practical Considerations

When calculating milling machine speed, its essential to consider practical aspects such as:

Tool Wear and Lifespan

Running the tool at optimal speed minimizes wear and extends its lifespan.

Surface Finish

Appropriate speed settings ensure a better surface finish on the machined part.

Safety

Always follow the manufacturer’s guidelines and safety protocols to prevent accidents.

Advanced Speed Calculations

For more advanced applications, such as high-speed milling or complex materials, further adjustments may be necessary:

Speed Adjustments Based on Feed Rate

Fine-tuning the speed based on the feed rate and the desired quality of the cut is often required.

Using CNC Machines

Computer Numerical Control (CNC) machines can automatically adjust speeds, but understanding the manual calculations helps in setting up the programs accurately.

Conclusion

Understanding how to calculate milling machine speed is fundamental for anyone involved in the machining industry. By following the basic formula and taking into account various influencing factors, you can optimize your milling operations.

FAQs

How do I determine the surface speed for different materials?

Surface speed recommendations can be found in machining handbooks or provided by tool manufacturers. Different materials have specific surface speed requirements.

What is the role of feed rate in milling speed?

The feed rate influences the cutting efficiency and the quality of the machined surface. It should be considered along with the spindle speed for optimal performance.

Can I use the same speed settings for different tools?

No, different tools have different speed capabilities. Always refer to the tool manufacturer’s guidelines for specific speed recommendations.

For more information, you can refer to the Wikipedia on Milling or this CNC Masters guide.

For information on high-speed applications, see our articles on event detection, paint inspection, and wafer polishing.